Method for producing high-quality phosphoric acid and high-quality phosphogypsum by leaching rare earth-containing phosphate rock with regenerated phosphoric acid

A technology of phosphogypsum and phosphoric acid, applied in phosphogypsum, leaching phosphate rock with phosphoric acid to produce phosphoric acid, and rare earth fields, to reduce environmental pressure, improve economic benefits, and facilitate application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

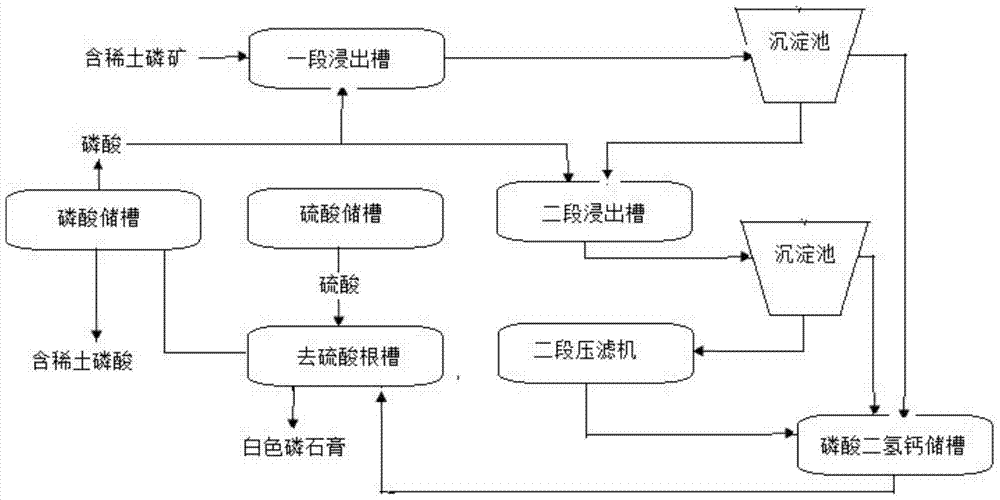

[0021] The rare earth-containing phosphate rock and the regenerated phosphoric acid are metered into the first-stage leaching tank together, so that the regenerated phosphoric acid and the rare-earth-containing phosphate rock undergo a one-stage leaching reaction. The reaction process condition is to control the liquid-solid ratio of the regenerated phosphoric acid and phosphorus concentrate to 8:1. ~15:1, reaction temperature 30℃~80℃, reaction time 2~6h; after a leaching reaction, add flocculant polyacrylamide to the slurry to separate the clear liquid from the slag slurry, and the clear liquid overflows to Calcium dihydrogen phosphate storage tank, the slurry is pumped to the second-stage leaching tank, and regenerated phosphoric acid is added to continue the leaching reaction. The reaction process conditions are to control the solid ratio of 8:1 to 15:1, and the reaction temperature is 30°C to 80°C. ℃, the reaction time is 2-6 hours; after the second-stage leaching reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com