Preparation method of methyl 4-acetamido-5-chloro-2-methoxybenzoate

A technology of methyl methoxybenzoate and acetamide, which is applied in the field of chemical synthesis, can solve the problems of large environmental pollution, unfavorable industrial production, and strong smell of acetic acid, and achieve the goals of saving transportation, saving raw material costs, and reducing waste solvents the effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

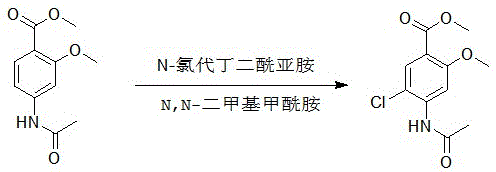

Image

Examples

Embodiment 1

[0030] Add 100g of N,N-dimethylformamide into a 1L reaction flask, add 50g of methyl 4-acetamido-2-methoxybenzoate, stir to dissolve, add 33g of N-chlorosuccinimide, slowly Raise the temperature to 35°C, keep the heat for 5 hours, then raise the temperature to 65°C, and hold the heat for 4 hours; after the reaction is completed, cool down to 0°C to crystallize for 8 hours, and shake off the material to obtain 4-acetamido-5-chloro-2-methoxybenzoic acid The crude methyl ester wet product and the N,N-dimethylformamide mother liquor are reserved for later use; the crude 4-acetamido-5-chloro-2-methoxybenzoic acid methyl ester wet product is added to 100g of deionized water, and the temperature is raised Heat at 50°C for 3h, cool down to 5°C, filter with suction, and dry to obtain 43g of off-white methyl 4-acetamido-5-chloro-2-methoxybenzoate, with a molar yield of 74.5% and an HPLC purity of ≥99.8% .

Embodiment 2

[0032] Add 150g of N,N-dimethylformamide into a 1L reaction flask, add 50g of methyl 4-acetamido-2-methoxybenzoate, stir to dissolve, add 50g of N-chlorosuccinimide, slowly Raise the temperature to 40°C, hold the reaction for 4 hours, then raise the temperature to 80°C, hold the reaction for 3 hours; after the reaction is completed, cool down to 0°C, hold the heat for 8 hours, and shake off the material to obtain 4-acetamido-5-chloro-2-methoxybenzene Methyl formate crude wet product, N,N-dimethylformamide mother liquor reserved for future use; 4-acetamido-5-chloro-2-methoxymethyl benzoic acid crude wet product was added to 100g deionized water, Heat up to 50°C for 4 hours, cool down to 5°C, filter with suction, and dry to obtain 47.5g of off-white methyl 4-acetamido-5-chloro-2-methoxybenzoate, with a molar yield of 82.7%, HPLC purity≥ 99.8%.

Embodiment 3

[0034] Add 50g of N,N-dimethylformamide into a 1L reaction flask, add 50g of methyl 4-acetamido-2-methoxybenzoate, stir to dissolve, add 25g of N-chlorosuccinimide, slowly Raise the temperature to 45°C, heat-retain for 4 hours, then raise the temperature to 60°C, heat-retain for 5 hours; after the reaction is completed, cool down to 0°C, heat-preserve and crystallize for 8 hours, and shake off the material to obtain 4-acetamido-5-chloro-2-methoxybenzene Methyl formate crude wet product, N,N-dimethylformamide mother liquor reserved for future use; 4-acetamido-5-chloro-2-methoxymethyl benzoic acid crude wet product was added to 100g deionized water, Heat up to 50°C for 3 hours, cool down to 5°C, filter with suction, and dry to obtain 45.1 g of off-white methyl 4-acetamido-5-chloro-2-methoxybenzoate, with a molar yield of 78.2%, HPLC purity ≥ 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com