While-drilling remote control type multi-stage bent-angle-adjustable screw drilling tool

A screw drilling tool and remote control technology, which is applied in the field of multi-stage angle-adjustable screw drilling tools with remote control while drilling, can solve the problems of limited change range of mechanical properties of the drill bit, inability to meet high build-up rates, and high processing technology requirements. Achieve important social value and economic value, reduce energy consumption and overall cost, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

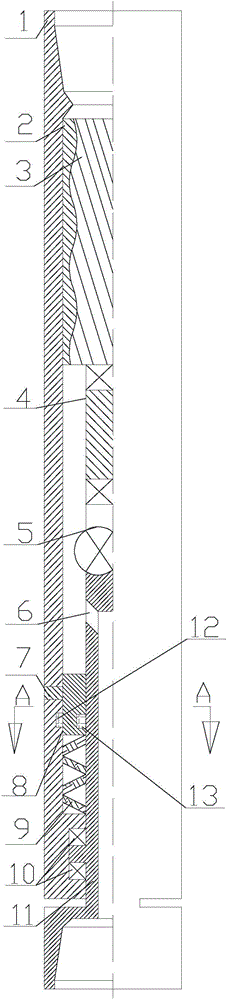

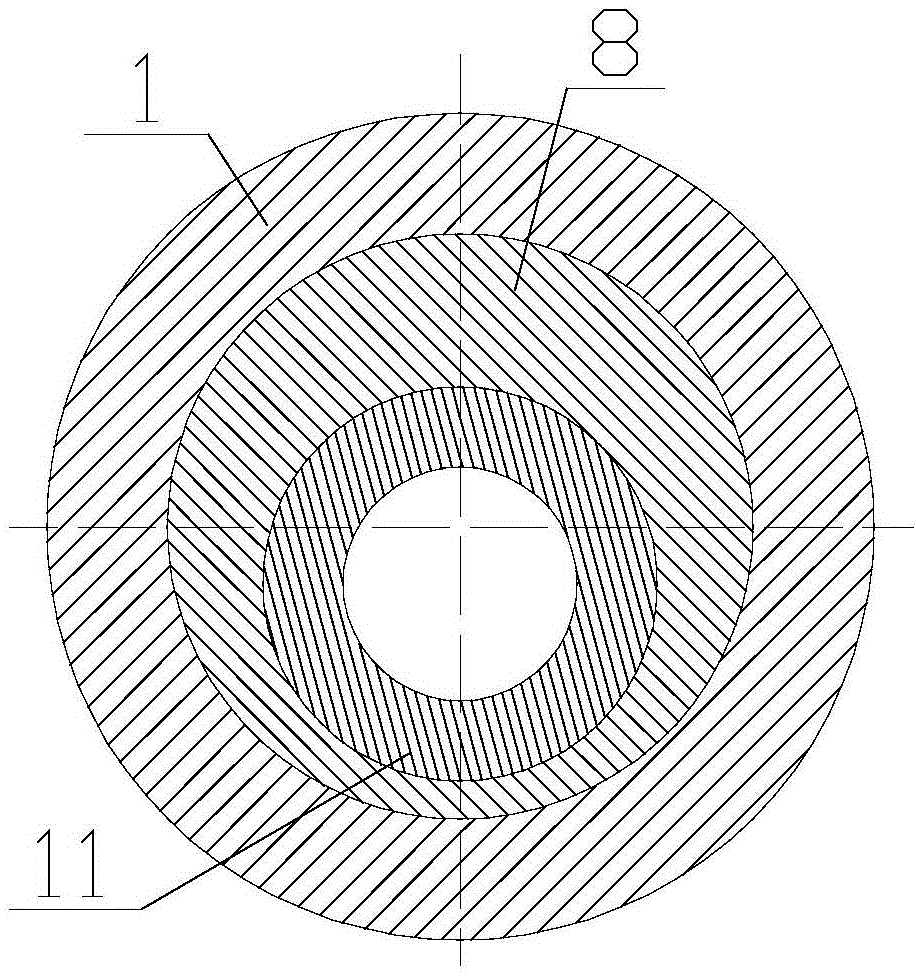

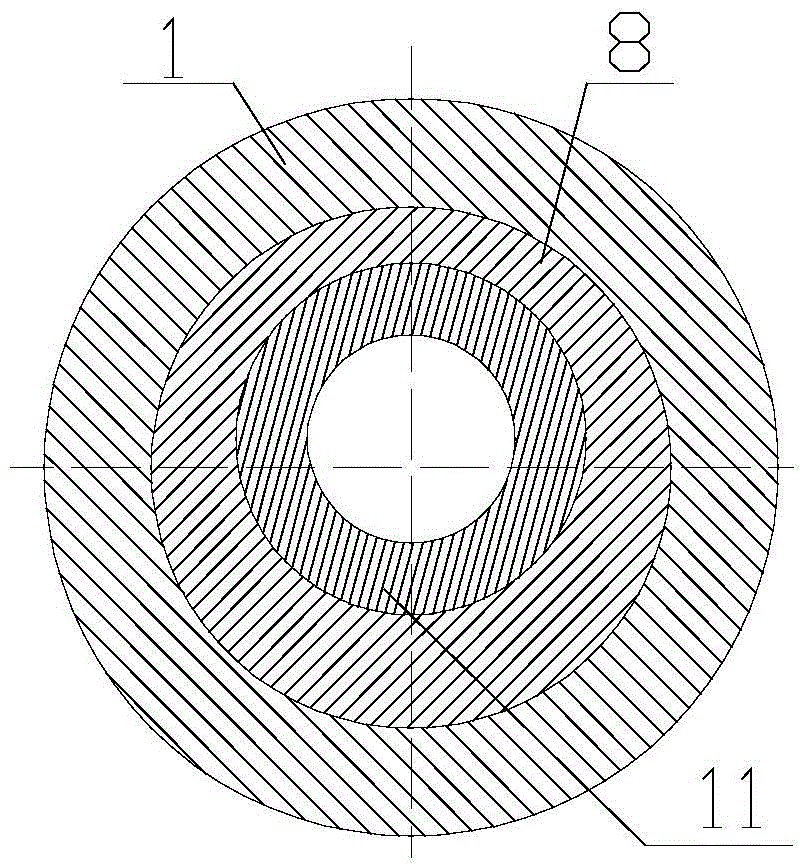

[0020] Such as figure 1 , the stator 2 is installed on the inner wall of the housing 1, the rotor 3 cooperates with the stator 2, the coupling 4 is connected to the lower end of the rotor 3, the knuckle 5 is connected between the coupling 4 and the output shaft 11, and the output shaft 11 is processed with side The through hole 6, the positioning pin 7 is installed on the housing 1, the regulator 8 is installed between the housing 1 and the output shaft 11, the positioning pin 7 is matched with the positioning groove 12 on the regulator 8, and the spring 9 is installed on the regulator 8 In the lower part, a bearing 10 is installed between the output shaft 11 and the housing 1 , and sealing devices 12 and 13 are respectively installed between the regulator 8 and the housing 1 and the output shaft 11 . As shown in Figures 2 and 3, the regulator 8, the output shaft 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com