Automotive double-fuel system using natural gas

A dual-fuel system and natural gas technology, which is applied in the direction of charging system, fuel injection device, combustion engine, etc., can solve the problems of inspection and maintenance requiring professionals, low attractiveness of diesel vehicle users, and low natural gas replacement rate, etc., to achieve Easy to maintain independently, easy to refit, high oil replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

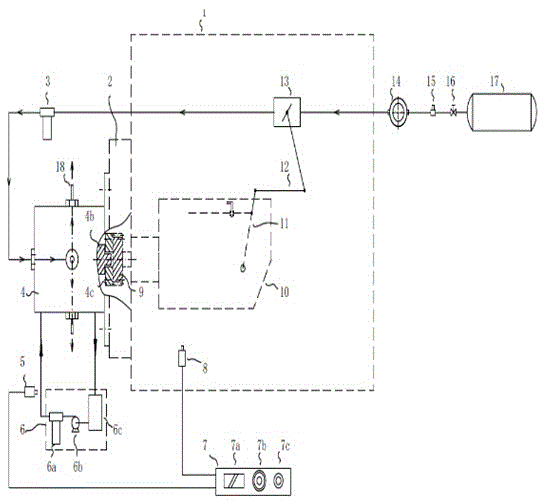

[0020] Such as figure 1 , figure 2 As shown, the present invention is implemented on a Cummins 6BT118 diesel vehicle, including a diesel engine, a natural gas supply device, a natural gas timing injection distributor 4, a fuel injection pump 10, a lubricating device and a control device; the natural gas timing injection distributor 4 is connected to the fuel injection pump 10 , the lubricating device 6 is connected with the natural gas timing injection distributor 4 through a lubricating circuit; the control device includes a control instrument panel 7 and an alarm.

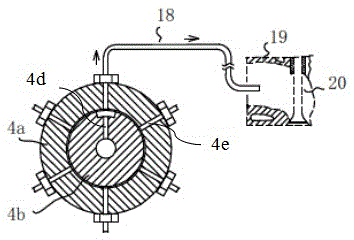

[0021] The natural gas supply device includes a connected natural gas bottle 17, a manual shut-off valve 16, an electromagnetic valve 15, a pressure reducing valve 14, a natural gas control butterfly valve 13 and a natural gas precision filter 3; the natural gas timing injector 4 includes a transmission sleeve 4c, a distributor shaft 4b and The distributor body 4a; the transmission sleeve 4c is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com