Alloy structure steel die-forged wheel hub of automobile engine cooling water pump

A technology of alloy structural steel and automobile engine, which is applied in the direction of machines/engines, liquid fuel engines, pumps, etc., can solve the problems of no toughness and easy fracture, and achieve the effects of not easy to break, prolong life, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

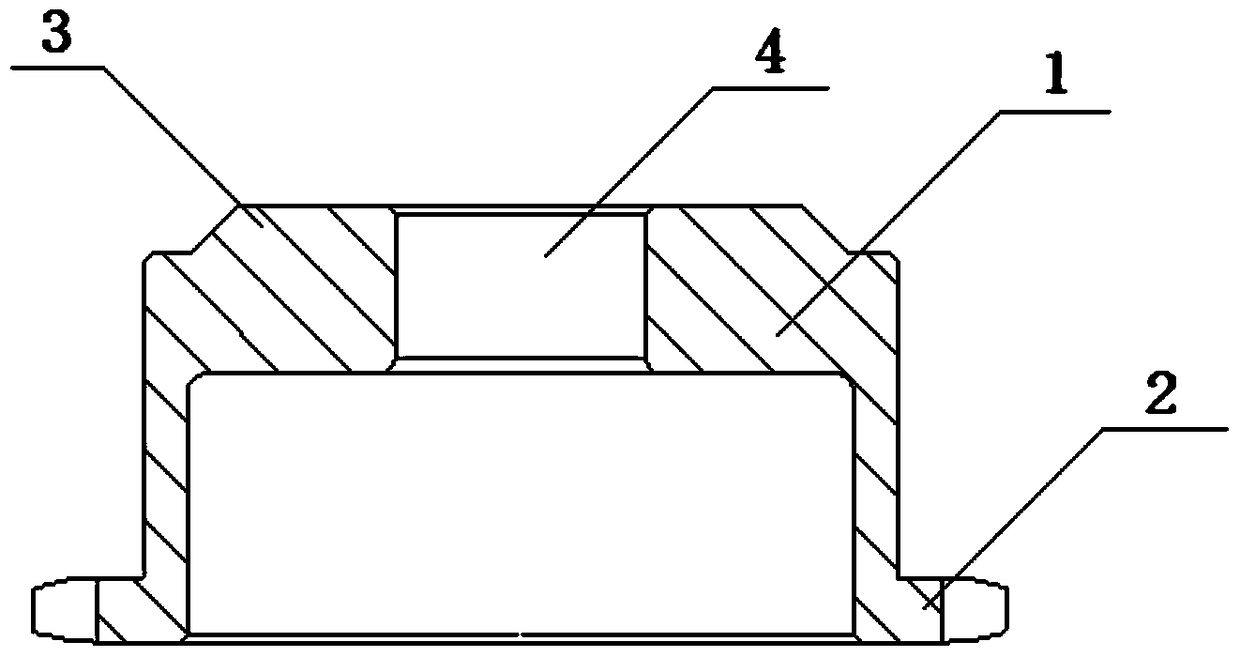

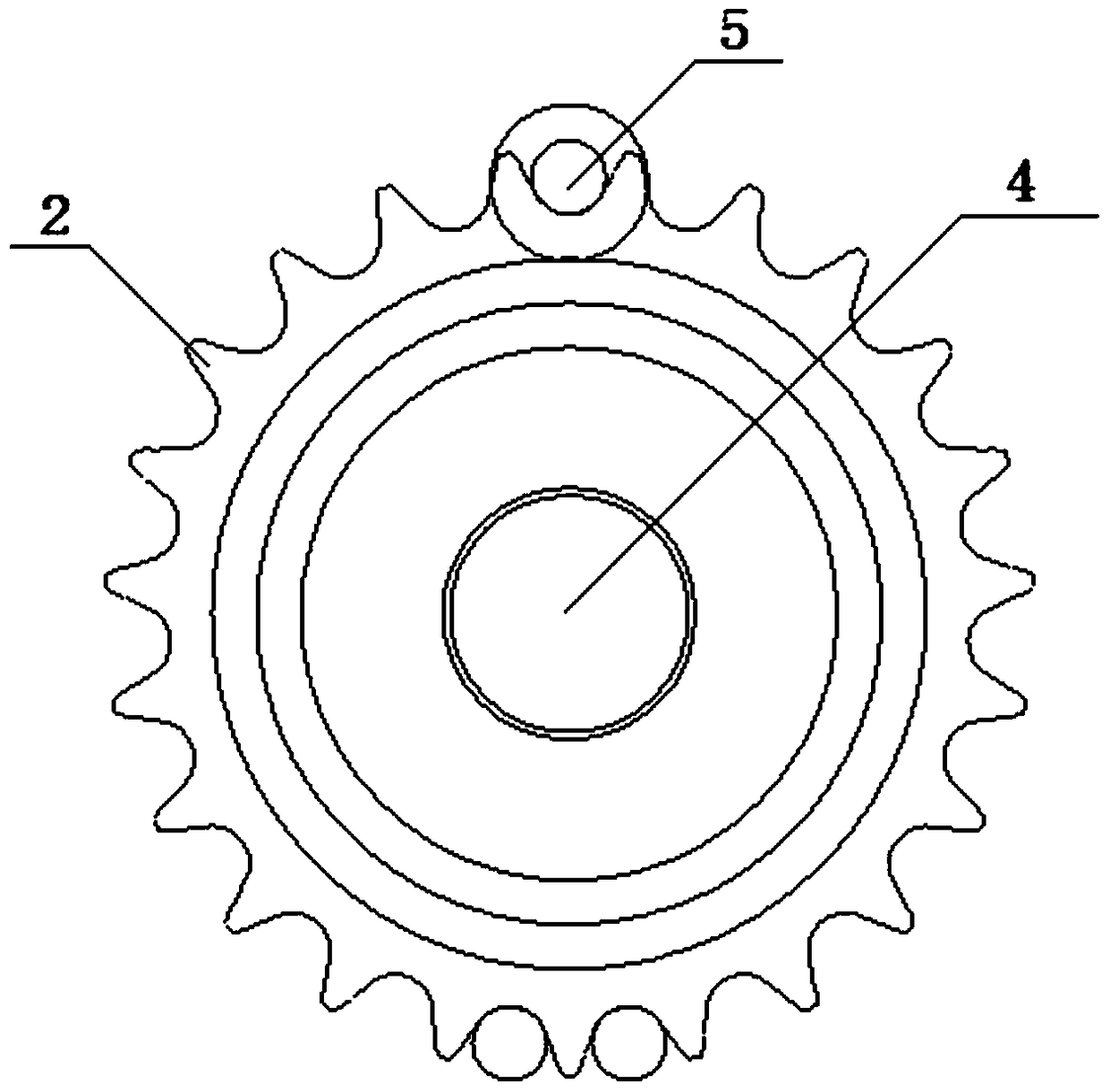

[0033] The one provided by this embodiment has a structure such as figure 1 As shown, the alloy structural steel die-forged wheel hub of the automobile engine cooling water pump includes a cylindrical shell 1 and the cylindrical shell 1 is a hollow structure with a circular opening on the bottom surface, and the bottom edge of the cylindrical shell 1 extends horizontally outward. There is a circle of protruding parts 2, and the number of protruding parts 2 is 23 and arranged at equal intervals along the circumference of the side of the cylindrical shell 1;

[0034] The upper surface of the cylindrical shell 1 is also provided with a circular protrusion 3 and the circular protrusion 3 and the upper surface of the cylindrical shell 1 are concentric circles, and a through hole 4 is also provided in the center of the cylindrical shell 1 , the through hole 4 runs through the upper surface of the circular protrusion 3 and the cylindrical shell 1;

[0035] In a circle of protruding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com