Automatic assembly and disassembly type mutual inductance power supply device of high-voltage overhead line

An automatic loading and unloading, high-voltage overhead technology, used in circuit devices, battery circuit devices, current collectors, etc., can solve the problems of high external environmental influence factors, prolonged off-line time of line inspection devices, and inability to perform line inspection tasks. The effect of improving operational reliability and sustainability, improving range and flexibility, and improving battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

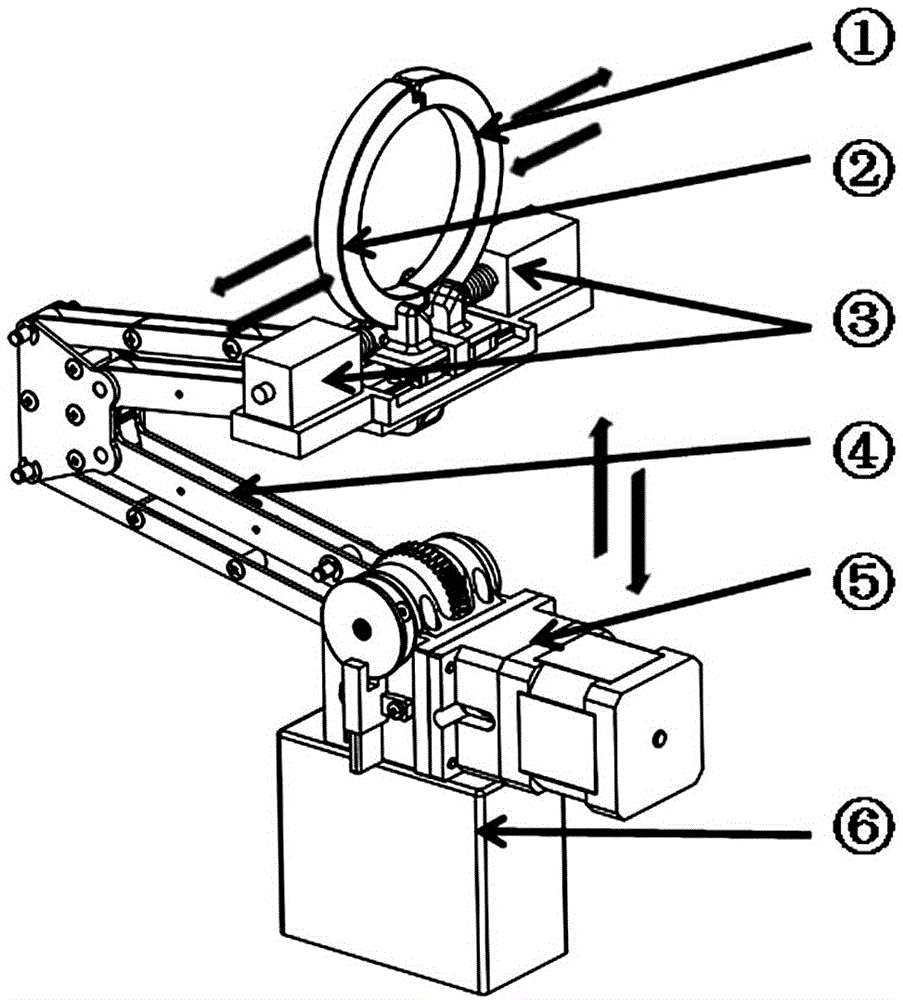

[0028] Example: figure 1 As shown, the automatic loading and unloading type high-voltage mutual induction power-taking device of the present invention mainly includes: a mutual induction iron core 11, a mutual induction coil 12, an electromagnet 13, a lifting frame 14, a lifting motor 15, and a device support 16; wherein the lifting frame 14 is the multi-link mechanism driven by the worm gear and worm, which has the advantages of high repeat positioning accuracy and light weight. At the same time, the worm gear and worm mechanism has self-locking performance, and its working state is guaranteed by its own structure. It does not need the lifting motor 15 to work all the time, which has the advantage of energy saving .

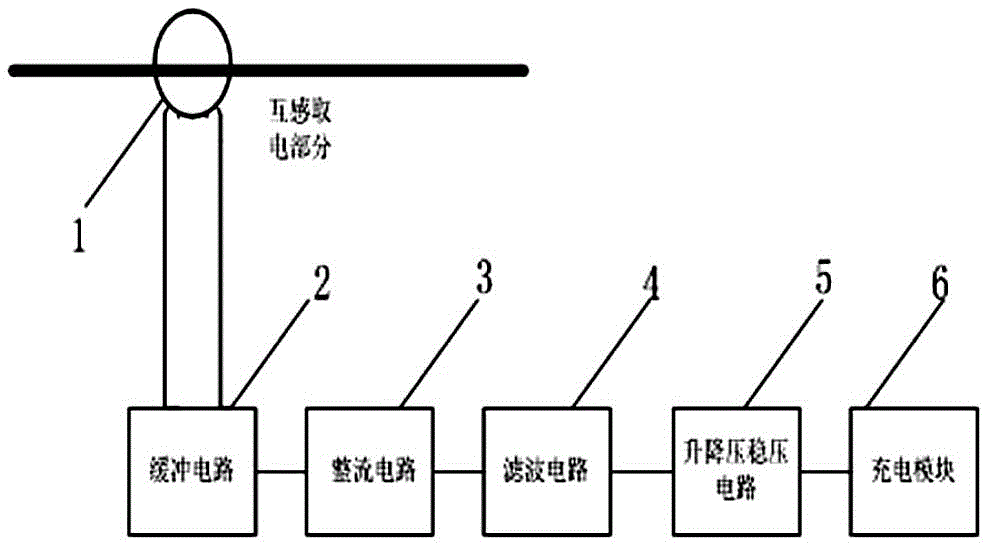

[0029] figure 2 As shown, the mutual inductance power taking in the present invention includes a power taking part 21 , which is a buffer circuit 22 , a rectifier circuit 23 , a filter circuit 24 , a buck-boost voltage regulator circuit 25 , and a rechargeable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com