clamping spring

A technology of clamping springs and clamping edges, which is applied in the direction of clamping/spring connection, fixed connection, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

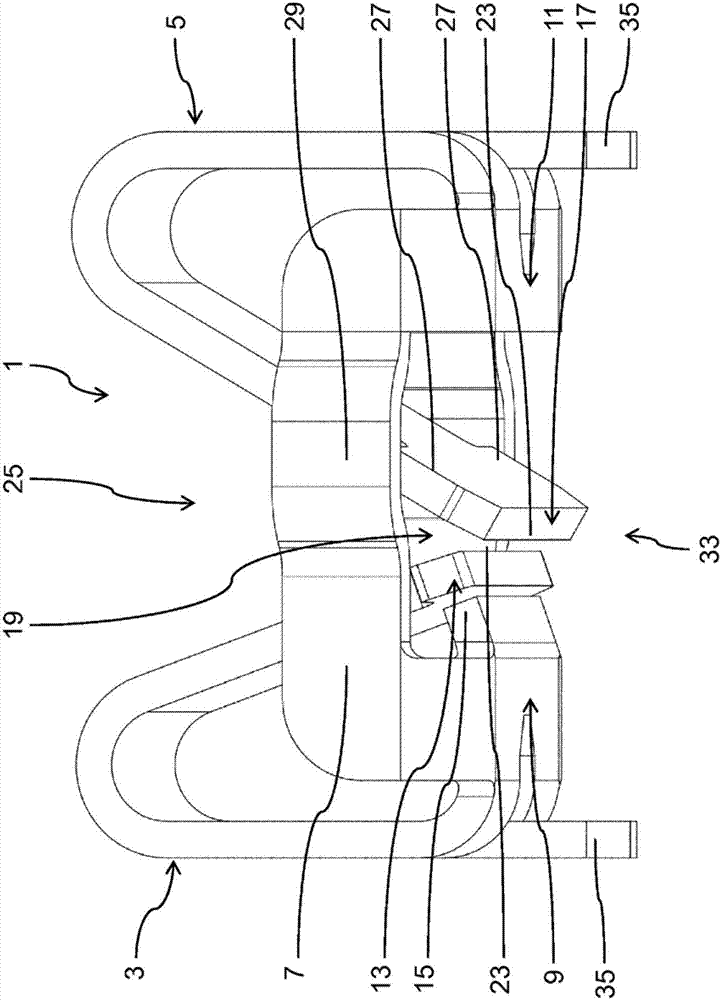

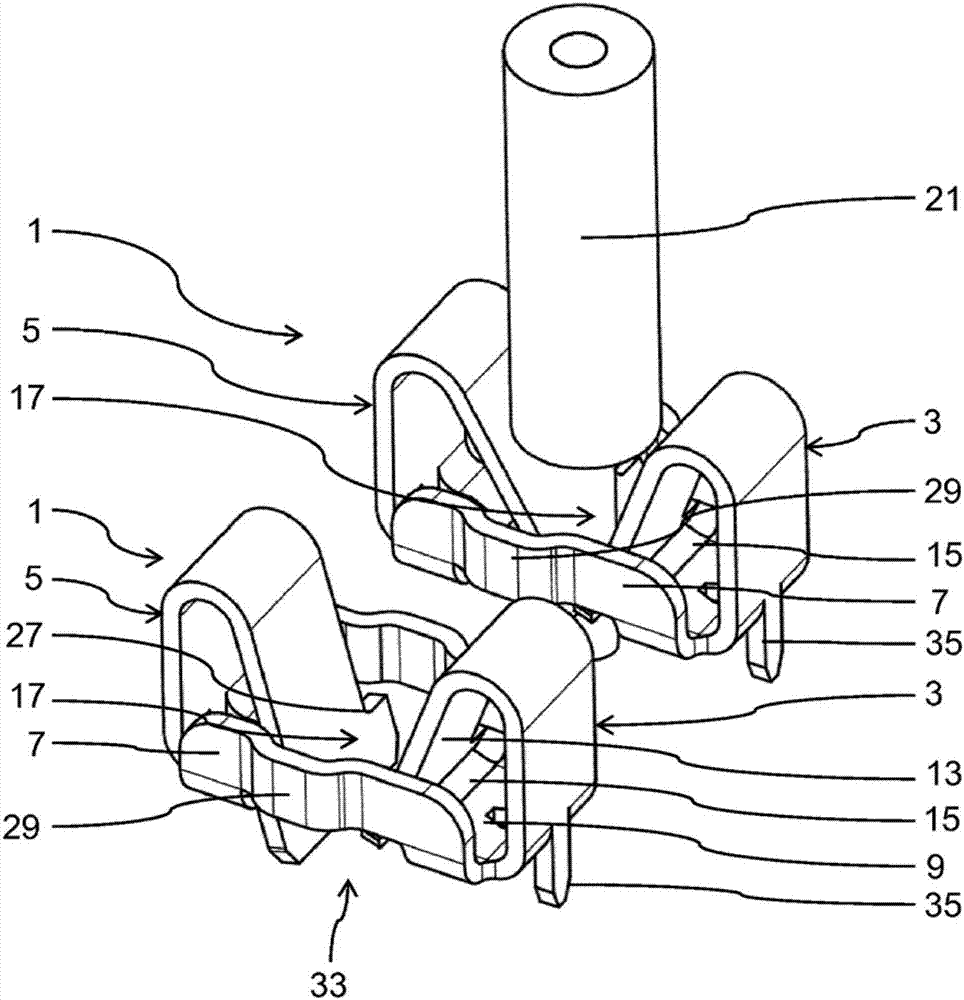

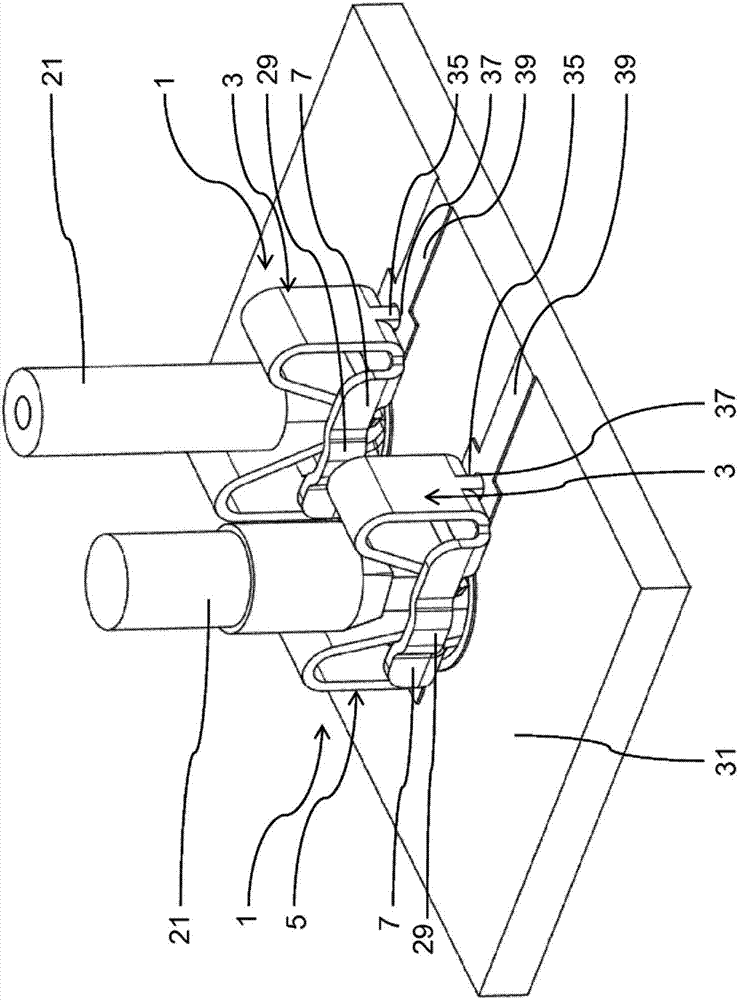

[0028] figure 1 and 2 A clamping spring 1 according to the invention according to a first preferred embodiment is shown. The clamping spring 1 is formed as a one-piece plate-shaped part from spring steel with galvanic copper coating and tin plating and is produced by stamping and bending.

[0029] The clamping spring 1 comprises a fixed clamping leg 3 , a spring leg 5 and two guide parts 7 . The guide part 7 is designed as a connecting part, which is connected to the end 9 of the clamping leg 3 and the end 11 of the spring leg 5 .

[0030] The clamping edge 3 is formed as an essentially elongated plate-shaped part bent in the shape of a hook and loop such that its two ends 9 , 13 approach each other. Such as figure 1 As shown in detail in , the clamping leg 3 has on its fixed end 9 a projection 15 designed as a clamping part and forms a clamping clamp for the other free end 13 of the clamping leg 3 .

[0031] The elastic side 5 is also formed as a substantially elongated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com