Dust removal structure of electrostatic purifier

A purifier, electrostatic technology, applied in the field of electrostatic purifier dust removal structure, can solve the problems of uneven electric field strength, easy oil accumulation, complicated manufacturing, etc., achieve good uniformity of electric field strength, save material and light weight, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

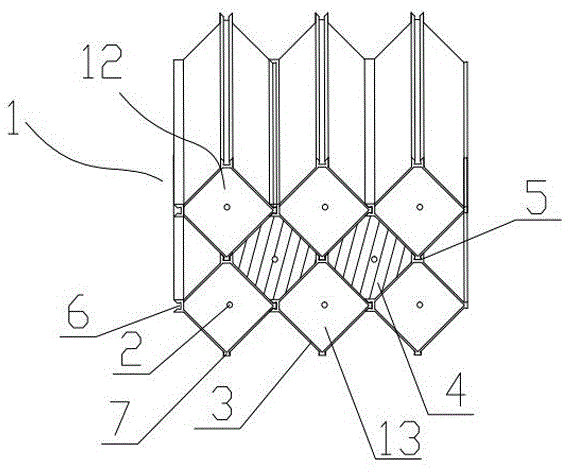

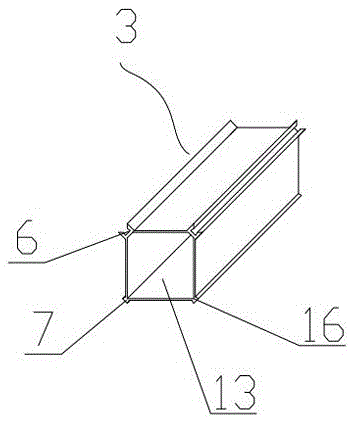

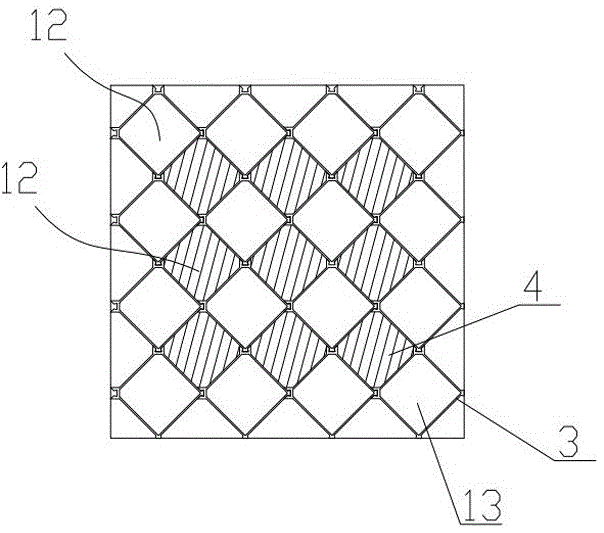

[0034] exist figure 1 , image 3 In the shown embodiment, a dust removal structure of an electrostatic purifier includes a dust collecting pole 1 and a discharge pole 2, the dust collecting pole 1 includes several dust collecting pole units 12, and the dust collecting pole unit 12 consists of several dust collecting pole monomers The inner cavity 13 of 3 is formed by the dust collection pole enclosure chamber 4, the dust collection pole enclosure chamber 4 is formed by the outer wall of the dust collection pole monomer 3, and the dust collection pole monomers 3 are plugged and connected with each other. The dust collection pole unit 3 is a pipe fitting profile formed in one piece, the dust collection pole unit 3 is a single-hole pipe fitting, and the cross section of the dust collection pole unit 3 is a square structure (see figure 2 ), four connecting ribs 16 are arranged on the outer wall of the dust-collecting pole unit 3, and a cavity 13 is provided inside the dust-colle...

Embodiment 2

[0041] exist Figure 5 , Figure 7 In the shown embodiment, a dust removal structure of an electrostatic purifier includes a dust collecting pole 1 and a discharge pole 2, the dust collecting pole 1 includes several dust collecting pole units 12, and the dust collecting pole unit 12 consists of several dust collecting pole monomers The inner cavity 13 of 3 is formed by the dust collection pole enclosure chamber 4, the dust collection pole enclosure chamber 4 is formed by the outer wall of the dust collection pole monomer 3, and the dust collection pole monomers 3 are plugged and connected with each other. The dust collection pole unit 3 is a pipe fitting profile formed in one piece, the dust collection pole unit 3 is a single-hole pipe fitting, and the cross section of the dust collection pole unit 3 is a square structure (see figure 2 ), four connecting ribs 16 are arranged on the outer wall of the dust-collecting pole unit 3, and a cavity 13 is provided inside the dust-col...

Embodiment 3

[0047] exist Figure 8 , Figure 9 In the shown embodiment, a dust removal structure of an electrostatic purifier includes a dust collecting pole 1 and a discharge pole 2, the dust collecting pole 1 includes several dust collecting pole units 12, and the dust collecting pole unit 12 consists of several dust collecting pole monomers The inner cavity 13 of 3 is formed by the dust collection pole enclosure chamber 4, the dust collection pole enclosure chamber 4 is formed by the outer wall of the dust collection pole monomer 3, and the dust collection pole monomers 3 are plugged and connected with each other. The dust collection pole unit 3 is a pipe fitting profile formed in one piece. The dust collection pole unit 3 is a double-hole pipe fitting. The cross section of the dust collection pole unit 3 is two square structures connected by edges on the diagonal. Six connecting ribs 16 are provided on the outer wall of the pole unit 3 , and two cavities 13 are provided inside the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com