Forming method of nickel-based high-temperature alloy multi-step large special-shaped ring part

A technology of nickel-based superalloy and special-shaped ring, applied in metal rolling, metal processing equipment and other directions, can solve the problems of affecting the forming effect, unreasonable matching of billet and die, unreasonable billet or die design, etc., to overcome the sudden change of section more area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] The main chemical element content (percentage by weight) of the alloy is: C content ≤ 0.08%, Cr content 17.0% ~ 21.0%, Ni content 50.0% ~ 55.0%, Co content ≤ 1.0%, Mo content 2.80% ~3.30%, Al content 0.30%~0.70%, Ti content 0.75%~1.15%, Nb content 4.75%~5.50%, B content ≤0.006%, Mg content ≤0.01%, Mn content ≤0.35 %, Si content ≤0.35%, P content ≤0.015%, S content ≤0.015%, Cu content ≤0.30%, Ca content ≤0.01%, Pb content ≤0.0005%, Se content ≤0.0003% , The balance is Fe.

[0033] The steps of this method are as follows:

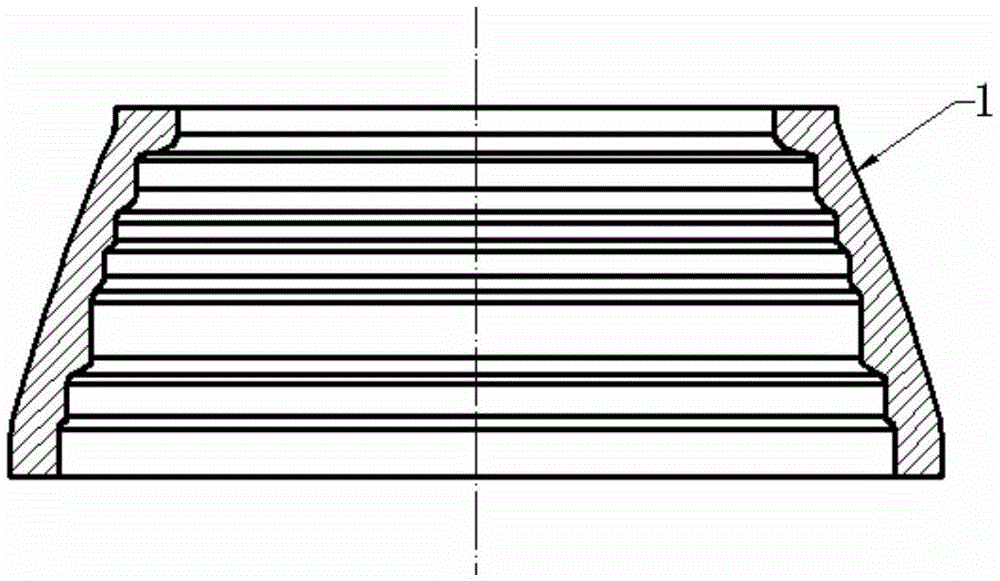

[0034] Step 1: Prepare intermediate ring blank

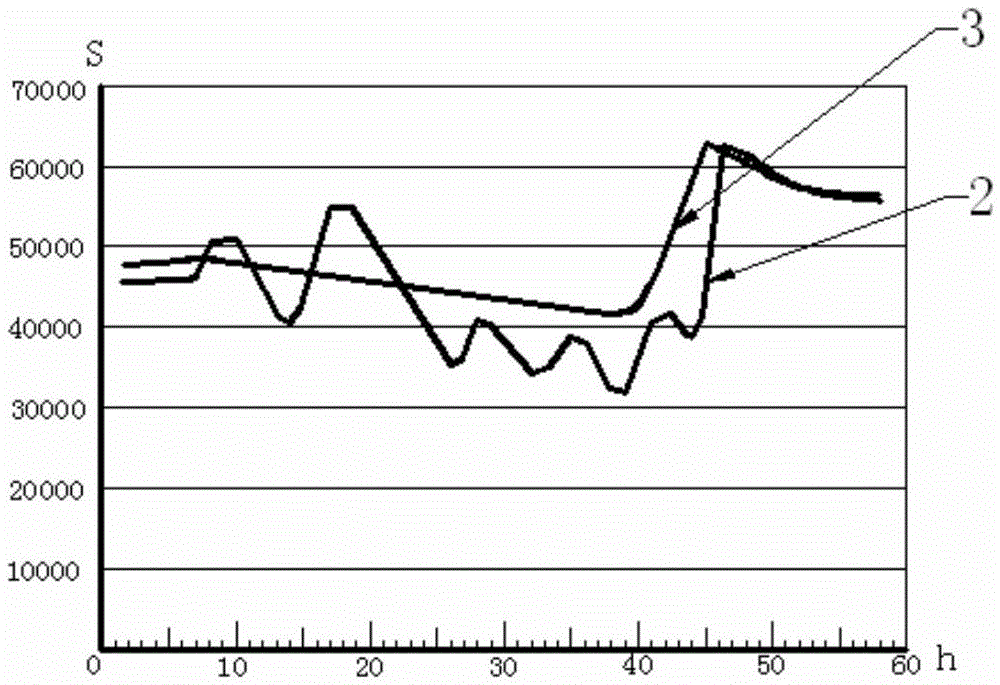

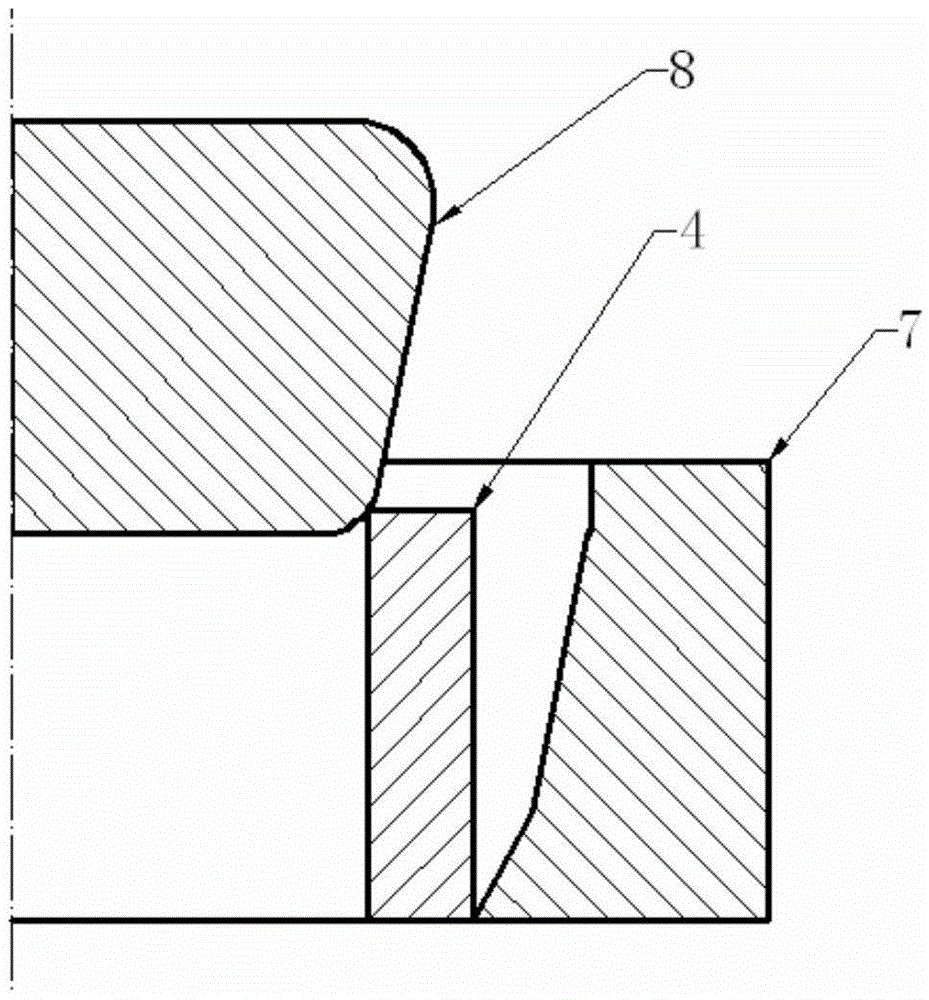

[0035] Such as figure 1 As shown, according to the structural characteristics of nickel-based superalloy multi-step large-scale special-shaped ring 1, the cross-section of the forging is cut layer by layer equidistantly from the height direction with the help of drawing software, and the cross-sectional area data of multi-step large-scale special-shaped ring 1 is obtained and curve 2 is drawn. ,Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com