Closed-loop control system for taper of crystallizer

A closed-loop control and crystallizer technology, which is applied in the field of metallurgical continuous casting equipment, can solve the problem that the taper of the mold cannot be directly measured, and achieve the effects of simple structure, flexible adjustment, and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

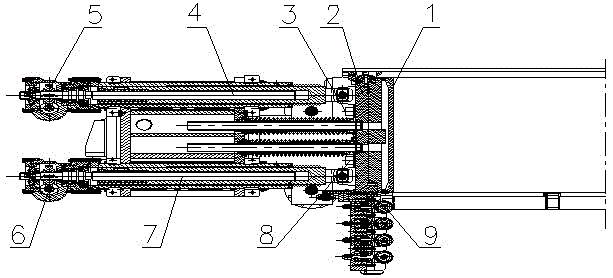

[0017] In order to overcome the problem that the taper of the crystallizer cannot be directly measured in the existing system, and the transmission gap in the mechanical equipment and the wear between the parts cannot be completely eliminated, the present invention provides a method such as figure 1 The mold taper closed-loop control system is shown, so the mold taper can be detected continuously and with high precision. There are no special requirements for using hydraulic cylinder control or servo motor control. The crystallizer taper measurement is accurate and is a direct measurement method. The measured crystallizer taper can not only be used for static and dynamic control, but its equipment cost is low, which is obviously better than the cost of the displacement sensor.

[0018] Mold taper closed-loop control system, including mold narrow side copper plate 1 and support plate 2, mold narrow side copper plate 1 and copper plate back plate are fastened together by screws, ...

Embodiment 2

[0022] Based on Embodiment 1, in this embodiment, the crystallizer foot roll 9 is installed on the lower end of the support plate 2 .

[0023] The crystallizer foot roll 9 is mounted on the support plate 2 by bolts.

[0024] The upper screw mechanism 4 and the lower screw mechanism 7 are keyed together with the lower worm gear reducer 6 and the upper worm gear reducer 5 respectively.

[0025] The upper inclination sensor 3 and the lower inclination sensor 8 are mounted on the support plate 2 by screws.

[0026] The upper inclination sensor 3 and the lower inclination sensor 8 measure directly and with high precision, and are highly portable, and can be used for equipment transformation and upgrading.

[0027] Through the inclination sensor installed on the support plate 2 of the narrow side of the crystallizer, the taper of the copper plate of the narrow side of the crystallizer can be detected in real time, so as to carry out online adjustment and real-time detection on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com