Lathe chuck for aluminum alloy hub

A technology for aluminum alloy wheels and lathe chucks, which is applied in the direction of clamping, chucks, wheels, etc., can solve the problems of increasing the workload of operators, wasting processing time, reducing production output, etc., and achieves good positioning consistency and stable operation , Clamping stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

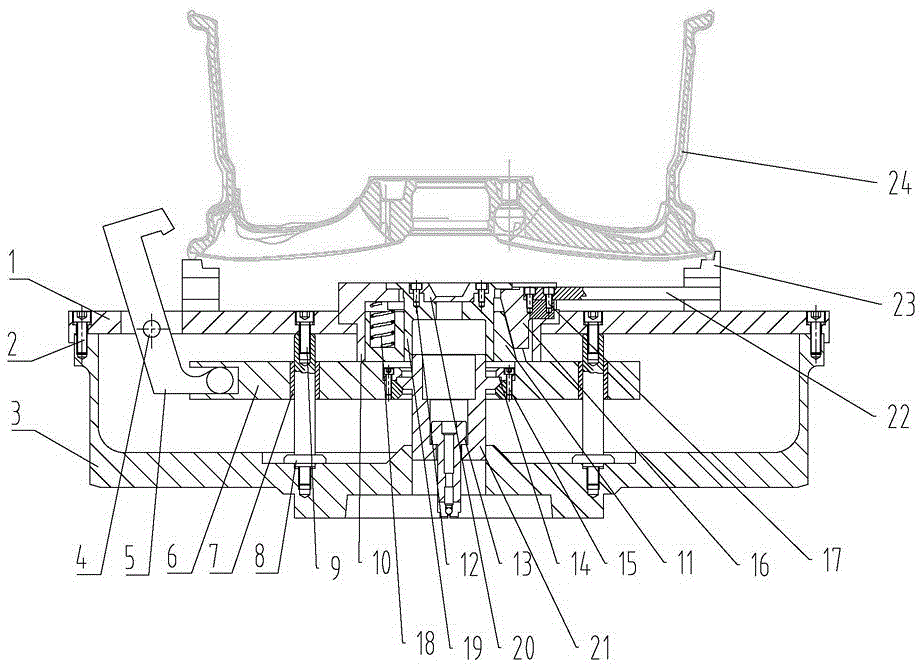

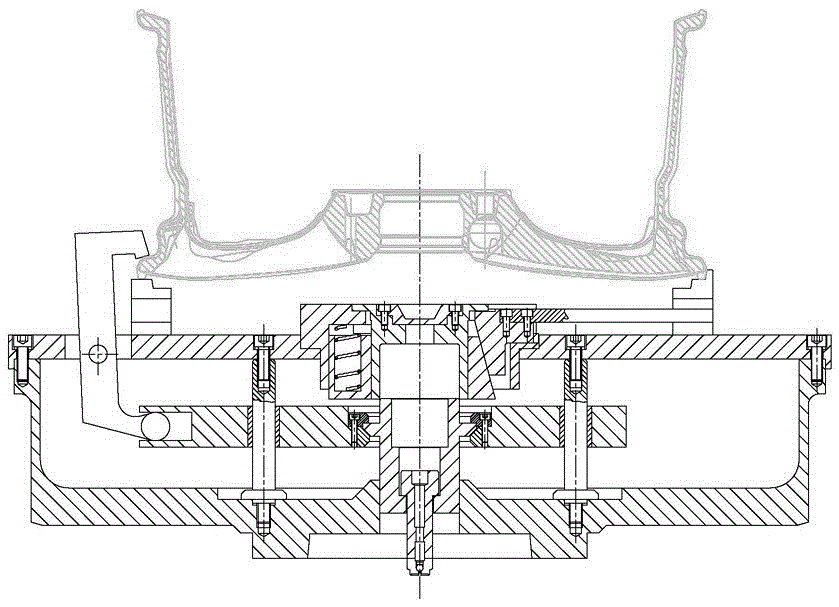

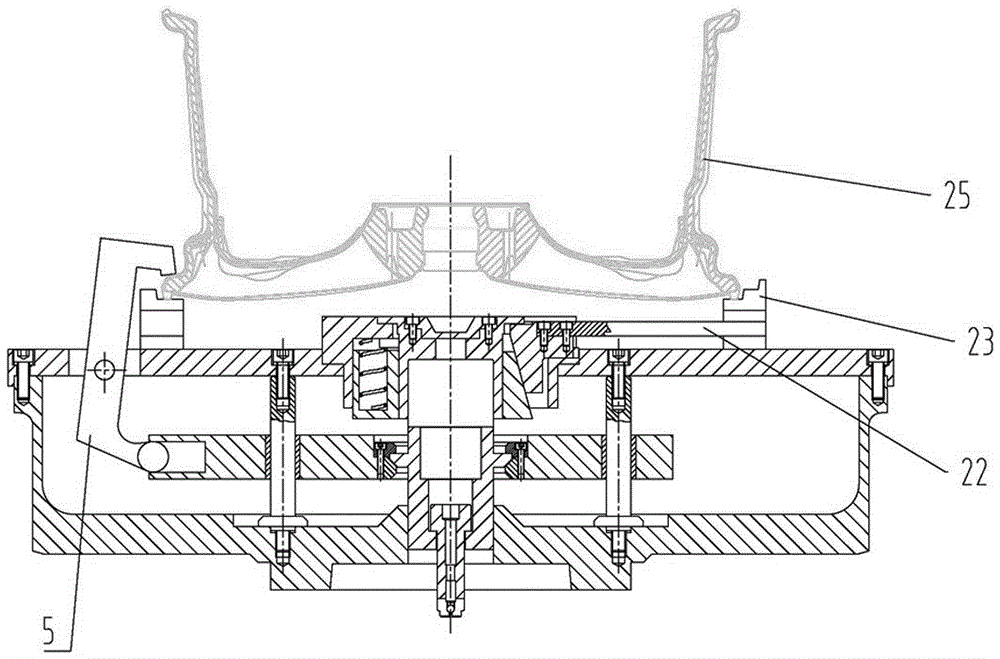

[0021] The details and working conditions of the specific equipment proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] A chuck for an aluminum alloy wheel lathe, comprising an upper cover 1, a chuck body 3, a positioning pin 8, a tension plate 6, an annular pressure plate 14, a pull rod shaft 21, a positioning unit fixing seat 10, a protective cover 20, and a hollow shaft sleeve 19 , Wedge taper sleeve 11, spring 18, slide block 16, transverse tie rod 22, step positioning block 23, crank pressure claw 5, connecting pull stud 13, etc. The upper cover 1 and the chuck body 3 are connected together by screws 2 to form the main body of the chuck. There are mounting holes at the bottom of the chuck main body to install the chuck on the machine tool. The positioning pin 8 is installed on the upper cover 1 and the chuck by screws 9. Between the disc bodies 3, the tie rod shaft 21, the annular pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com