Steel disc for truck and bus tires and tire manufactured by using the same

A technology for trucks and buses and tire treads, which is applied to road vehicle tires, tire treads/tread patterns, tire parts, etc., and can solve the problems of greater impact on vehicle safety, increased braking distance, and greater environmental impact. problems, to achieve the effect of increasing control stability, reducing eccentric wear, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

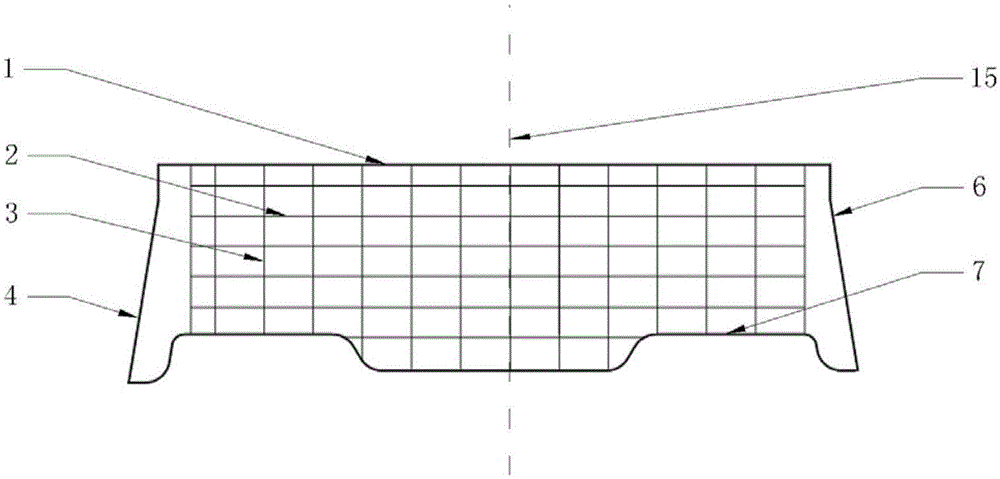

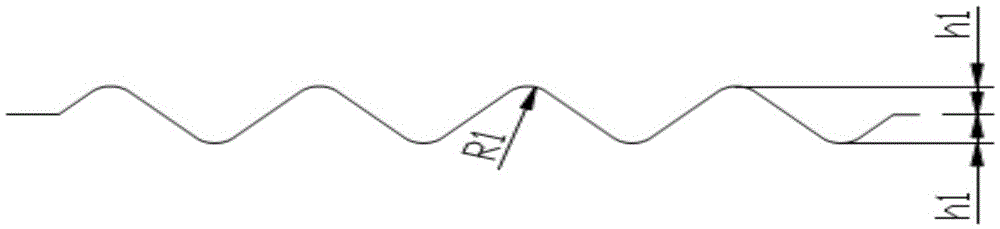

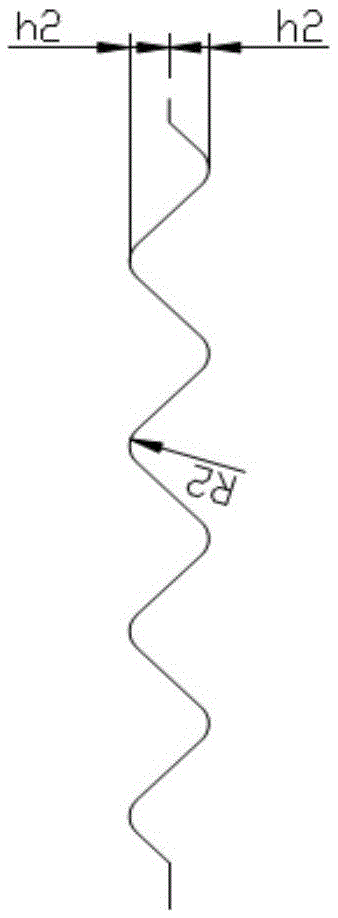

[0032] Such as Figure 1~3 The steel sheet of the truck and bus tire shown is a three-dimensional design as a whole, which is reflected in the three-dimensional space of length, width and thickness; the length and width of the steel sheet are both perpendicular to each other. The dimensions of the waves in the same direction are the same. In the width direction, the wave-shaped surface 2 extends to a position 3mm away from the edge of the steel sheet. In the length direction, the wave-shaped surface 3 is arranged in the middle, accounting for the proportion of the entire length It is 90%, and the two ends are flat design.

[0033] In the length direction of the steel sheet, it is designed to be equal or unequal in length, such as figure 1 As shown in the steel sheet, a short section of the upper part is designed with equal length, and the lower section is designed with unequal length. The straight-line distance between the two ends of the long side II7 is longer than that of...

Embodiment 2

[0037] The steel sheet of Example 1 is fixed on the mold to produce tires with three-dimensional grooves 13 on the tread, and the steel sheet is fixed by placing the pre-processed three-dimensional steel sheet in the corresponding groove on the previously processed mold. In the slot and fixed, the long side I1, wide side I4 and wide side II6 are fixed on the mould. The length of the steel sheet changes with the size of the pattern block, and the width of the steel sheet varies with the depth of the pattern groove, but most of them are 10-18mm. The manufactured tire tread structure is as follows Figure 4 As shown, it includes a central longitudinal groove 11 along the tire tread circumferential direction, side pattern blocks 17 are arranged on both sides of the central longitudinal pattern groove 11, shoulder pattern blocks 16 are arranged outside the side pattern blocks 17, and side pattern blocks 17 The shoulder blocks 16 are separated by side longitudinal grooves 10, the l...

Embodiment 3

[0050] The steel sheet of Example 1 is fixed on the mold to produce tires with three-dimensional grooves 13 on the tread, and the steel sheet is fixed by placing the pre-processed three-dimensional steel sheet in the corresponding groove on the previously processed mold. In the slot and fixed, the long side I1, wide side I4 and wide side II6 are fixed on the mould. The length of the steel sheet changes with the size of the pattern block, and the width of the steel sheet varies with the depth of the pattern groove, but most of them are 10-18mm. The manufactured tire tread structure is as follows Figure 5 As shown, it includes a central longitudinal groove 11 along the circumferential direction of the tire tread, two rows of side pattern blocks 17 are arranged on both sides of the central longitudinal pattern groove 11, and the two rows of side pattern blocks 17 are separated by side longitudinal grooves 10 A shoulder pattern block 16 is arranged on the outer side of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com