Modularized speed-fold chain conveyor belt

A double-speed chain and conveyor belt technology, which is applied in the field of modular double-speed chain conveyor belts, can solve problems such as unstable operation, troublesome tensioning operation, low modularization degree, etc., achieve a high degree of modularization, eliminate safety hazards, and tension The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

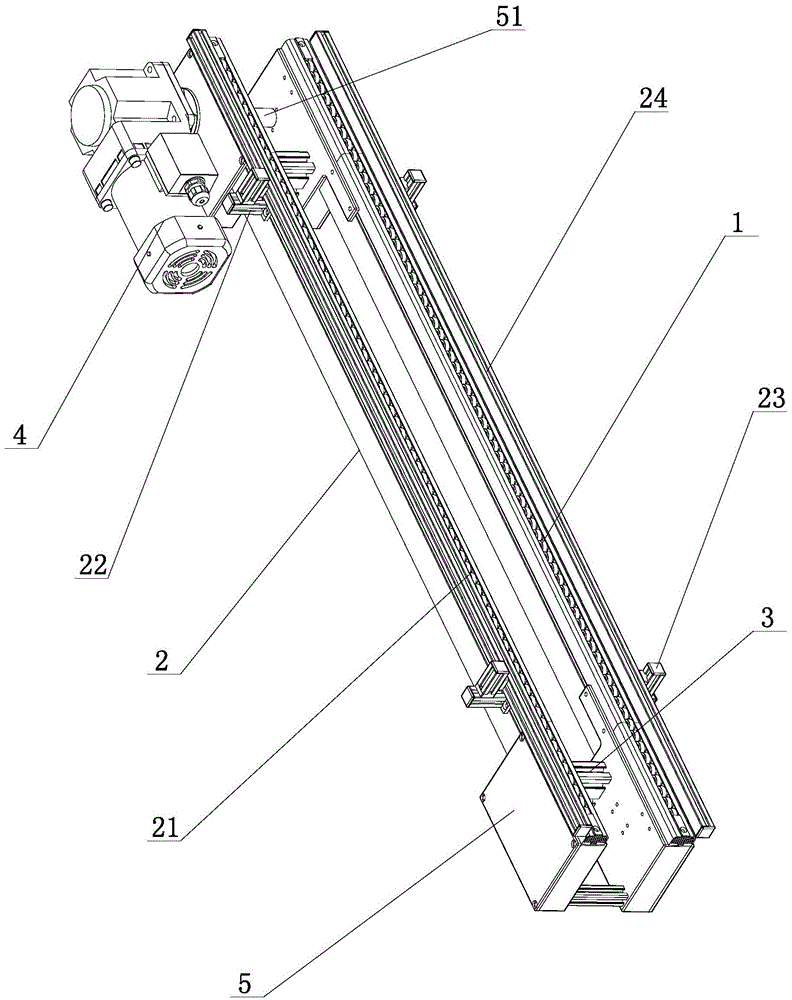

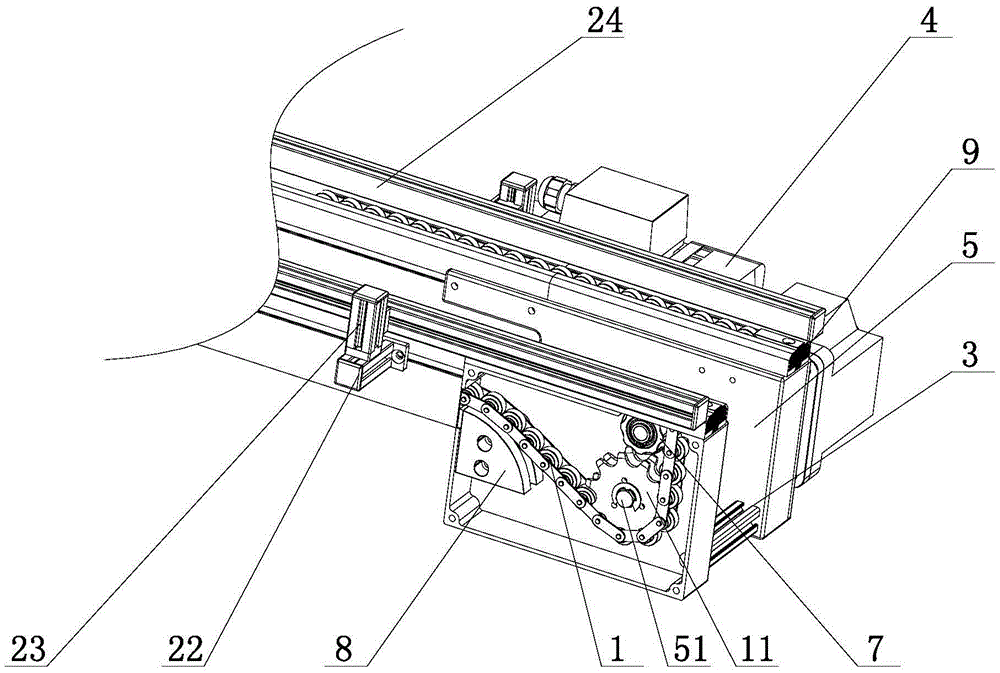

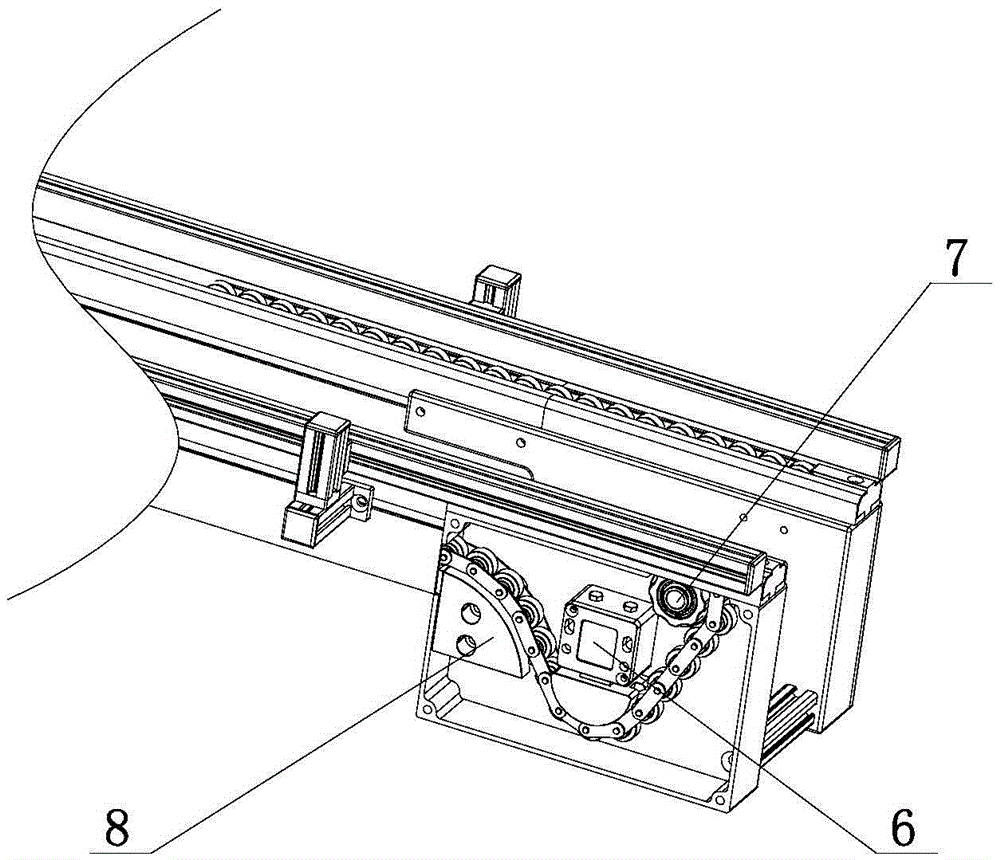

[0032] Such as Figure 1 to Figure 4 As shown, the modular double-speed chain conveyor belt of the present embodiment includes a double-speed chain 1, two side frames 2, a connecting rod 3 and a drive motor 4, and the double-speed chain 1 is arranged in the track 21 of the two side frames 2, and the two-side machine The frame 2 is connected by a connecting rod 3, and the two ends of the frame 2 on both sides are provided with a protective cover 5, and a rotating shaft 51 is arranged in the protective cover 5 at one end, and a protective cover is also arranged outside the rotating shaft, and the sprocket 11 is clamped on the rotating shaft 51, Described sprocket wheel 11 all comprises bearing and gear 111, and gear 111 center offers the axle hole 112 of clamping bearing, and gear 111 is positioned at bearing one side and offers three thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com