Offshore crane hoisting system with rigid telescopic sleeve

A technology of lifting system and telescopic sleeve, which is applied in the field of lifting system of offshore cranes, can solve the problems that the riser does not shake, accurately locate the load, difficult to accurately locate the riser, and complex structure, etc., and achieve the solution of accurate positioning crane load, improve stability and work efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

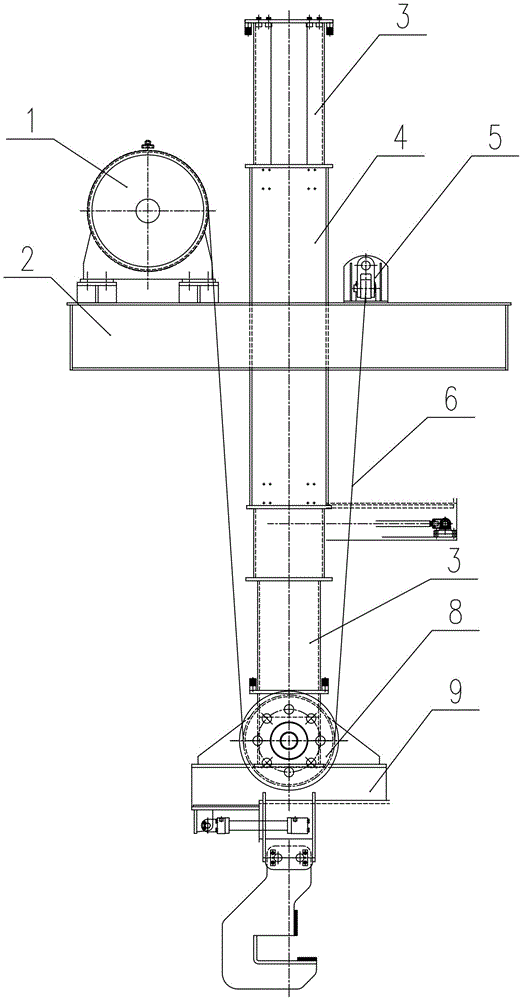

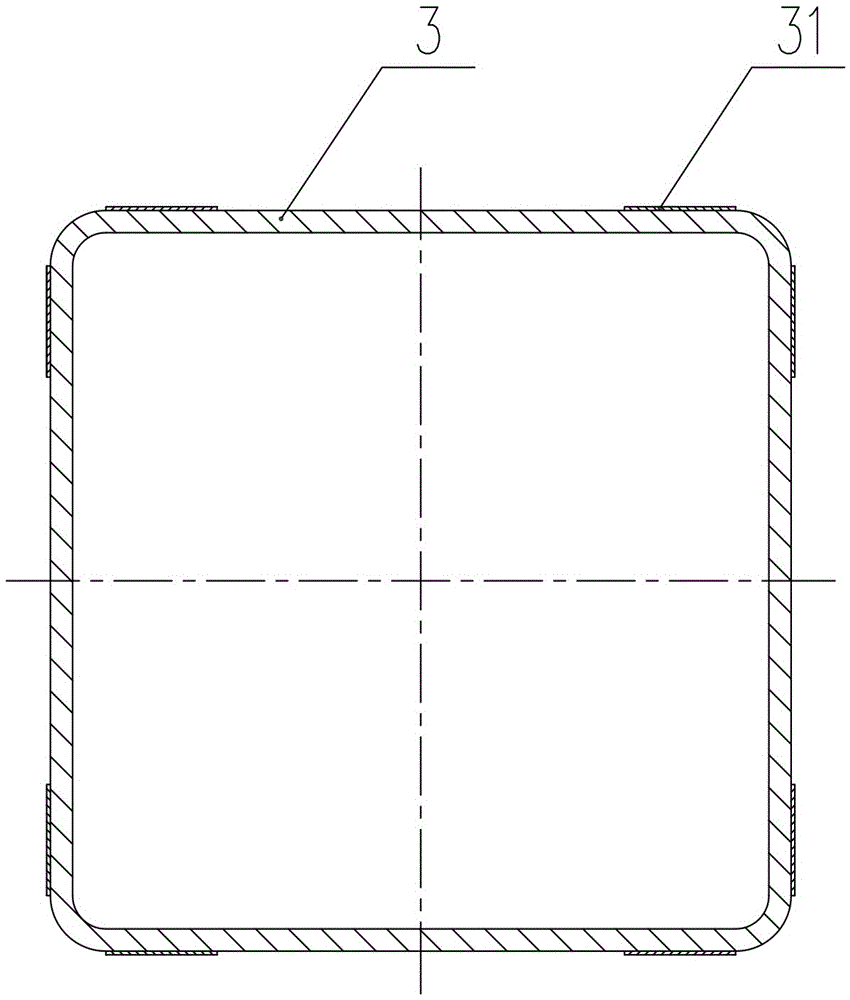

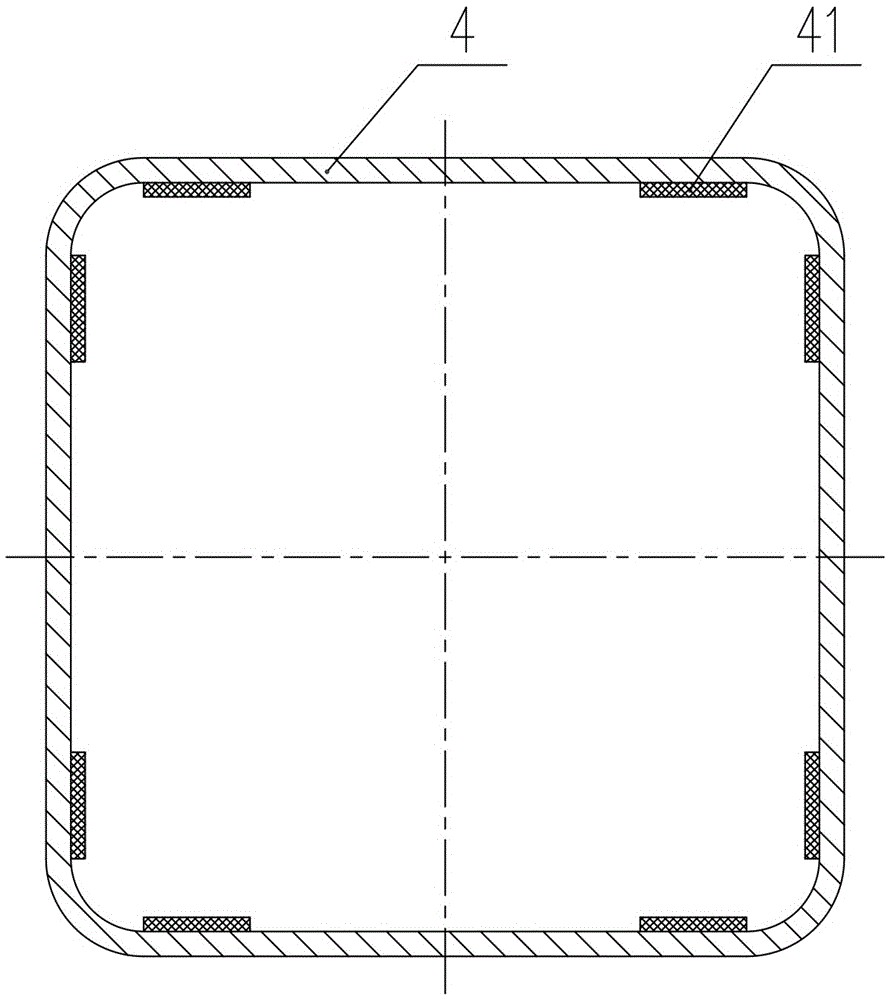

[0014] See attached figure 1 , the present invention consists of a hoisting drum 1 fixedly arranged on a trolley frame 2, a telescopic movable sleeve 3, a rigid fixed sleeve 4, a wire rope fixing device 5, and a hook device 9 provided with a wire rope 6 and a pulley 8. The wire rope 6 is wound on the pulley 8, one end of which is fixed on the lifting drum 1, and the other end is fixed on the wire rope fixing device 5; the rigid fixing sleeve 4 is arranged in the middle of the lifting drum 1 and the wire rope fixing device 5 And it is vertically fixedly connected with the trolley frame 2; the telescopic movable sleeve 3 is set in the rigid fixed sleeve 4 and travels up and down; The top surface of the seat is connected by flanges and bolts; the hook device 9 is welded and fixed on the bottom of the seat of the pulley 8, and the hook device 9 realizes the smooth movement of the hook body up and down through the push-pull action of the telescopic movable sleeve 3; The hook devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com