MEMS (Micro-Electromechanical System) capacitive ultrasonic sensor and manufacturing method thereof

An ultrasonic and capacitive technology, which is used in the measurement of ultrasonic/sonic/infrasonic, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of high parasitic capacitance and high substrate impedance Insulation layer charging and other issues, to achieve the effect of reducing parasitic capacitance, short production cycle, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

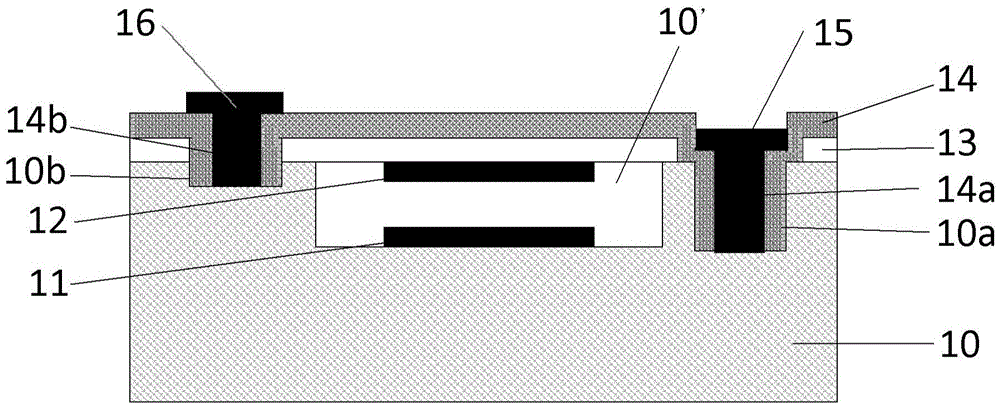

[0028] see figure 1 and figure 2 As shown, the present invention provides a MEMS capacitive ultrasonic sensor, comprising:

[0029] A glass substrate 10, the middle of the glass substrate 10 is a concave cavity 10', grooves 10a, 10b are respectively opened on both sides of the cavity 10', the depth of the groove 10a is the same as that of the cavity The cavity 10' has the same depth, and the groove 10b has the same depth as the lower surface of the upper electrode 12;

[0030] The lower electrode 11 is made at the bottom of the concave cavity 10' of the glass substrate 10;

[0031] A top layer of silicon 13, which is made on the glass substrate 10 and covers the cavity 10', the top layer of silicon 13 is a vibrating membrane, and the thickness of the vibrating membrane is 0.5-10 μm;

[0032] An upper electrode 12, which is made on the lower surface of the top layer of silicon 13, and is positioned above the cavity 10', corresponding to the lower electrode 11;

[0033] A p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com