Natural base-modified light-cured resin eco-friendly manufacturing device

A light-curing resin and manufacturing equipment technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as high pollution and high energy consumption, reduce production costs, reduce energy waste, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

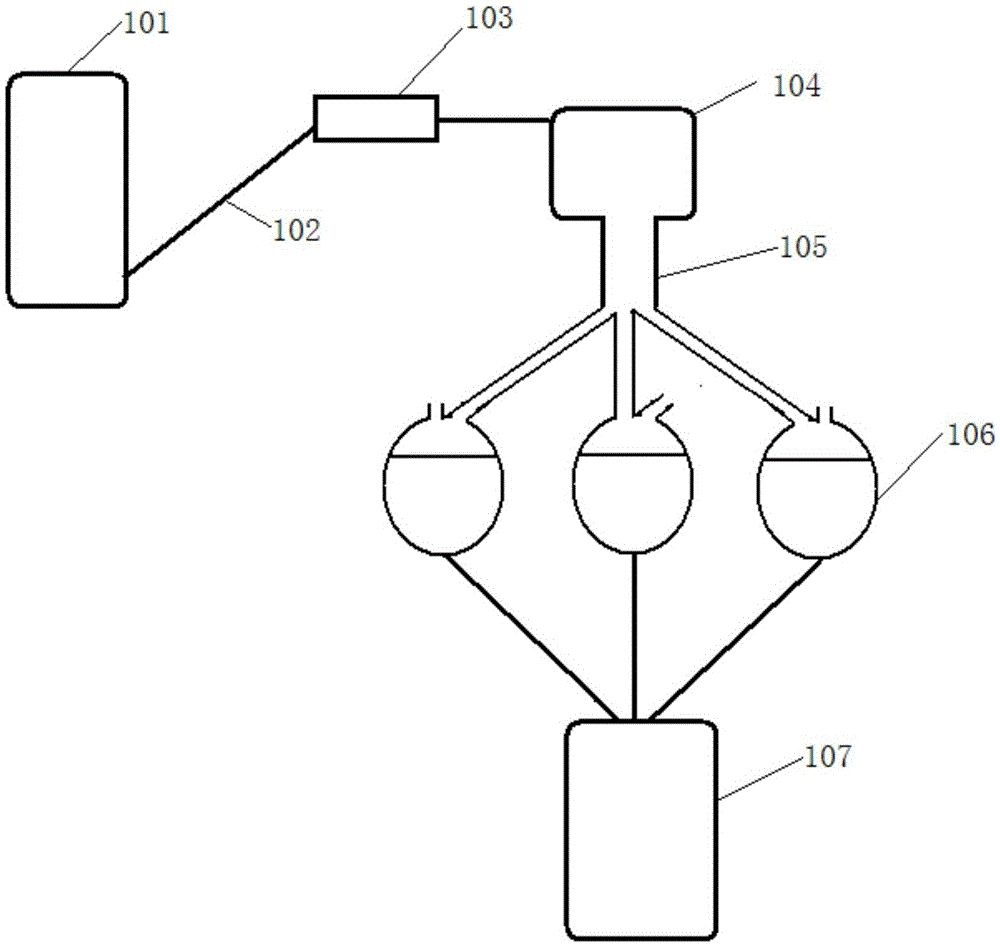

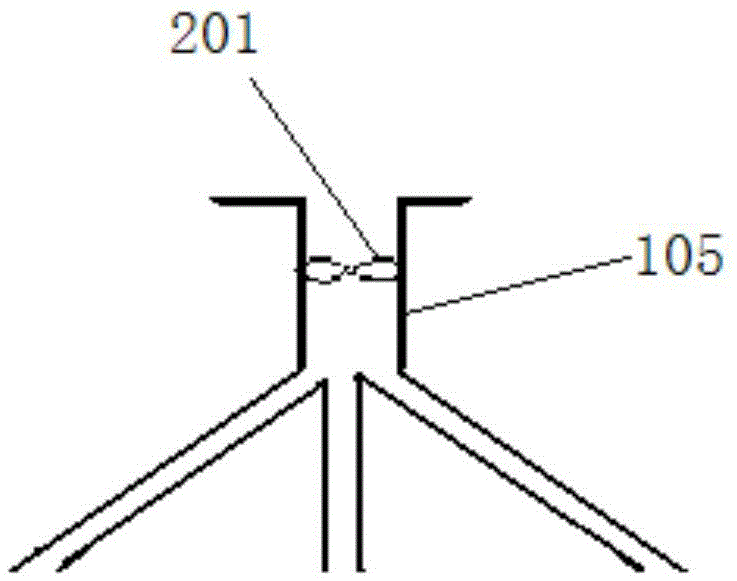

[0030] Refer to figure 1 As shown, an environmentally friendly manufacturing equipment for natural-based modified light-curing resins includes: a raw material warehouse 101, a raw material conveyor belt 102, a decoloring device 103, N three-channel container devices 106, a finished product warehouse 107, and also includes: a waste heat warehouse 104 And waste heat recovery device 105;

[0031] As an example, the number of N is an integer not less than 1;

[0032] As an example, the natural base is vegetable oil, such as one or a combination of linseed oil and soybean oil;

[0033] The raw material storage 101 is connected to one end of the raw material conveyor belt 102, the other end of the raw material conveyor belt 102 is connected to one end of the decolorizing device 103, and the other end of the decolorizing device 103 is connected to the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com