An Improved Delayed Coking Process

A delayed coking and process technology, which is applied in the field of improved delayed coking process, can solve the problems of insufficient effect of increasing liquid recovery, increase of coke and gas yield, and difficult operation of coking unit, so as to reduce coke powder content and reduce oil and gas load , the effect of reducing reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The outlet temperature of the heating furnace 101 , circulation ratio and coke generation period of the embodiment of the present invention and the comparative example are consistent with those of the comparative example.

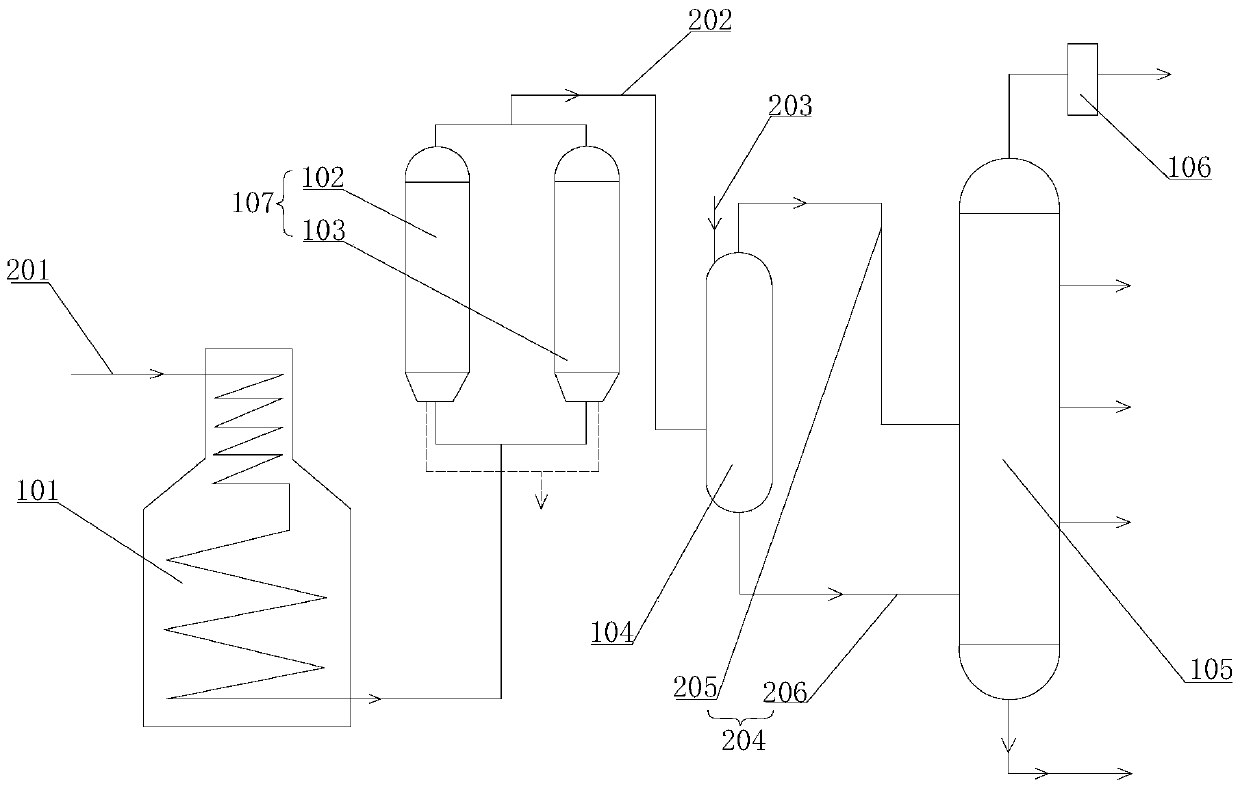

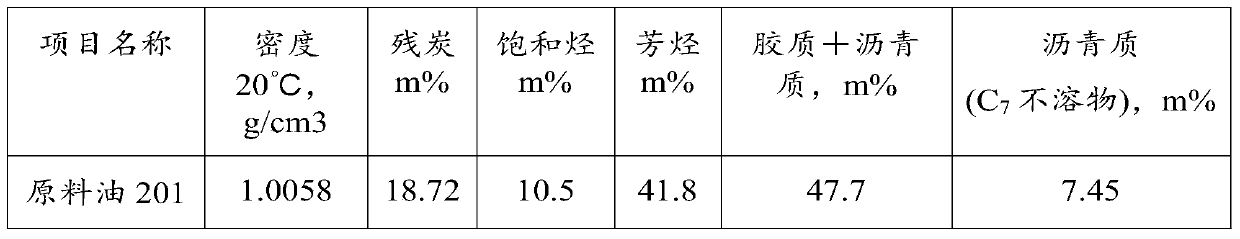

[0045] The steps of the improved delayed coking process mainly include: the raw material oil 201 is heated by the heating furnace 101 to a coking temperature of 498°C, and then enters the first coke tower 102 for coking reaction, the second coke tower 103 is to be produced, and the top of the first coke tower 102 The absolute pressure in the oil-gas buffer tank 104 is 120Kpa. The raw material oil 201 undergoes coking reaction in the first coke tower 102, and the oil gas 202 generated after the reaction enters the oil-gas buffer tank 104 through the oil transfer line. The absolute pressure in the oil-gas buffer tank 104 is 102Kpa. The cooling medium 203 is passed into the tank 104. In this embodiment, the cooling medium 203 is preferably coked diesel o...

Embodiment 2

[0048] The steps of the improved delayed coking process mainly include: the raw material oil 201 is heated by the heating furnace 101 to a coking temperature of 498°C, and then enters the first coke tower 102 for coking reaction, the second coke tower 103 is to be produced, and the top of the first coke tower 102 The absolute pressure in the oil-gas buffer tank 104 is 150Kpa. The raw material oil 201 undergoes coking reaction in the first coke tower 102, and the oil gas 202 generated after the reaction enters the oil-gas buffer tank 104 through the oil transfer line. The absolute pressure in the oil-gas buffer tank 104 is 133Kpa. Pass into cooling medium 203 in the tank, preferably cooling medium 203 is coking wax oil in the present embodiment, the temperature of coking wax oil is 120 ℃, and the amount of coking wax oil accounts for 15% of the mass percent of raw material oil 201, and coking wax oil is to The generated oil gas 202 entering the oil-gas buffer tank 104 is cooled,...

Embodiment 3

[0051] The steps of the improved delayed coking process mainly include: the raw material oil 201 is heated by the heating furnace 101 to a coking temperature of 498°C, and then enters the first coke tower 102 for coking reaction, the second coke tower 103 is to be produced, and the top of the first coke tower 102 The absolute pressure in the oil-gas buffer tank 104 is 170Kpa. The raw material oil 201 undergoes coking reaction in the first coke tower 102, and the oil gas 202 generated after the reaction enters the oil-gas buffer tank 104 through the oil transfer line. The absolute pressure in the oil-gas buffer tank 104 is 152Kpa. The cooling medium 203 is passed into the pipe. In this embodiment, the cooling medium 203 is preferably a mixture of coker gasoline, coker diesel oil and coker wax oil. The temperature of the mixture is 110° C., and the amount of coker wax oil accounts for 19% of the mass percentage of the raw material oil 201. , the mixture cools the generated oil ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com