Steel arc distributive girder structure of rod type bracket for cast-in-place arch bridge and construction method

A cast-in-place arch bridge and distribution beam technology, applied in the direction of bridges, arch bridges, bridge forms, etc., can solve the problems of deviation in the determination of wood specifications, lack of scientific rigor, improper handling of joints, etc., to prevent eccentric side bending damage and connection. The effect of firmness and reliability, strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

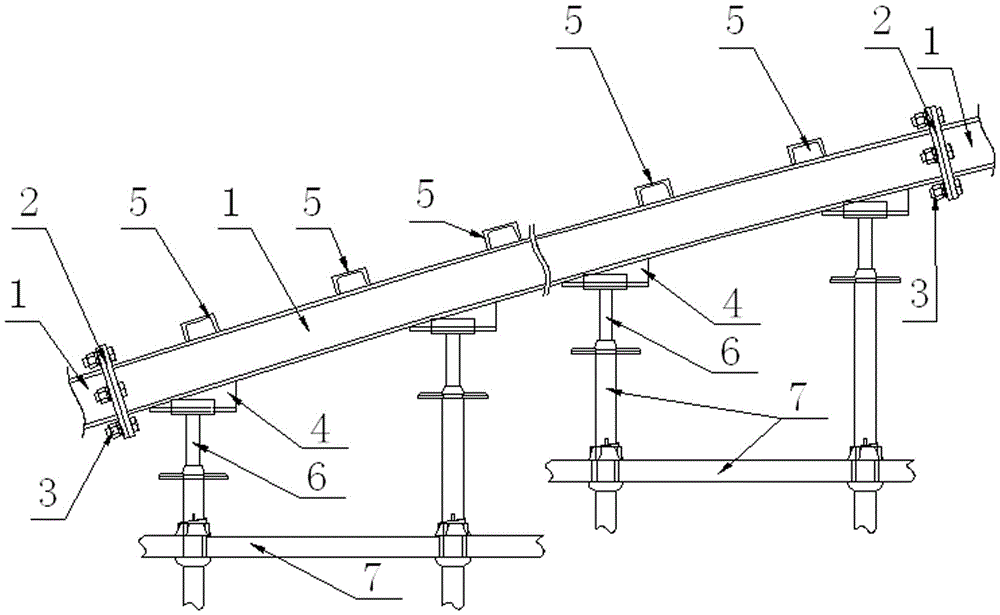

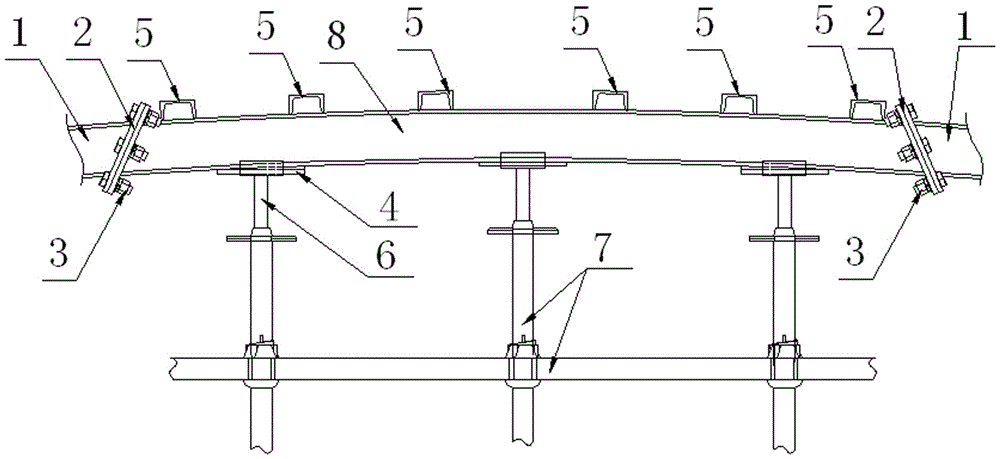

[0041] see figure 1 , 2, 3, 4, a kind of cast-in-place arch bridge bar support steel arc-shaped distribution beam structure of the present invention, described structure replaces the wooden arch beam structure in the cast-in-place arch bridge, and supports the construction of the whole arch bridge; the structure consists of Several sections of arc-shaped distribution beams 1 are connected, and a wedge-shaped seat 4 is provided under the arc-shaped distribution beam 1, which is placed on the adjustable jacking 6 on the top of the pole-type full hall support 7; an anti-skid block is arranged above the arc-shaped distribution beam 1 5. Prevent the upper lateral distribution beam from sliding.

[0042] Said construction is made of steel material.

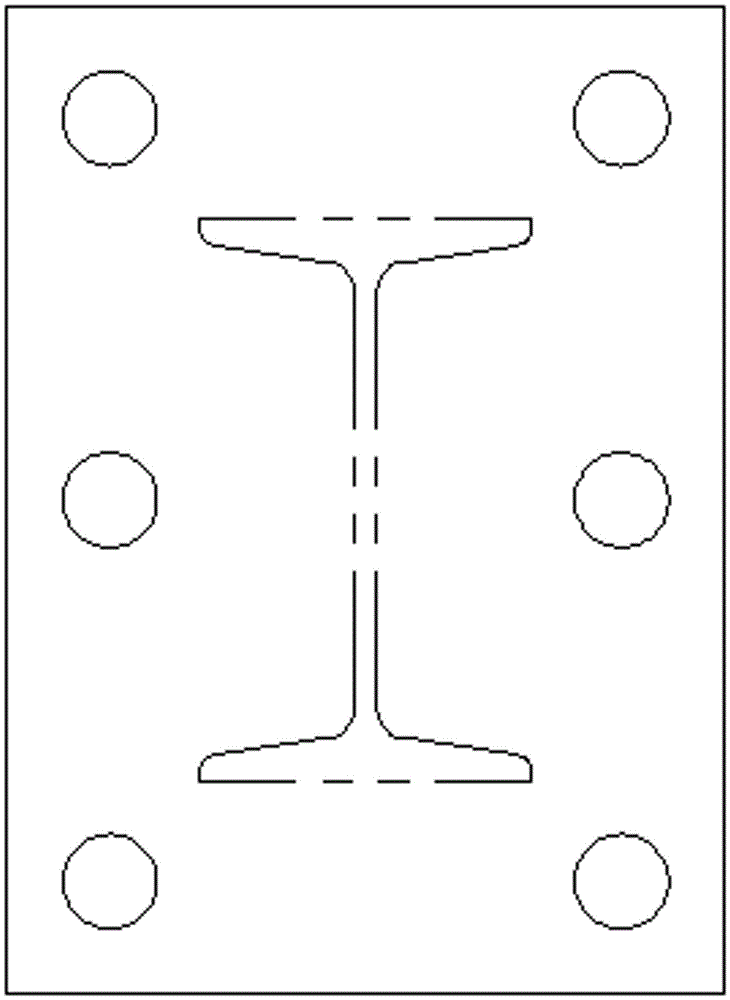

[0043] The curved distribution beam 1 is formed by bending I-shaped steel.

[0044] Flanges 2 are installed at both ends of the arc-shaped distribution beam 1 , through which the sections of the arc-shaped distribution beam 1 are butt...

Embodiment 2

[0061] see figure 1 , 2, 3, 4, a kind of cast-in-place arch bridge bar support steel arc-shaped distribution beam structure of the present invention, described structure replaces the wooden arch beam structure in the cast-in-place arch bridge, and supports the construction of the whole arch bridge; the structure consists of Several sections of arc-shaped distribution beams 1 are connected, and a wedge-shaped seat 4 is provided under the arc-shaped distribution beam 1, which is placed on the adjustable jacking 6 on the top of the pole-type full hall support 7; an anti-skid block is arranged above the arc-shaped distribution beam 1 5. Prevent the upper lateral distribution beam from sliding.

[0062] Said construction is made of steel material.

[0063] The curved distribution beam 1 is formed by bending H-shaped steel.

[0064] Flanges 2 are installed at both ends of the arc-shaped distribution beam 1 , through which the sections of the arc-shaped distribution beam 1 are butt...

Embodiment 3

[0081] see figure 1 , 2, 3, 4, a kind of cast-in-place arch bridge bar support steel arc-shaped distribution beam structure of the present invention, described structure replaces the wooden arch beam structure in the cast-in-place arch bridge, and supports the construction of the whole arch bridge; the structure consists of Several sections of arc-shaped distribution beams 1 are connected, and a wedge-shaped seat 4 is provided under the arc-shaped distribution beam 1, which is placed on the adjustable jacking 6 on the top of the pole-type full hall support 7; an anti-skid block is arranged above the arc-shaped distribution beam 1 5. Prevent the upper lateral distribution beam from sliding.

[0082] Said construction is made of steel material.

[0083] The curved distribution beam 1 is formed by bending channel steel.

[0084] Flanges 2 are installed at both ends of the arc-shaped distribution beam 1 , through which the sections of the arc-shaped distribution beam 1 are butte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com