Steel fiber regeneration brick granule concrete single-rib baseboard composite floor slab and manufacturing method thereof

A technology of superimposed floor slabs and recycled bricks, which is applied to floors, building structures, building components, etc., can solve the problems of low bearing capacity and poor seismic performance of superimposed floor slabs, and achieves good integrity, resource saving, and superior seismic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

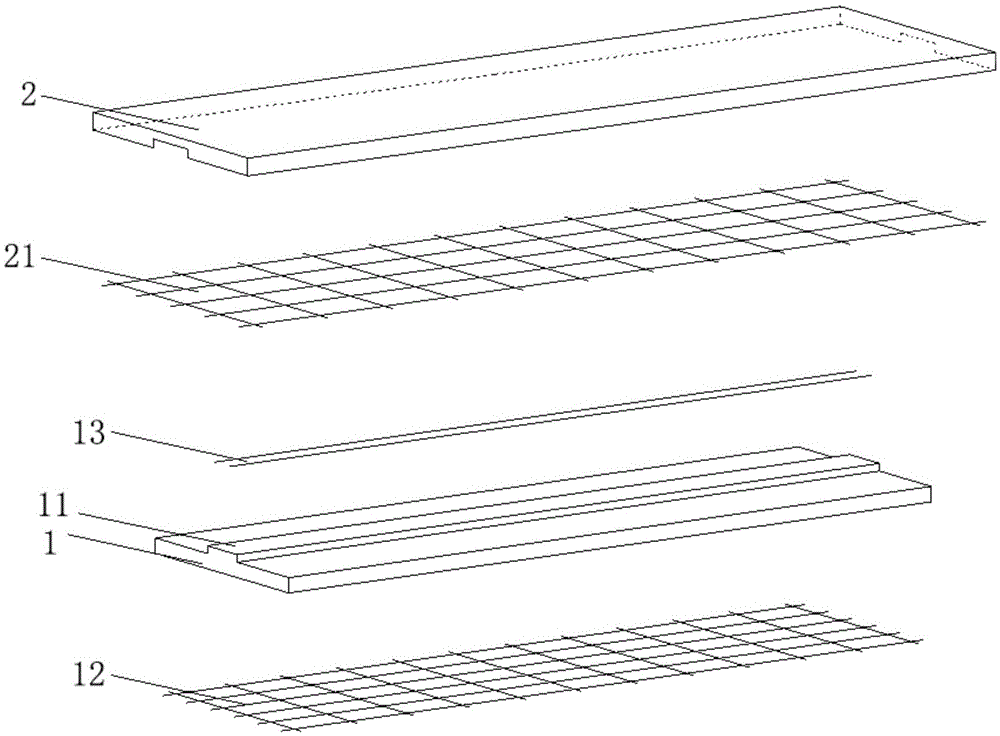

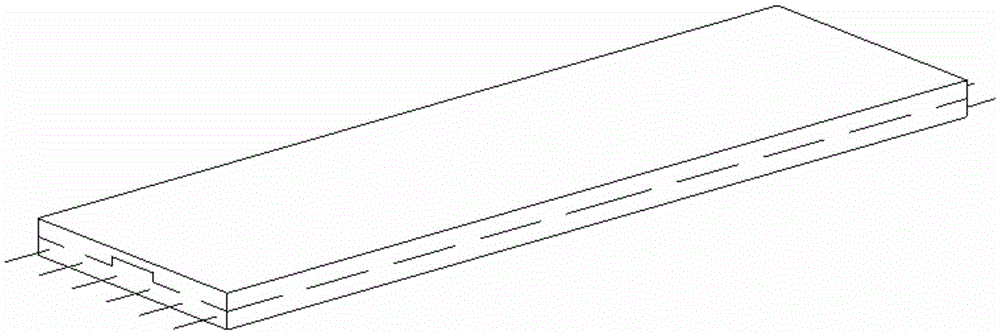

[0023] like figure 1 and figure 2 As shown, a steel fiber regenerated brick concrete single-rib floor composite floor includes a steel fiber recycled brick concrete prefabricated floor 1 with a single rib 11, and a steel fiber recycled brick concrete prefabricated floor 1 has a single rib 11 There is cast-in-place concrete layer 2 on one side, forming a state of bite.

[0024] The steel fiber regenerated brick concrete prefabricated floor 1 of the present invention adopts steel fiber regenerated brick concrete, and the steel fiber regenerated brick concrete is a new type of ecological material, which has light weight, thermal insulation, good fire resistance, good corrosion resistance, Good seismic performance and other characteristics. The ratio of steel fiber recycled brick concrete is:

[0025] Each cubic meter of concrete contains 78kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com