Formwork strip paving construction method, combined split formwork and formwork quick-release joints

A combined, formwork technology, applied in the connection of formwork/formwork/work frame, formwork/formwork/work frame, on-site preparation of building components, etc., can solve the cumbersome demolition process, long construction period, Problems such as poor molding quality, to achieve the effect of ensuring rigidity, speeding up the number of turns, and speeding up the turnaround cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

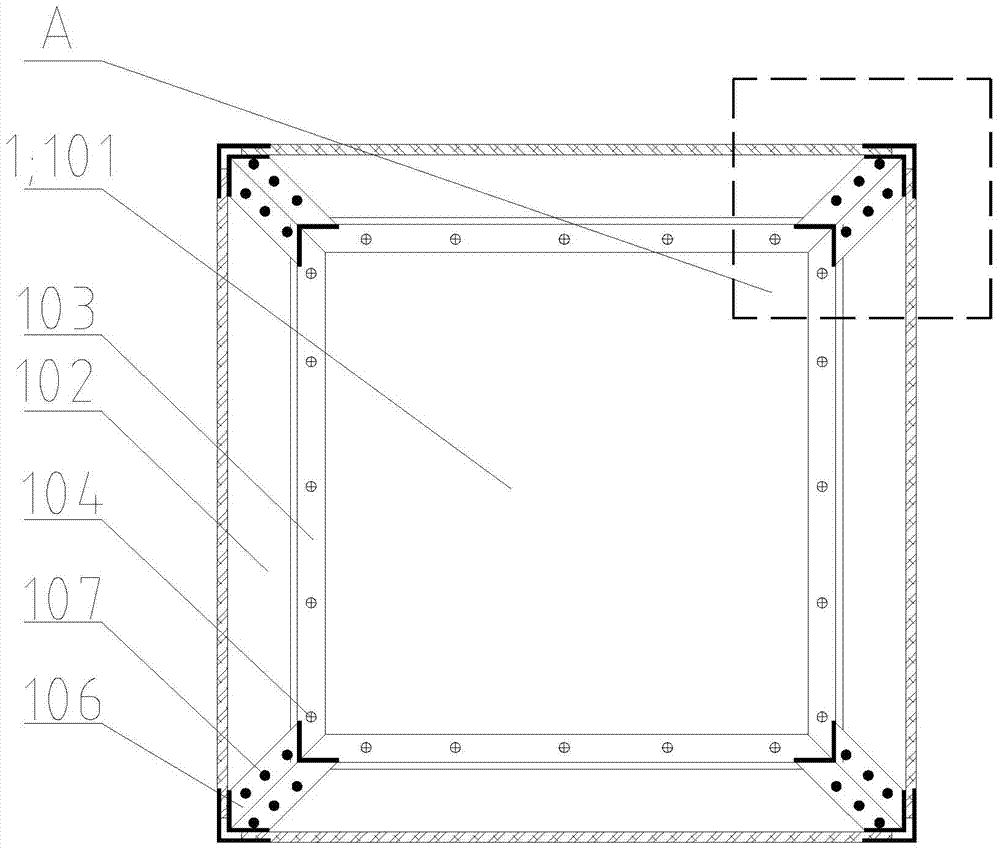

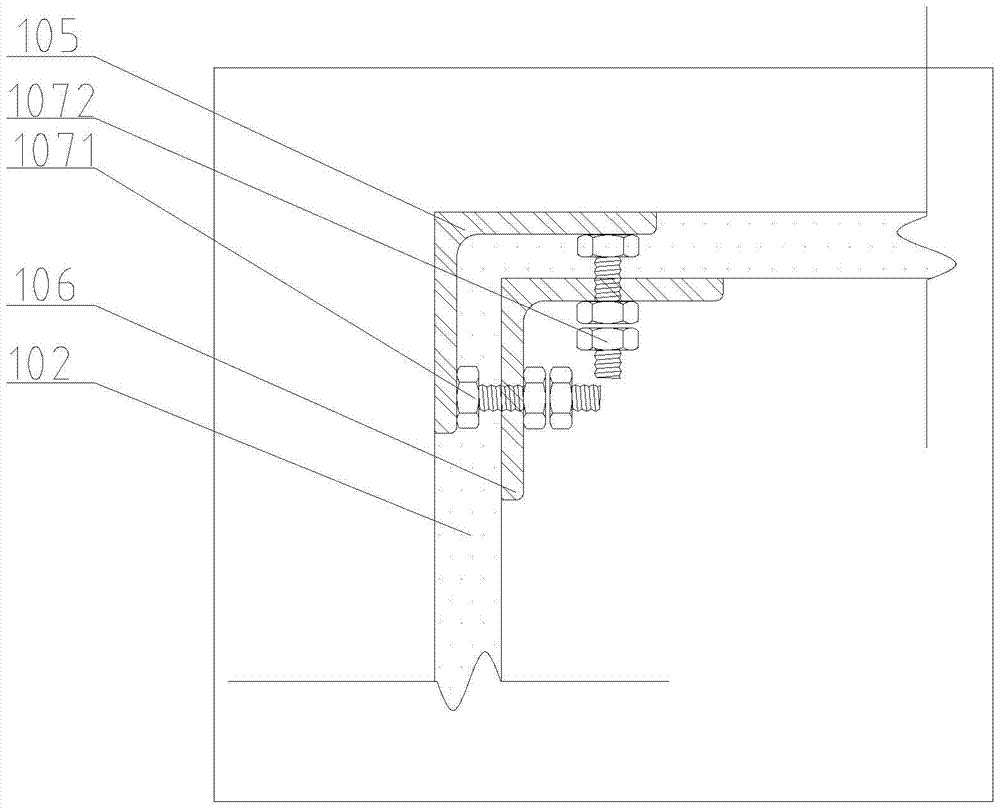

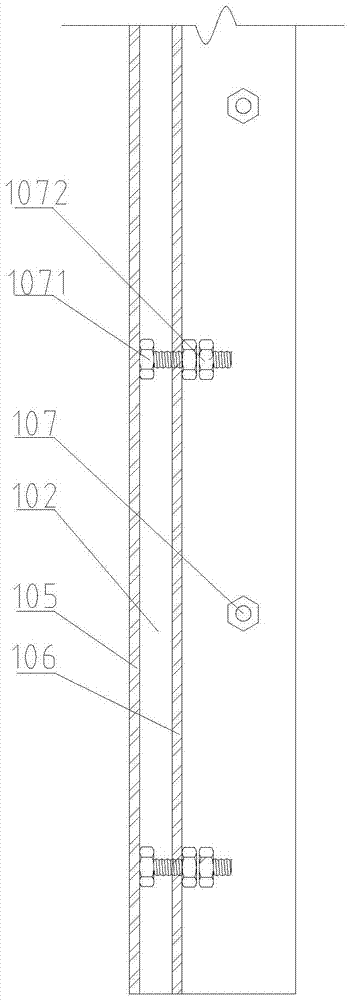

[0043] The invention discloses a combined split formwork, see Figure 1-Figure 3 , the split formwork 1 has an inverted conical structure with an open upper end as a whole, the split formwork 1 includes a bottom mold 101 and a side mold 102, the bottom mold 101 is placed horizontally, and the side mold 102 is assembled by a detachable inner liner 103 Around the bottom mold 101, the inner lining plate 103 adopts 50mm*50mm*4mm galvanized angle steel, and the two right angle sides of the galvanized angle steel are fixed with the side mold 102 and the bottom mold 101 by self-tapping screws 104, and the inner lining plate 103 is made of Galvanized angle steel ensures the lateral rigidity and longitudinal rigidity of the split formwork.

[0044] Adjacent side molds 102 are connected by a split structure, figure 2 It is a schematic diagram of the dismantling structure. The dismantling structure includes an external dismantling structure 105, an internal dismantling structure 106 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com