Support structure for inner cylinder of chimney

A technology of support structure and inner cylinder, applied in the field of support structure of the chimney inner cylinder, can solve the problems of large steel consumption, many connection nodes, unfavorable operation and maintenance, etc., achieve low steel consumption, enhance overall stability, and bear powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below:

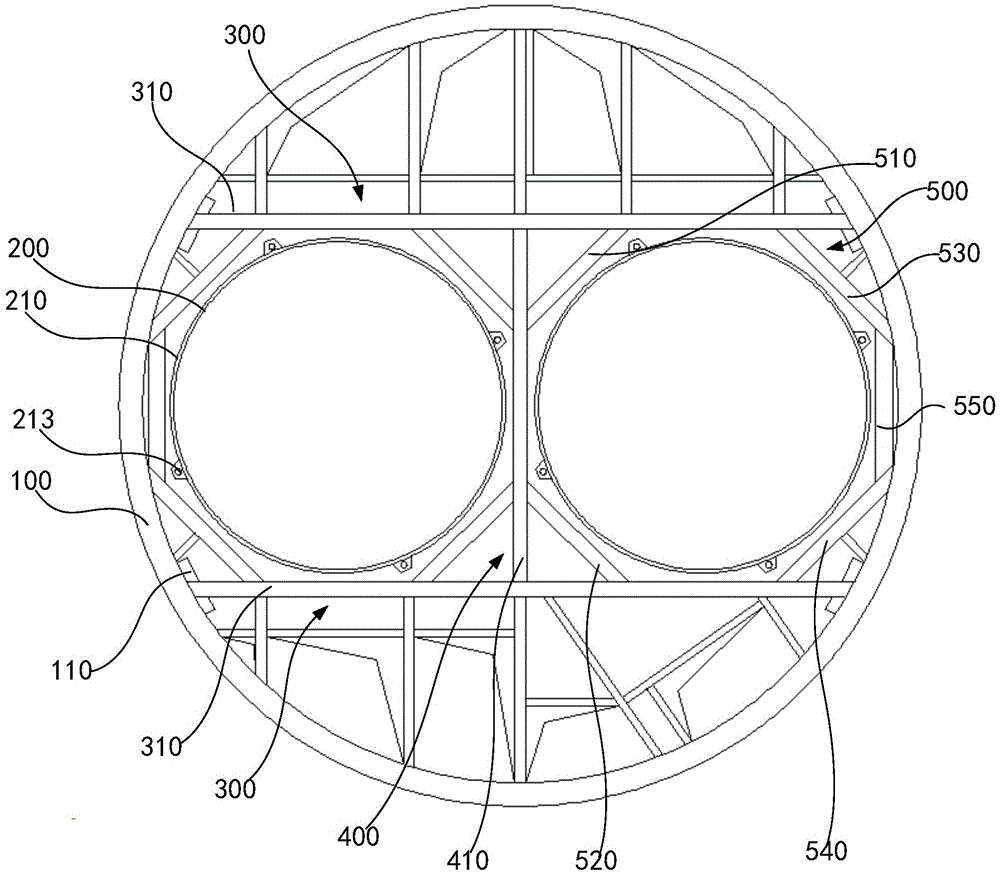

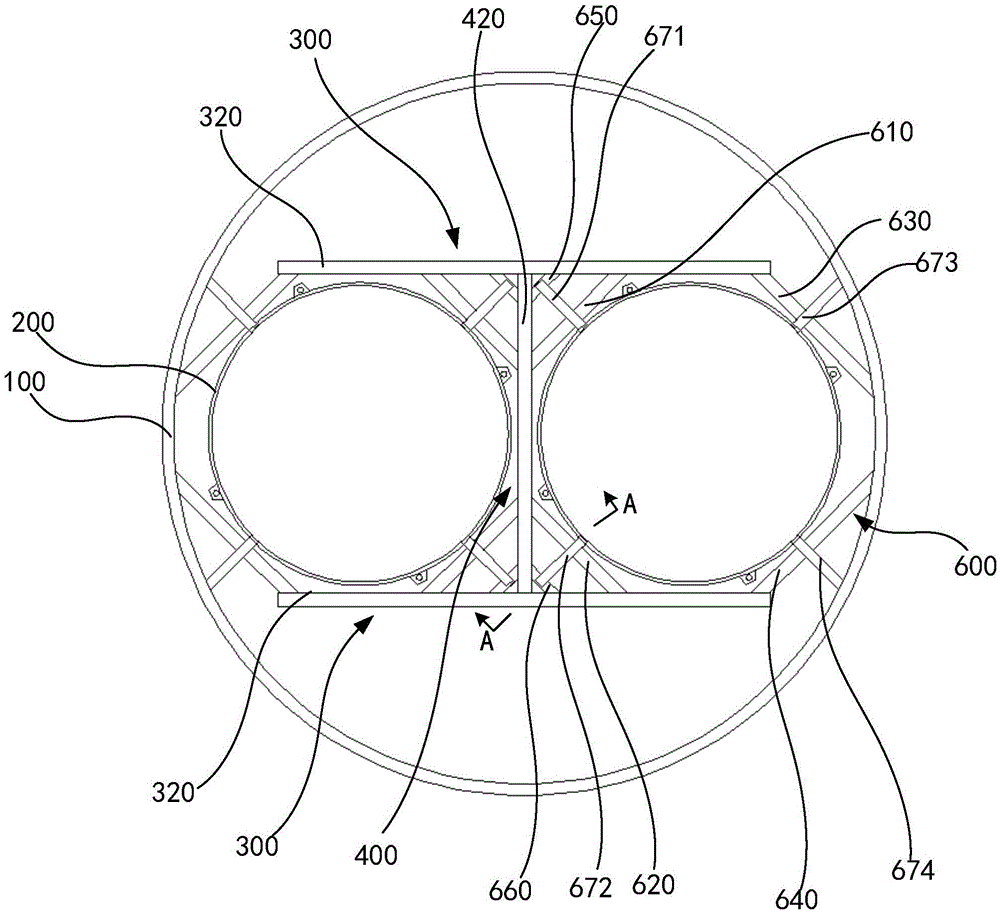

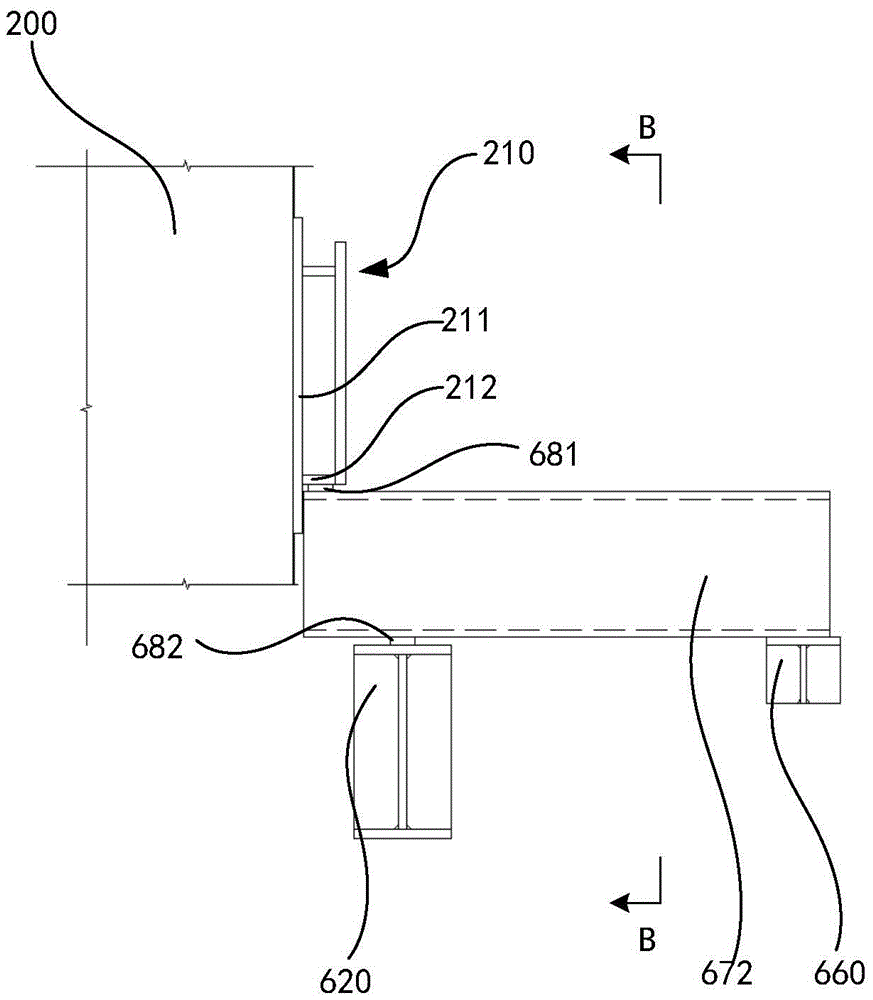

[0034] The chimney includes an outer cylinder 100 and at least one inner cylinder 200 suspended in the outer cylinder 100 . The outer cylinder 100 is a concrete outer cylinder 100 , and the inner cylinder 200 is a steel inner cylinder 200 . Such as Figure 1-2 As shown, a support structure for an inner cylinder of a chimney includes two first trusses 300 located in the outer cylinder 100 and oppositely arranged. Both first trusses 300 include a first upper chord 310, a first lower chord 320 and a first web 330 between the first upper chord 310 and the first lower chord 320, as Figure 5 shown. The inner wall of the outer cylinder 100 is provided with four corbels 110 , and one end of each first upper chord 310 is supported and fixed on one of the corbels 110 . The length of the first upper chord 310 is greater than that of the first lower chord 320 , which facilitates the installation of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com