Special thread direct connection type large diameter oil pipe sleeve

A special thread and direct connection technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of unreasonable thread design, inconvenient maintenance, and slow thread connection speed, so as to improve the screwing speed and screwing speed. The effect of strength, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

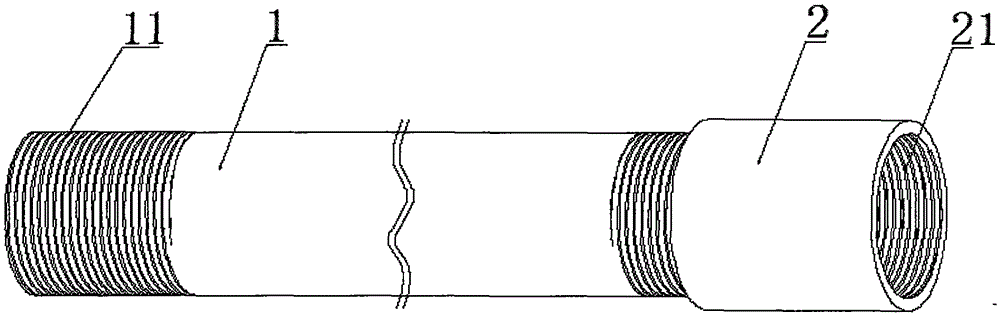

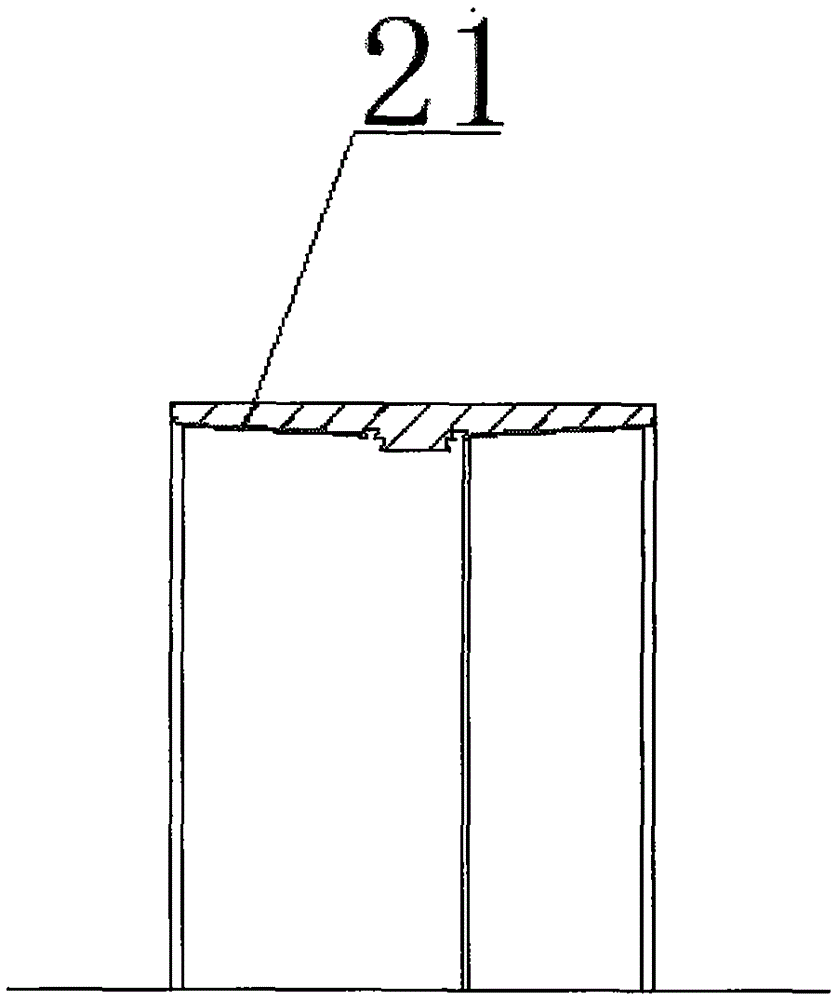

[0015] The present invention will be further described below in conjunction with the accompanying drawings. As shown in the accompanying drawings, taking the RT-TS-3 special thread developed by our company as an example to further introduce the present invention, the present invention consists of two parts, which are the oil delivery pipe 1 and the oil pipe connection sleeve 2 respectively. The oil delivery pipe 1 The two ends of the oil pipe are processed with threads; the inner two ends of the oil pipe connecting sleeve 2 are processed with threads that are connected with the oil delivery pipe 1.

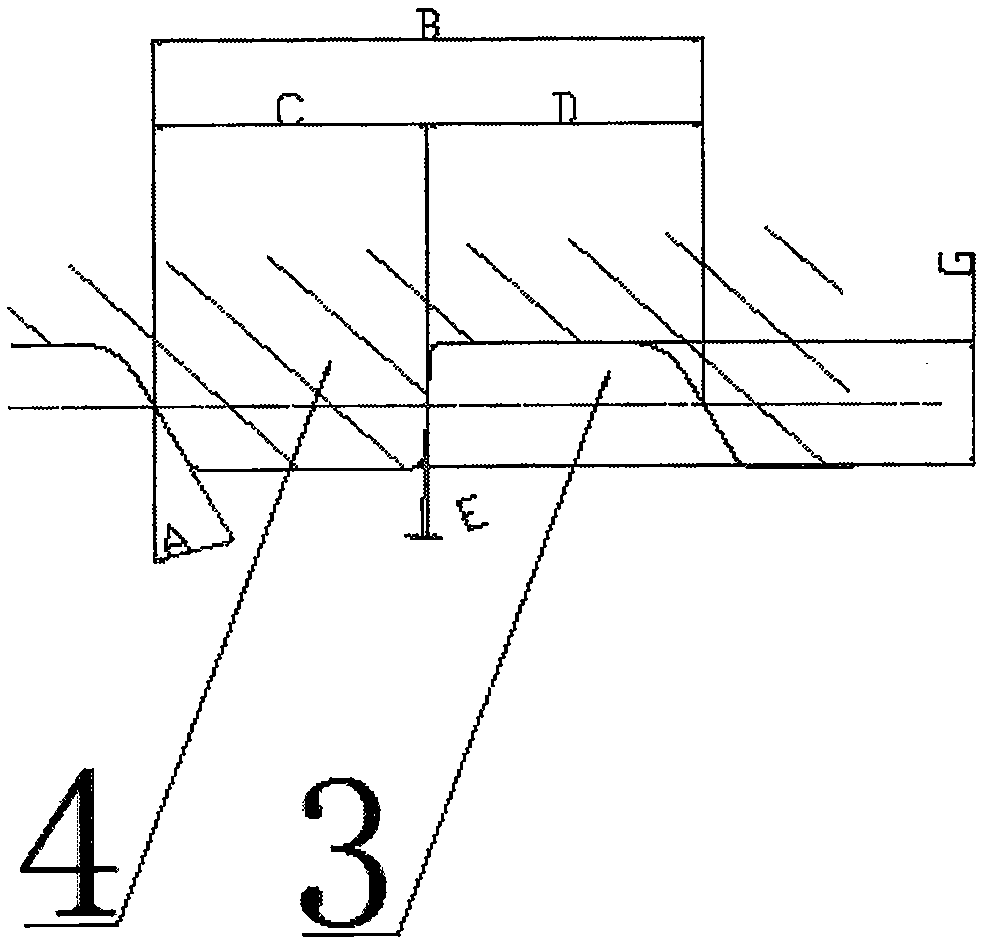

[0016] The oil pipe connection sleeve 2 is an internal thread 21, and the two ends of the oil delivery pipe 1 are processed with an external thread 11 matching the internal thread 21 of the oil pipe connection sleeve 2. The thread can be a double thread or a three thread, such as As shown in the accompanying drawings, the length B of each pitch cycle of the internal thread is 8.46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com