Automobile magnetic and frictional compound brake based on magnetic and frictional coupling effect

A technology of coupling effect and compound braking, which is applied in the direction of brake type, axial brake, gear transmission mechanism, etc., can solve the problems of complex mechanical structure, no braking parameter monitoring and feedback adjustment, and real-time monitoring of few important parameters. , to achieve the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

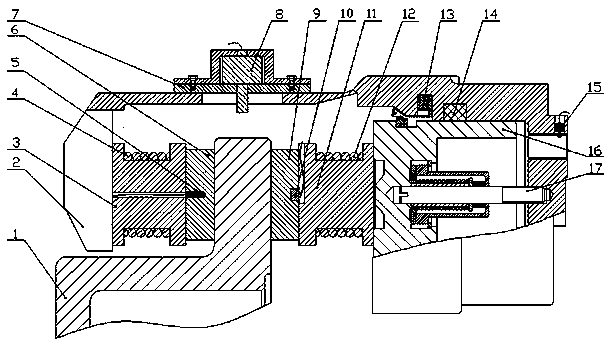

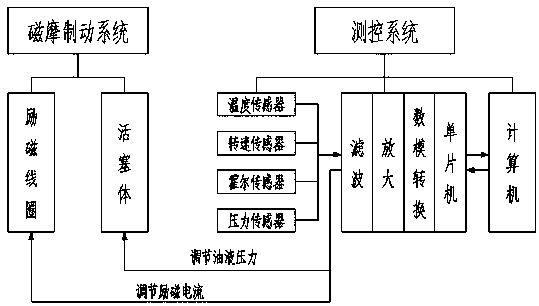

[0020] Such as figure 1 As shown, the automobile magnetic friction composite brake based on the magnetic friction coupling effect includes a magnetic friction braking system and a measurement and control system, and the measurement and control system includes sensors and computers;

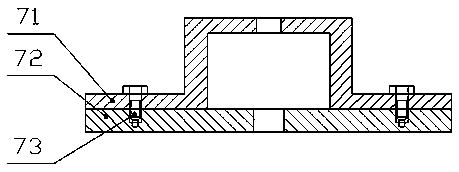

[0021] The magnetic friction braking system includes a brake disc 1, a brake caliper 2, a left back plate 3, a left friction plate 6, a sensor carrier 7, a right friction plate 9, a right back plate 11, a piston cover 13 and a piston 16,

[0022] The left backboard 3 and the right backboard 11 have grooves along the circumferential surface. The backboard is in the shape of "I", and the left excitation coil 4 and the right excitation coil 12 are respectively wound in the grooves of the left backboard 3 and right backboard 11. Among them, the left back plate 3 has through holes from the left sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com