A Method of Pneumatic Separation of Bullet Holder by Muzzle Cutter

A pneumatic separation and cutter technology, which is applied in ammunition testing, ammunition, weapon accessories, etc., can solve the problems of projectile speed influence, easy mutual interference, and inability to closely cooperate with the overall seal, so as to ensure stability, ensure tight fit and Hermeticity, the effect of eliminating mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

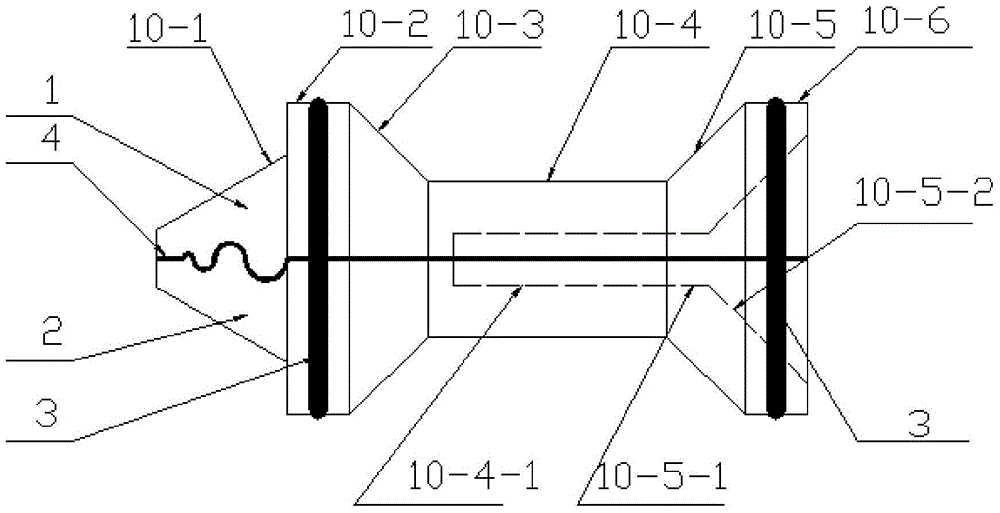

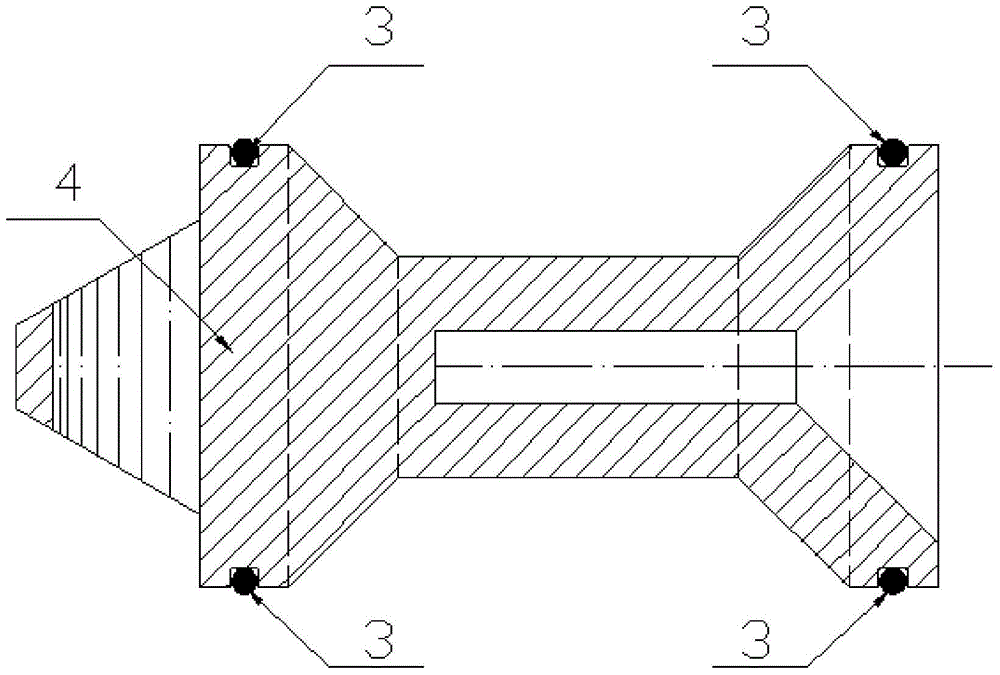

[0019] Specific implementation mode one: combine Figure 1 to Figure 5 Illustrate this embodiment, a kind of method that realizes the aerodynamic separation of bullet holder by muzzle cutter, it comprises the following steps:

[0020] Step 1: Installation of cutter and bullet holder:

[0021] The upper lobe 1 and the lower lobe 2 are cut from the same rotator along the symmetrical plane, and multiple muzzle cutters 6 are installed on the outer surface of the gun bore in the direction of the outlet. On the right are the first tapered section 10-1, the first columnar section 10-2, the tapered section 10-3, the second columnar section 10-4, the second tapered section 10-5 and The third columnar section 10-6; the upper lobe 1 and the lower lobe 2 are matched on the first gradually expanding cone section 10-1 by means of involute arc teeth; the upper lobe 1 and the lower lobe 2 are coated with Thin-layer plastic 4; the first columnar section 10-2 and the third columnar section 10...

specific Embodiment approach 2

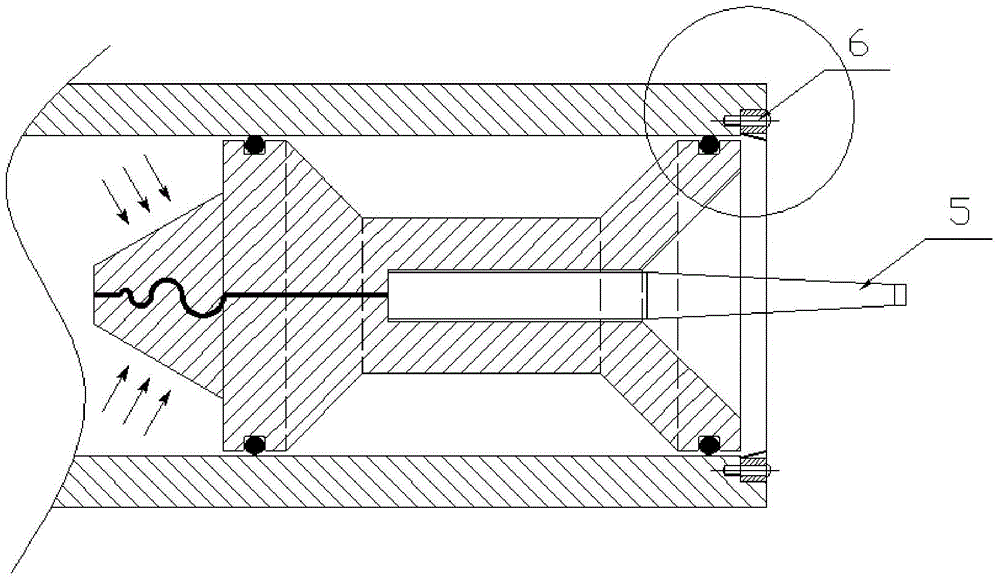

[0026] Specific implementation mode two: combination Figure 3 to Figure 5Describe this embodiment, each muzzle cutter 6 in a plurality of muzzle cutters 6 in step 1 of this embodiment all comprises cutting blade frame 6-1 and cutting blade 6-2, and cutting blade frame 6-1 Installed on the outer wall of the gun bore by bolts, the cutting blade 6-2 is installed on the lower end of the cutting tool holder 6-1, and the lower edge of the cutting blade 6-2 stretches out toward the gun bore inner cavity. When the bullet holder moves forward at high speed, the inner surface of the variable diameter reaming hole 10-5-2 is affected by high-pressure pneumatic force; the two sealing rings 3 on the bullet holder are sequentially split by the muzzle cutter 6 when the bullet is discharged from the bore, as image 3 Shown; Wherein the cutting blade 6-2 lower edge protrudes into the gun bore less than the gap between the bullet holder and the gun chamber, and the cutting blade 6-2 does not co...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 3 to Figure 5 To illustrate this embodiment, the cutting blade 6-2 in Step 1 of this embodiment is a triangular cutting piece, and the cutting edge of the cutting blade 6-2 faces the cavity exit direction of the upper lobe 1 and the lower lobe 2. Such setting is convenient to ensure that the blade faces the sealing ring and cuts the sealing ring just in time. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com