Humidity generation ice surface saturator

A humidity generation and ice surface technology, applied in the field of humidity generation ice surface saturator, can solve the problem of long gas travel path, etc., and achieve the effects of convenient operation, high saturation and high saturation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

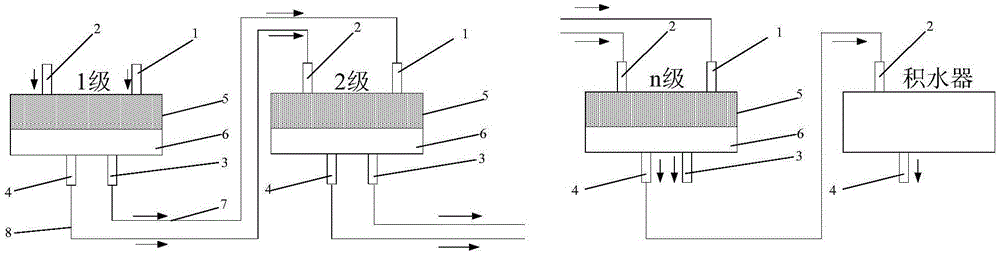

[0024] In order to better illustrate the technical solution of the present invention, the present invention will be further described below through the accompanying drawings and examples.

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Take the humidity generating ice surface saturator with the same five-cavity structure as an example.

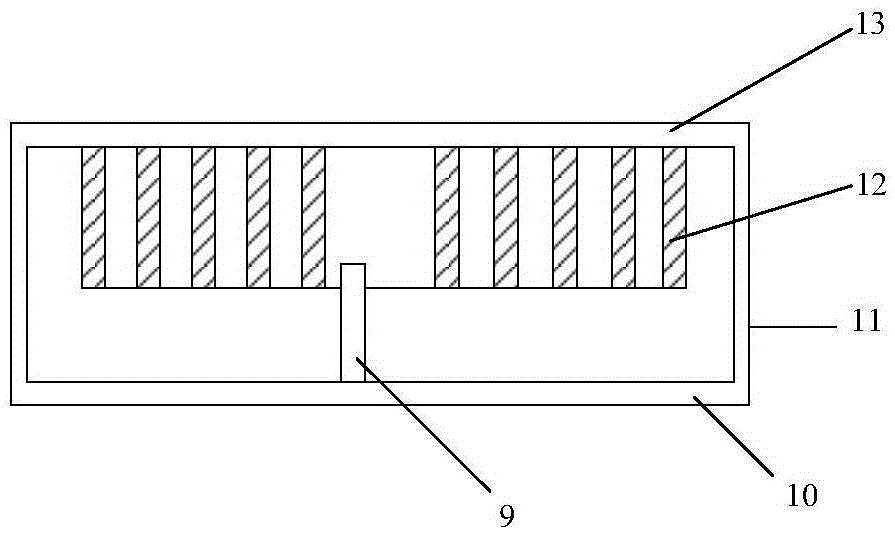

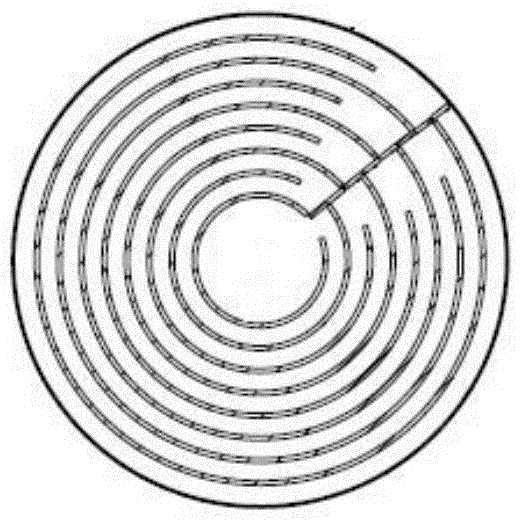

[0027] The cavity structure is attached figure 2 As shown, it is composed of a drain pipe 9, a bottom plate 10, an outer wall 11, an air chamber 12, and a top plate 13, with an inner diameter of 218 mm and a height of 36 mm, with an air inlet 1 and a water inlet at the upper end, and an air outlet 3 and a water discharge port 4 at the lower end. Threaded connection, each connection port is connected by 1 / 4" ferrule; conduit 7 is an inner polished stainless steel tube with an outer diameter of 6mm and an inner diameter of 4mm; conduit 8 is an inner polished stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com