Downhole flexible composite pipe service life prediction method

A flexible composite pipe and life prediction technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem of high temperature sensitivity of non-metallic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

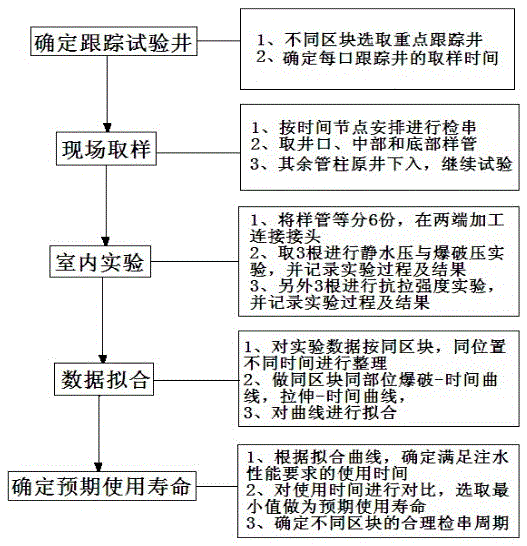

[0018] Such as figure 1 As shown, the present invention provides a method for predicting the service life of a downhole flexible composite pipe, comprising the following steps:

[0019] Step 1, select different test blocks, determine the follow-up test wells, and determine the sampling time of each follow-up test well;

[0020] Step 2: According to the determined sampling time, carry out serial inspection operation for each tracking test well. After the serial inspection operation is completed, perform wellbore sampling for each tracking test well, and take out the wellbore samples as sample tubes;

[0021] Step 3, the sample tube taken in step 2 is divided into two parts, one part is subjected to hydrostatic pressure and burst pressure tests, and the other part is subjected to tensile tests;

[0022] Step 4, according to the hydrostatic pressure, burst pressure test and tensile test carried out in step 3, respectively draw the burst pressure-time curve and the tensile streng...

Embodiment 2

[0030] In the process of carrying out wellbore sampling to each tracking test well in the described step 2, the wellbore sampling shall be carried out at the wellhead, the middle part and the bottom of the well respectively; in the described step 4, the breaking pressure-time curve and the tensile strength-time Curve, the blasting pressure-time curve and the tensile strength-time curve of wellhead, the middle part and the bottom of the well should be drawn respectively at the wellhead, the middle part and the bottom of the well, and then, carry out numerical fitting according to the trend respectively; The minimum expected service life value is the minimum value among the expected service life values at the wellhead, middle and bottom of the well.

Embodiment 3

[0032] In the second step, the wellbore is sampled from the wellhead, the middle part and the bottom of the wellbore, and at least 6 sample pipes of different lengths are taken from each part according to different lengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com