Probe of measuring gas-solid two-phase flow particle slip velocity and measurement method

A technology of sliding velocity and particles, which is applied in the direction of measuring fluid velocity using thermal variables, measuring devices, fluid velocity measurement, etc., can solve the problem that optical fiber probes cannot capture clear images, the lack of gas velocity and particle velocity measurement methods, and the lack of models Very good universality and other issues, to achieve the effect of facilitating particle identification, particle interpretation and identification, and solving the problem of insufficient light source intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention more clearly described, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

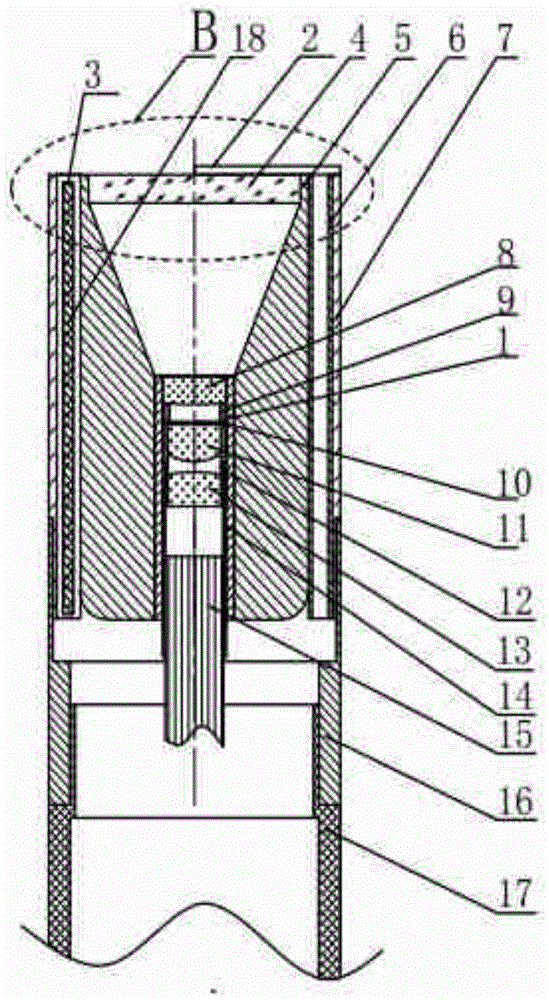

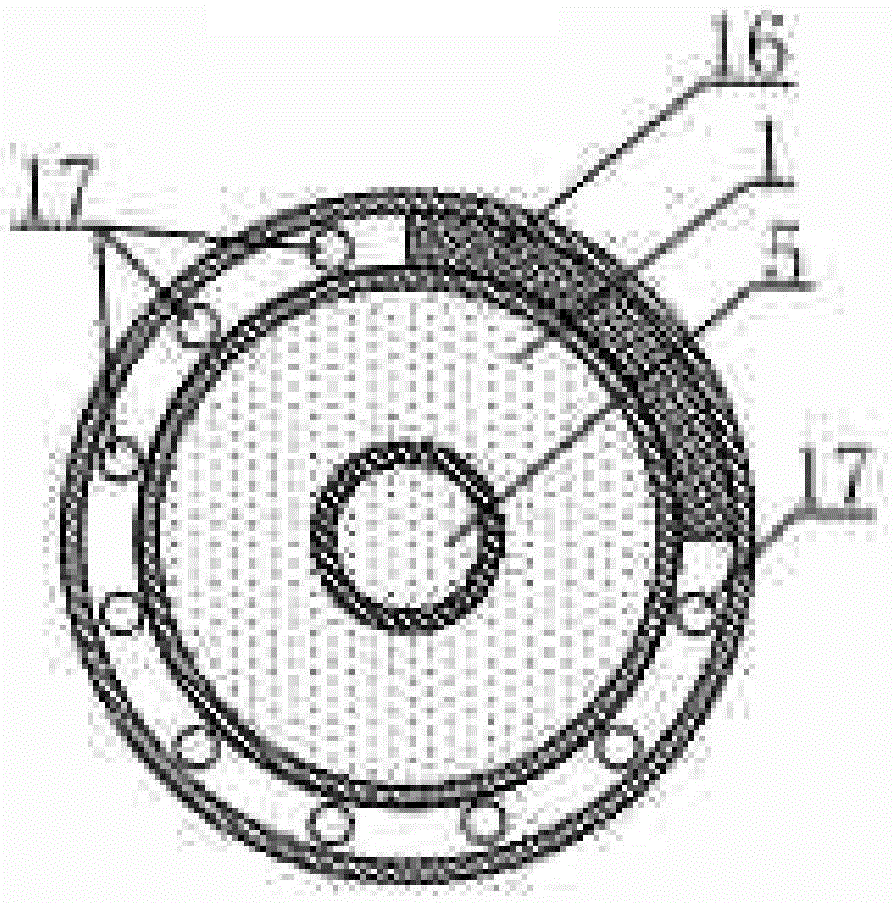

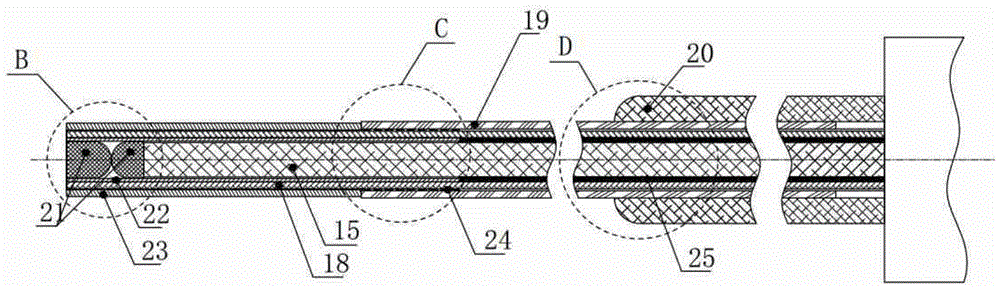

[0027] This embodiment provides a probe for measuring the slip velocity of particles in a gas-solid two-phase flow, which consists of three parts, namely an optical imaging unit, a hot film velocimetry unit and a light source transmission unit.

[0028] Wherein, the optical fiber imaging unit comprises an endoscope objective lens 1, a reflector 5, a glass flat plate 4 and a quartz optical fiber 15, the endoscope objective lens is arranged in the middle of the probe head end, and the whole probe head end is about 3 cm long, and the reflector 5 is installed At the front end of the endoscope objective lens 1, the front end of the reflector 5 is sealed with a glass plate 4; the quartz optical fiber 15 is connected to the rear end of the endos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com