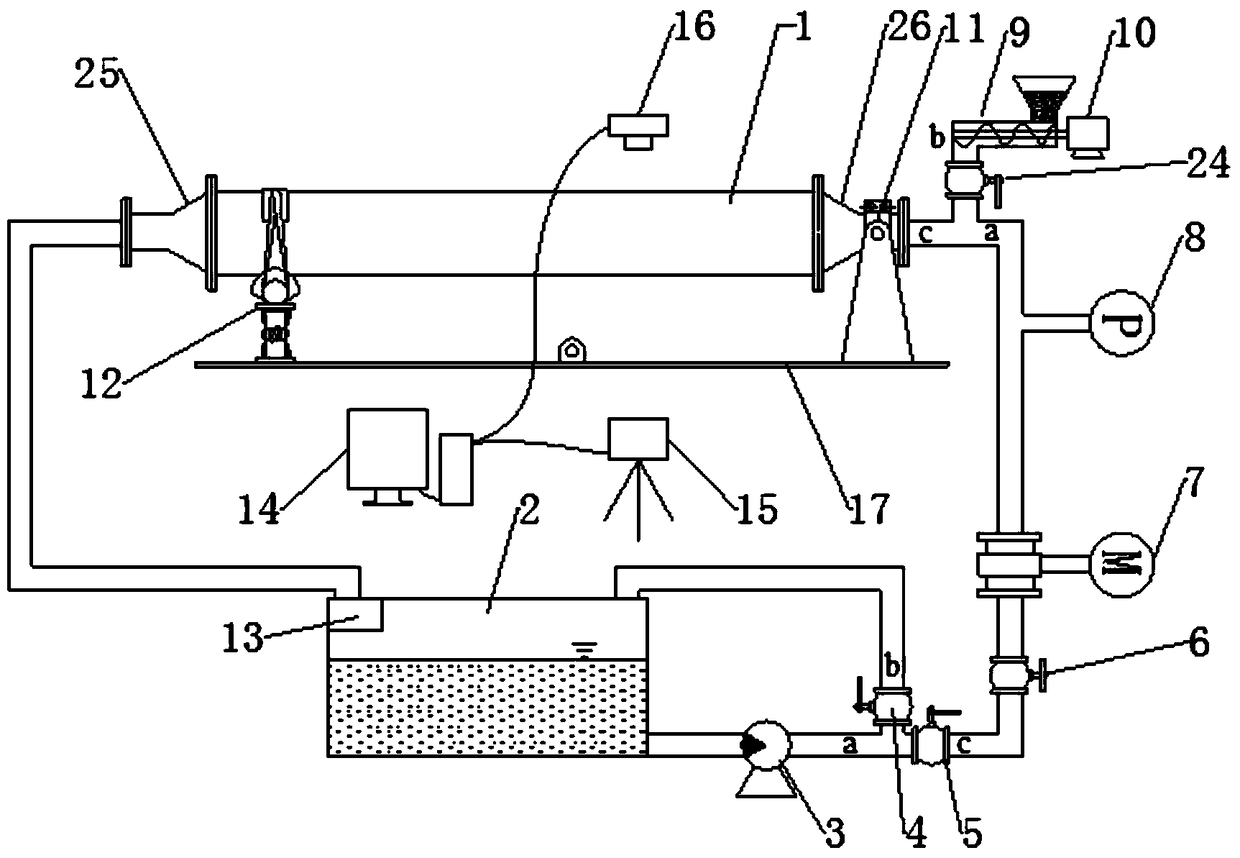

Experimental method and experimental device for comprehensive simulation of cuttings migration in horizontal directional drilling annular space

A technology for simulating experimental devices and horizontal directional drilling, which is applied in teaching models, educational appliances, instruments, etc., can solve the problems of simulation methods and devices that have not yet appeared, and achieve the effects of saving mixing and preparing devices, saving experimental expenses, and facilitating preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

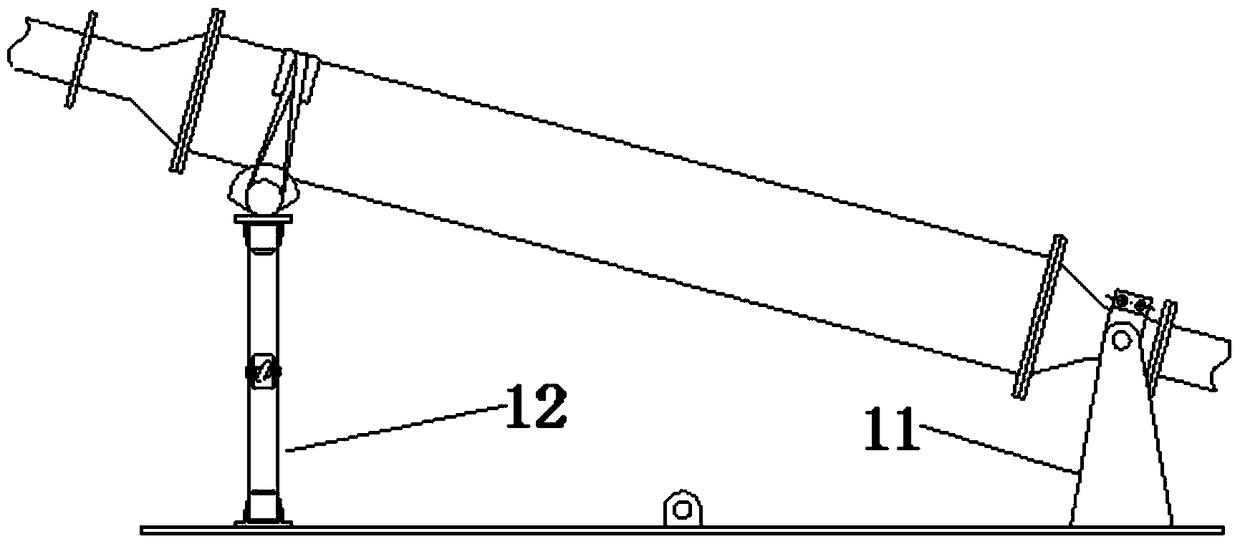

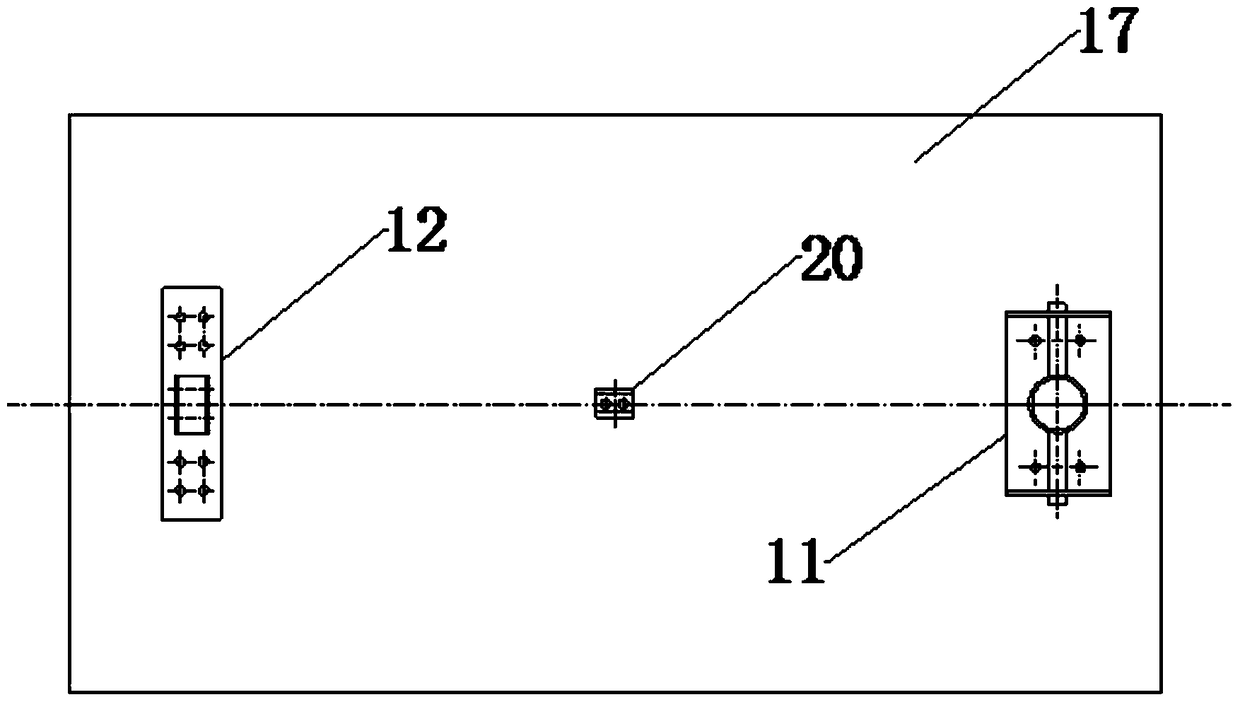

[0043] The present invention will be further described below in conjunction with drawings and embodiments.

[0044] The invention provides a comprehensive simulation experiment method for cuttings migration in the horizontal directional drilling annular space, which comprises the following steps:

[0045] (1) Initialization:

[0046] Put the transparent pipe horizontally, inject cuttings into the mud at a steady speed, input the mud at a steady flow rate into the injection end of the transparent pipe, observe the formation of the cuttings bed in the transparent pipe, take horizontal photos and vertical photos of the cuttings bed in the transparent pipe Take photos, measure the mud pressure and mud flow of the transparent pipeline, and record the total amount of cuttings added;

[0047] (2) Adjust the mud input speed:

[0048] Adjust the speed of mud input into the transparent pipe, observe the change of the cuttings bed in the transparent pipe, take horizontal and vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com