Hydrophilic hydroxyl polychlorinated biphenyl molecularly imprinted solid-phase extraction filler as well as preparation method and application thereof

A hydroxypolychlorinated biphenyl and molecular imprinting technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of staying in the evaluation stage of polymer physical properties and separation performance, and solve the problem of template leakage, The effect of improving selectivity and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

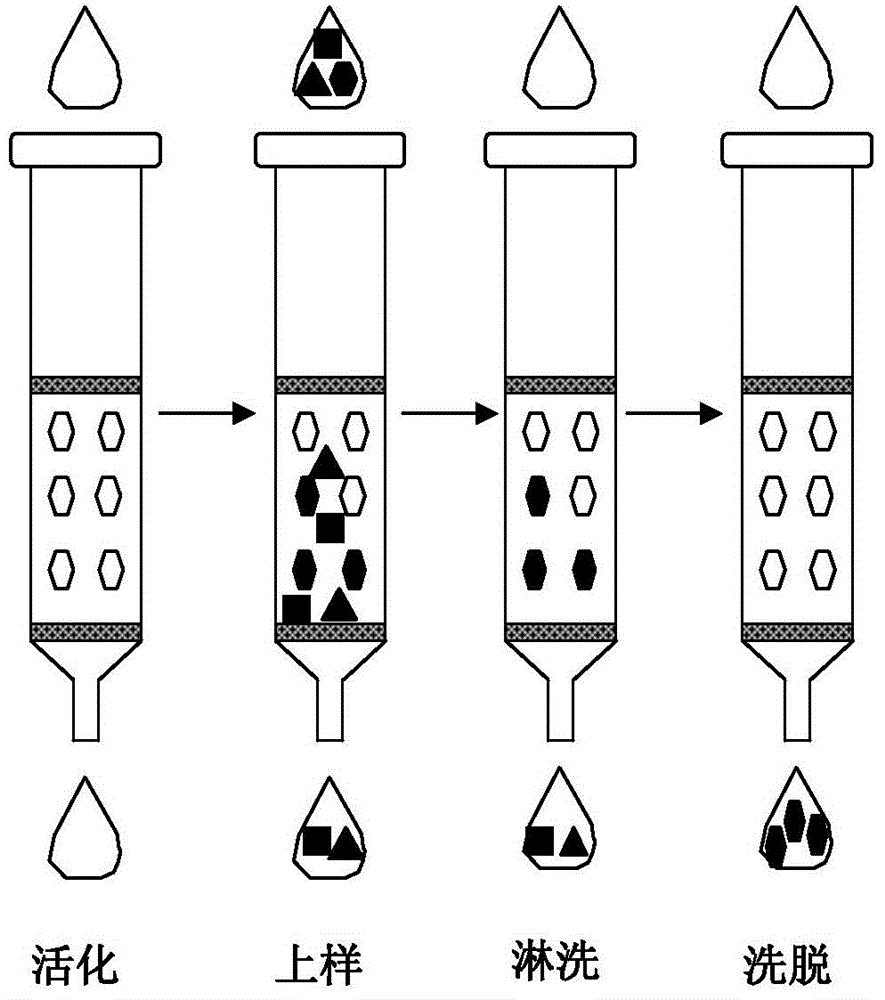

[0044] Take the separation and enrichment of hydroxy-polychlorinated biphenyls in water as an example. The operation steps are as follows:

[0045] (1) Preparation of hydrophilic hydroxy-polychlorinated biphenyl molecularly imprinted solid-phase extraction packing material and solid-phase extraction column

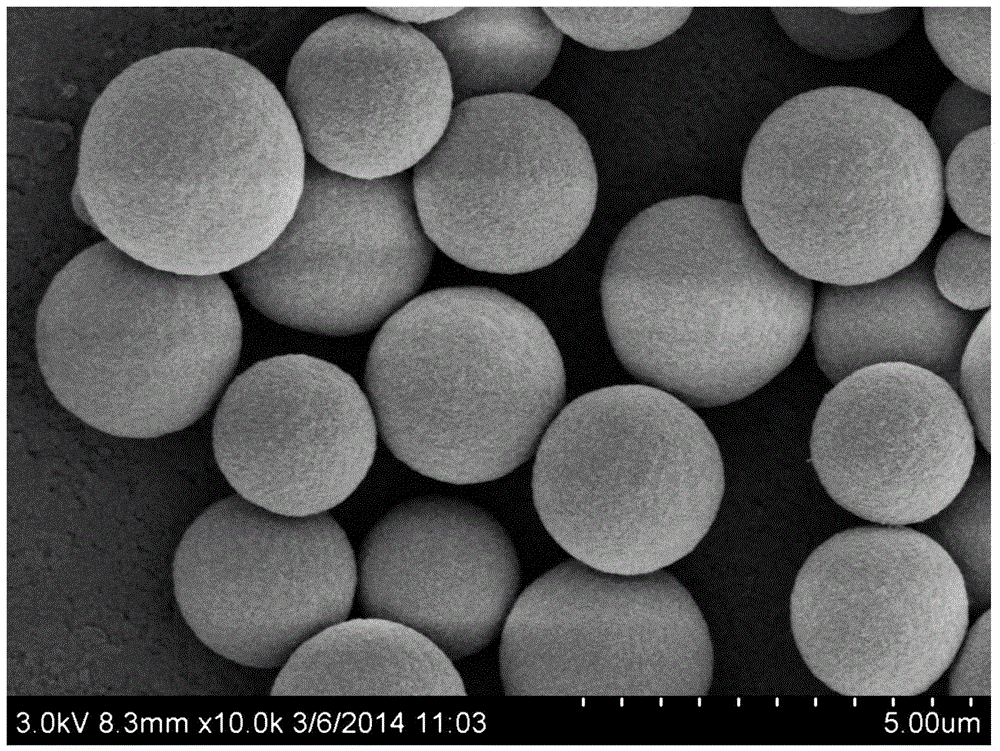

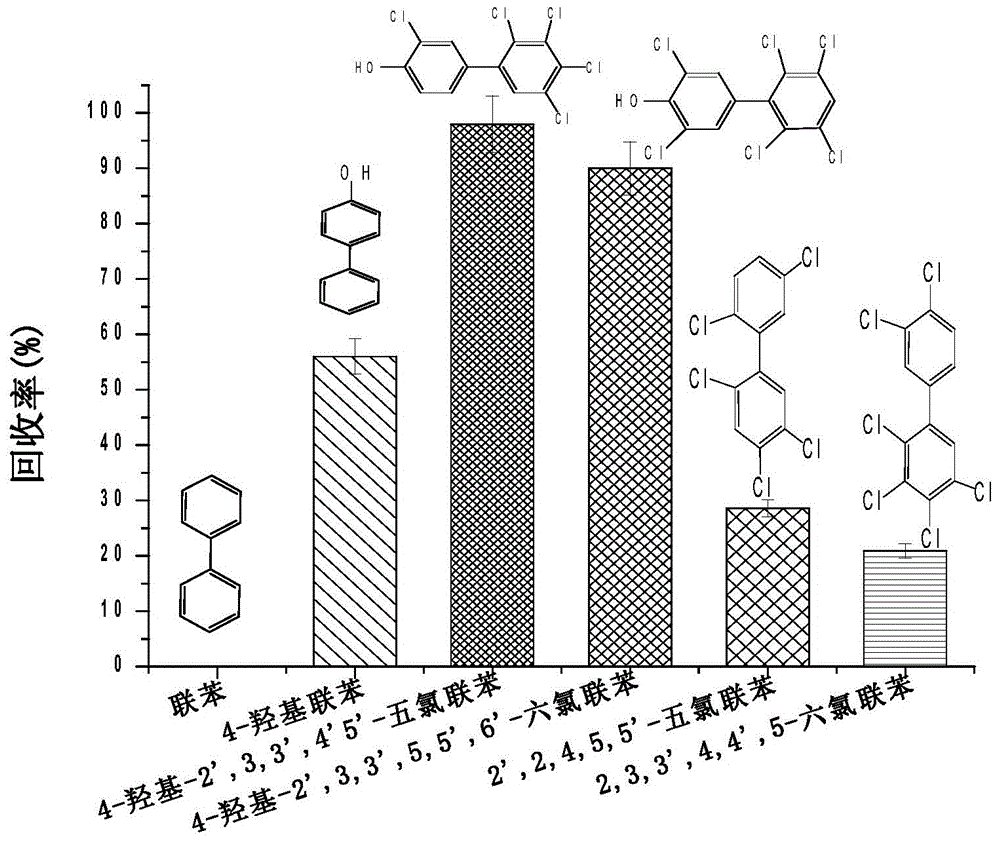

[0046] Dissolve 0.5 mM 4,4-dihydroxy-biphenyl and 3 mM acrylamide in 30 mL of acetonitrile solution, place in the dark for 1 hour, add 3 mM trimethylolpropane trimethacrylate (TRIM) and 50 mg azobisiso Nitrile (AIBN). Nitrogen gas was passed into the solution for 10 minutes, sealed, and reacted in a constant temperature oil bath at 70°C for 24 hours. The obtained polymer was vacuum-filtered to dryness, placed in a filter paper tube, and methanol-acetic acid (7:3, V:V) was used as the eluent, and the dummy template molecules were removed by Soxhlet extraction for 48 hours. The obtained imprinted polymer was vacuum-dried at 45° C. for 24 hours to obtain a hydroxy-PCB molecu...

Embodiment 2

[0057] Take the separation and enrichment of hydroxy-polychlorinated biphenyls in water as an example. The operation steps are as follows:

[0058] (1) Preparation of hydrophilic hydroxy-polychlorinated biphenyl molecularly imprinted solid-phase extraction packing material and solid-phase extraction column

[0059] For the preparation method of hydrophilic hydroxypolychlorinated biphenyl molecularly imprinted solid-phase extraction filler and solid-phase extraction column, except that the template molecule is changed to 0.5mM 4-hydroxybiphenyl and 0.5mM 2-hydroxybiphenyl, please refer to the steps in Example 1 for other steps (1).

[0060] (2) Use the obtained solid-phase extraction column to separate and enrich the hydroxy-PCBs in the water

[0061] For the method of separating and enriching hydroxy-polychlorinated biphenyls in water using the obtained solid-phase extraction column, please refer to step (2) in Example 1.

Embodiment 3

[0063] Take the separation and enrichment of hydroxy-polychlorinated biphenyls in water as an example. The operation steps are as follows:

[0064] (1) Preparation of hydrophilic hydroxy-polychlorinated biphenyl molecularly imprinted solid-phase extraction packing material and solid-phase extraction column

[0065] For the preparation method of hydrophilic hydroxypolychlorinated biphenyl molecularly imprinted solid-phase extraction filler and solid-phase extraction column, except that the functional monomer is changed to 2,6-diaminopyridine, please refer to step (1) in Example 1 for other steps.

[0066] (2) Use the obtained solid-phase extraction column to separate and enrich the hydroxy-PCBs in the water

[0067] For the method of separating and enriching hydroxy-polychlorinated biphenyls in water using the obtained solid-phase extraction column, please refer to step (2) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com