A hand-propelled mixer

A propellant stirring and agitator technology, which is applied in chemical instruments and methods, mixers, dissolving and other directions, achieves the effects of easy operation, saving experimental expenses, and good popularization and application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

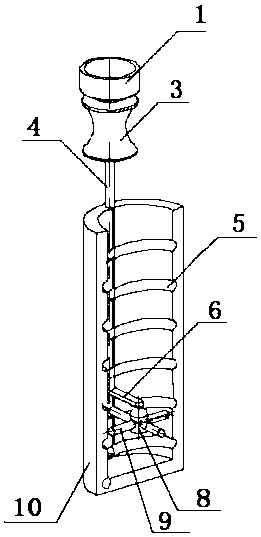

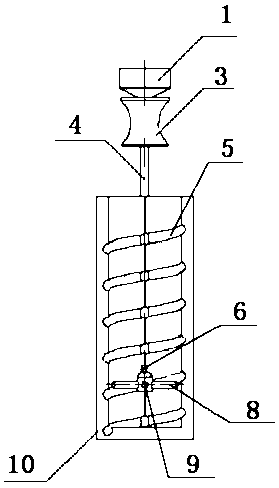

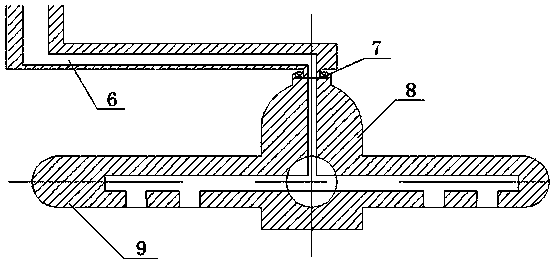

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Depend on Figure 1-4 It can be seen that a manual propulsion type agitator includes a feed hopper 1, a concave handle 3, a hollow handle 4, a hollow beam 6, a bearing 7, an agitator body 8 and a barrel body 10, and the bottom of the feed hopper 1 A concave handle 3 is provided, and a hollow handle 4 is provided below the concave handle 3. The hollow handle 4 is located in the barrel body 10. The bottom end of the hollow handle 4 is provided with a hollow beam 6. The hollow beam 6 The end is connected with the agitator main body 8 under it through a bearing 7; the bearing 7 is a ball bearing, wherein the lower end of the feed hopper 1 and the bearing 7 are all provided with holes, and the hollow lifting rod 4, the hollow beam 6 and the There are pipes in the middle of the mixer main body 8, and the liquid enters the bottom of the barrel body 10 through the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com