Core melt grouping trapping and cooling system

A core melt and cooling system technology, which is applied to cooling devices, reactors, nuclear power generation, etc., can solve the problem of group capture and cooling of core melt that has not been considered, and achieve simplification of post-accident treatment and radiation exposure. Dose Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

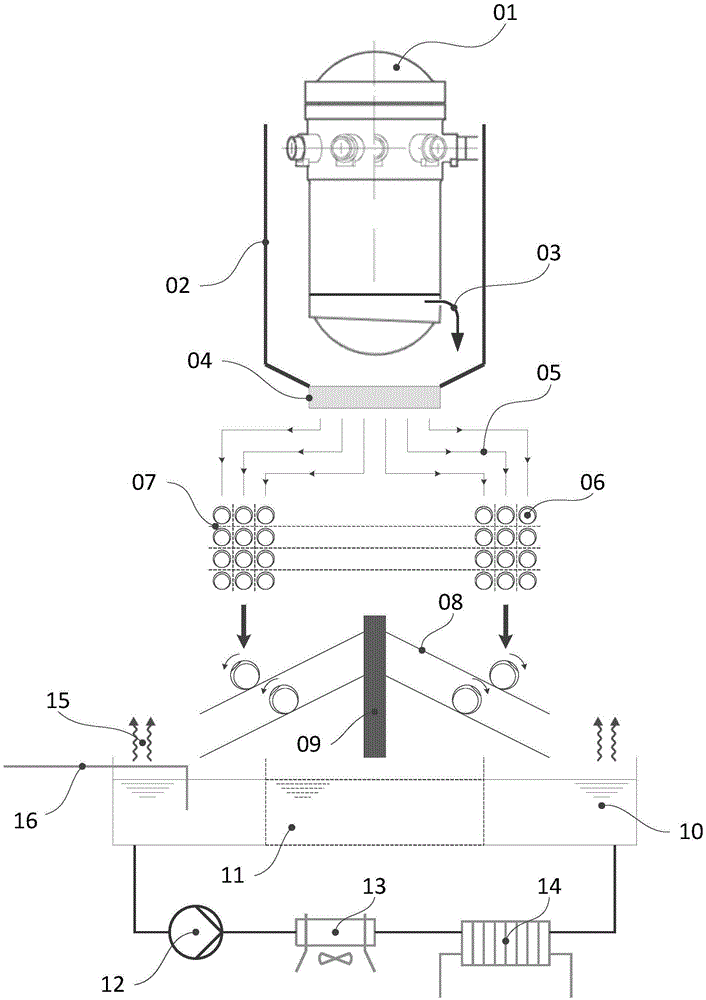

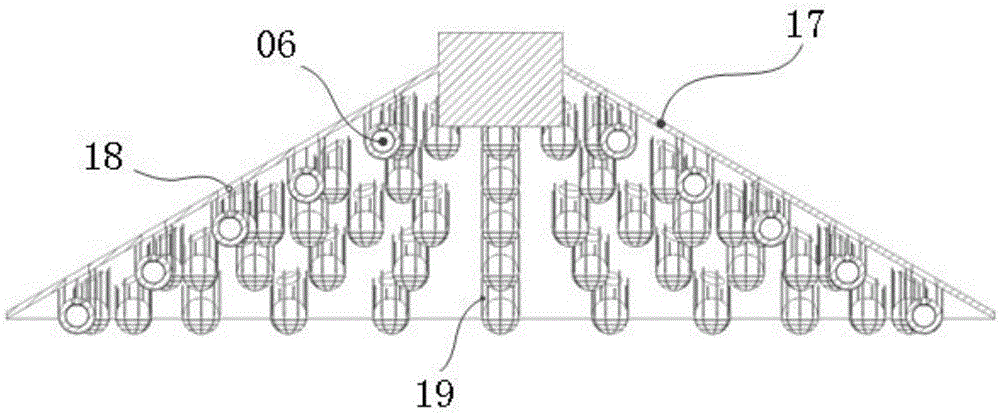

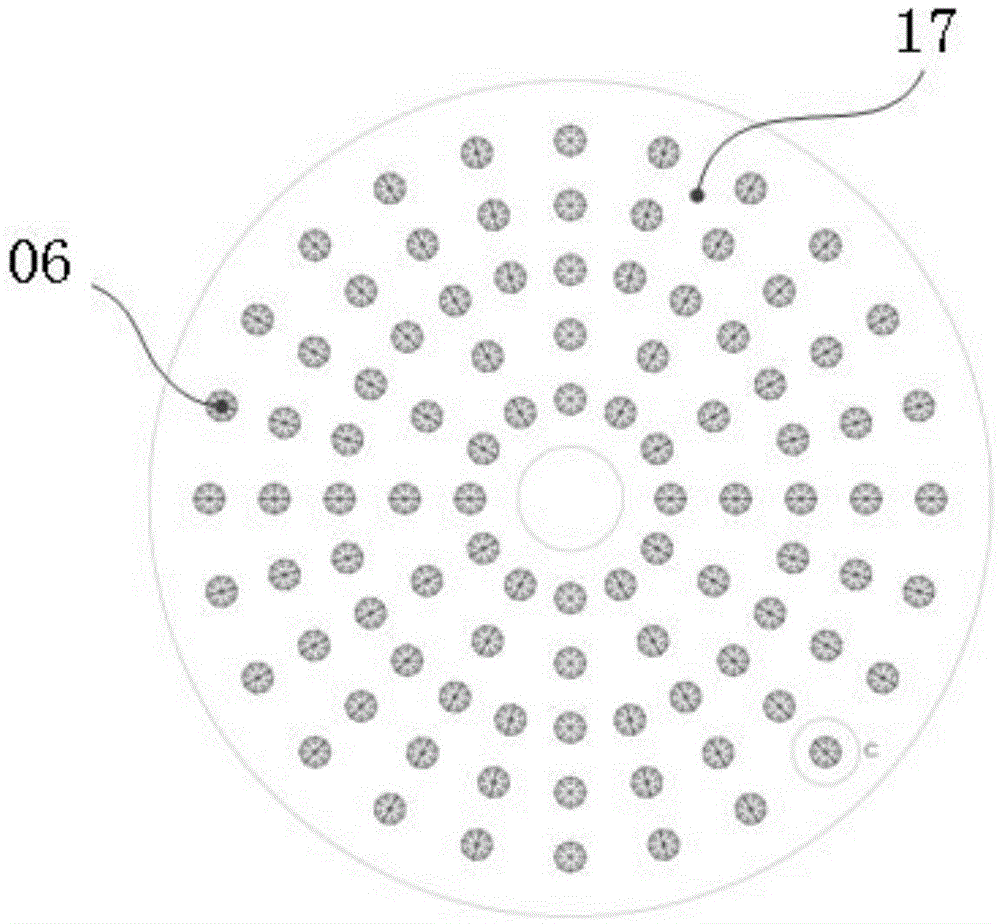

[0027] Such as figure 1Shown is the core melt group capture and cooling system provided by the present invention, including the group capture system and the cooling system. The grouping collection system includes a melt distribution device 04, a plurality of melt transfer channels 05, a plurality of melt collection containers 06, a fixed structure of the melt collection container 07, and a collection container transfer device 08; the melt distribution device 04 is set At the bottom of the reactor cavity 02, a plurality of melt collection containers 06 are arranged below the melt distribution device 04, and are connected to the melt distribution device 04 through a plurality of melt transfer channels 05, and the plurality of melt collection containers 06 is fixed on the smelt collection container fixing structure 07, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com