Direct current deicing method of extra-high voltage ground wires

A DC deicing and UHV technology, which is applied in the installation of cables, overhead lines/cable equipment, electrical components, etc., can solve problems such as complex weather conditions, long transmission distances, and large inductive reactance of ground wires, so as to improve deicing Efficiency, low cost, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

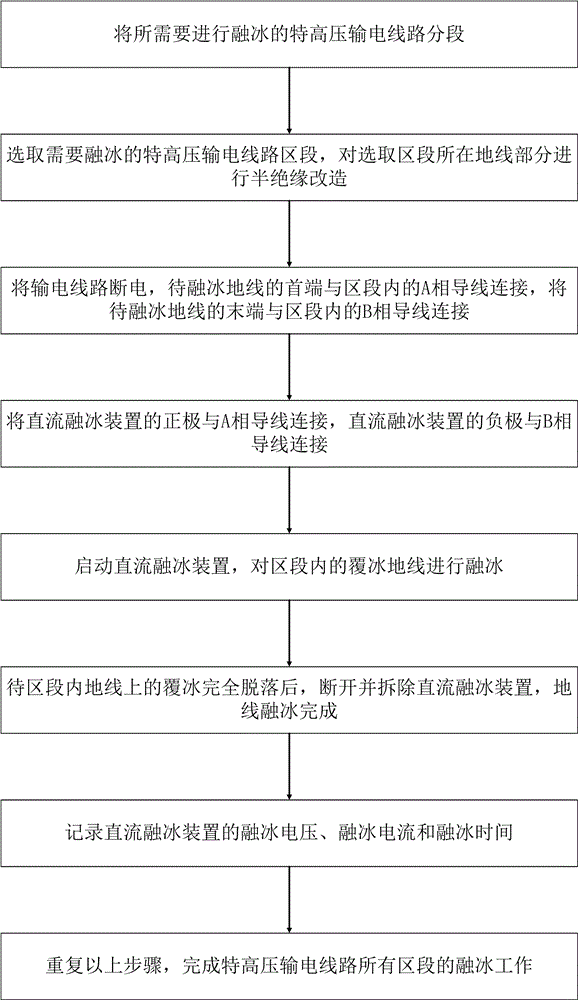

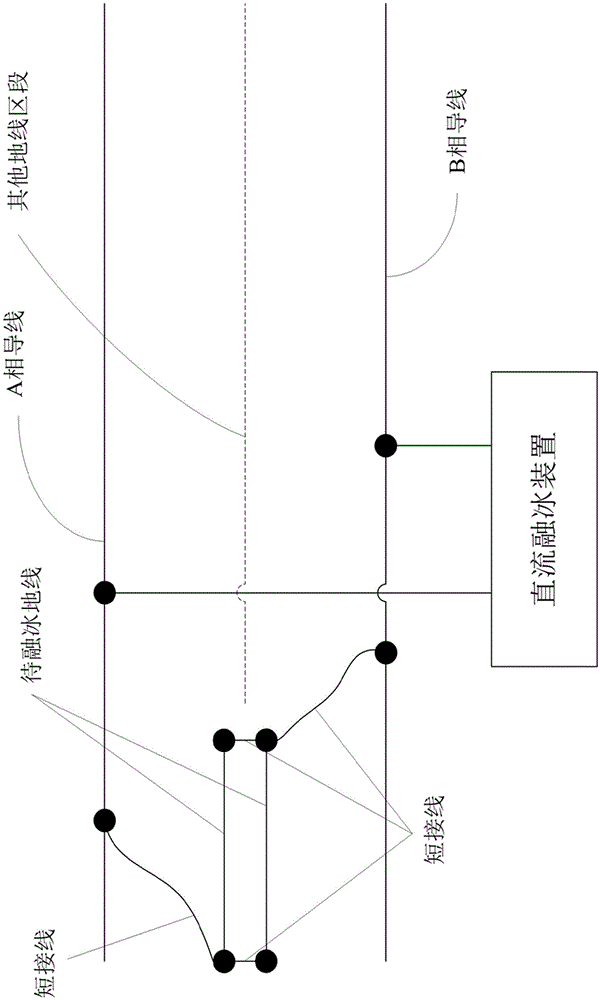

Method used

Image

Examples

Embodiment Construction

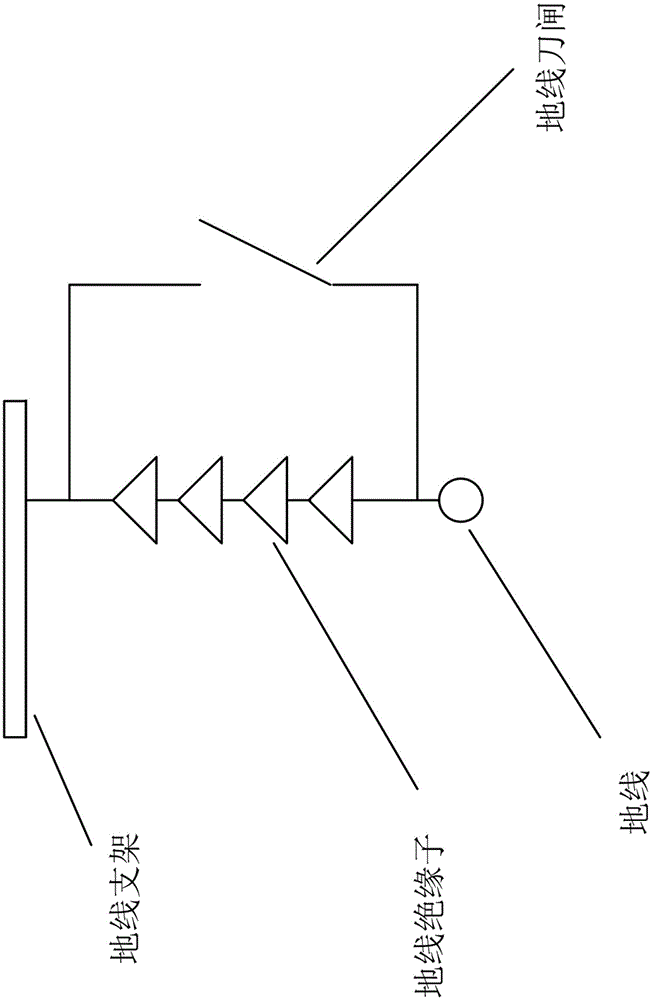

[0024] Such as figure 2 Shown is a schematic diagram of the ground wire semi-insulation transformation of the present invention: the ground wire semi-insulation transformation proposed by the present invention is different from the background technology by installing insulator strings and bypass knife switches between the ground wire and the ground wire support. Instead, a piezoresistor is installed between the ground wire and the ground wire support, which can realize the transformation of the semi-insulation of the ground wire, and ensure that the flow capacity of the piezoresistor is greater than the maximum possible lightning current in the ice-melting area. And ensure that the residual voltage value of the varistor is 150%~250% of the maximum output voltage of the DC ice melting device. Due to the characteristics of the varistor, there is no need to install a bypass knife switch after installing the varistor, and the semi-insulation transformation described above does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com