Plant for the production of multiple synthesis lines

A technology of synthetic thread and collection device, which is applied in the production of complete sets of equipment for artificial thread, filament generation, melt spinning, etc., can solve the problems that are not suitable for selective production, etc., and achieve the effect of compact arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

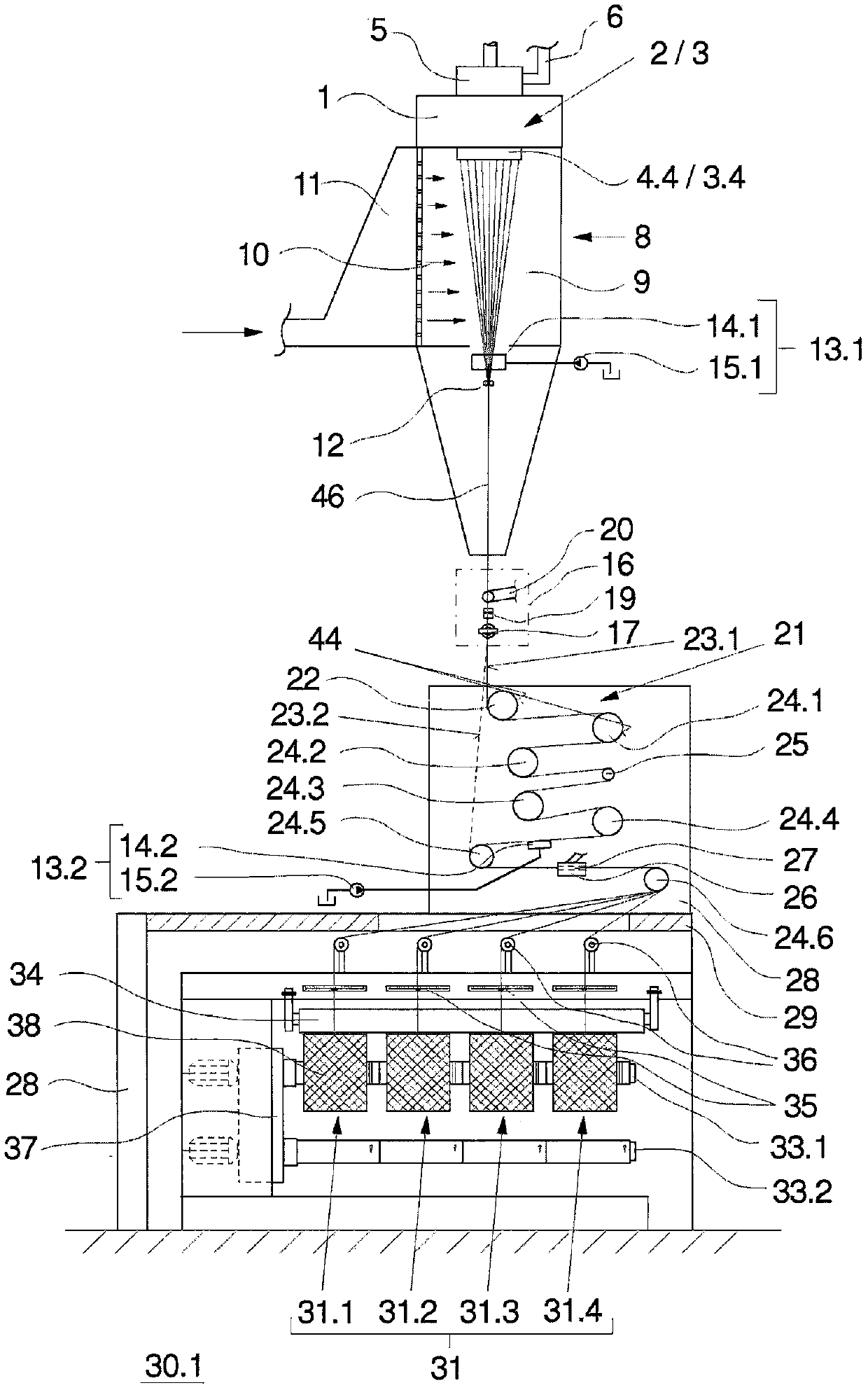

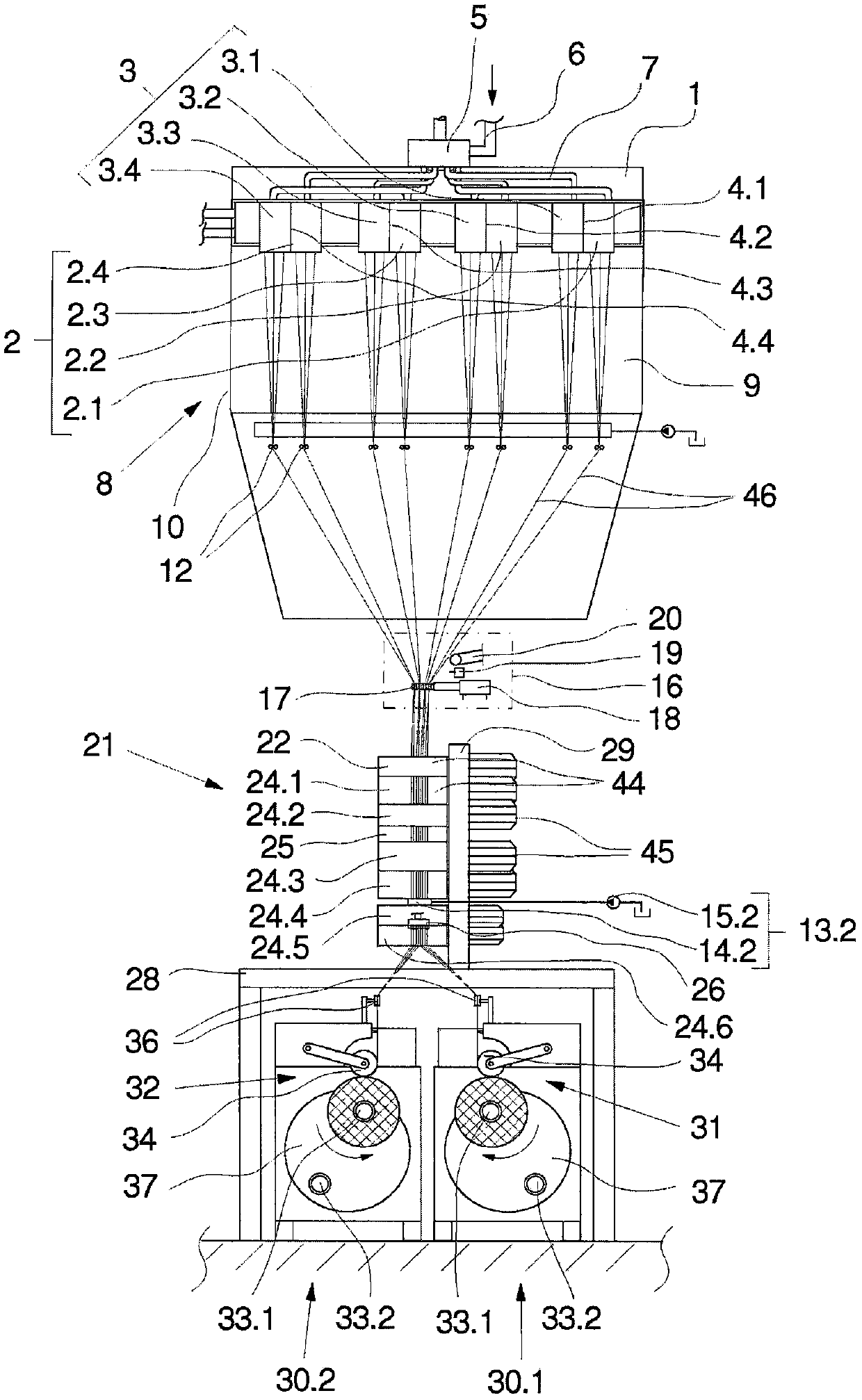

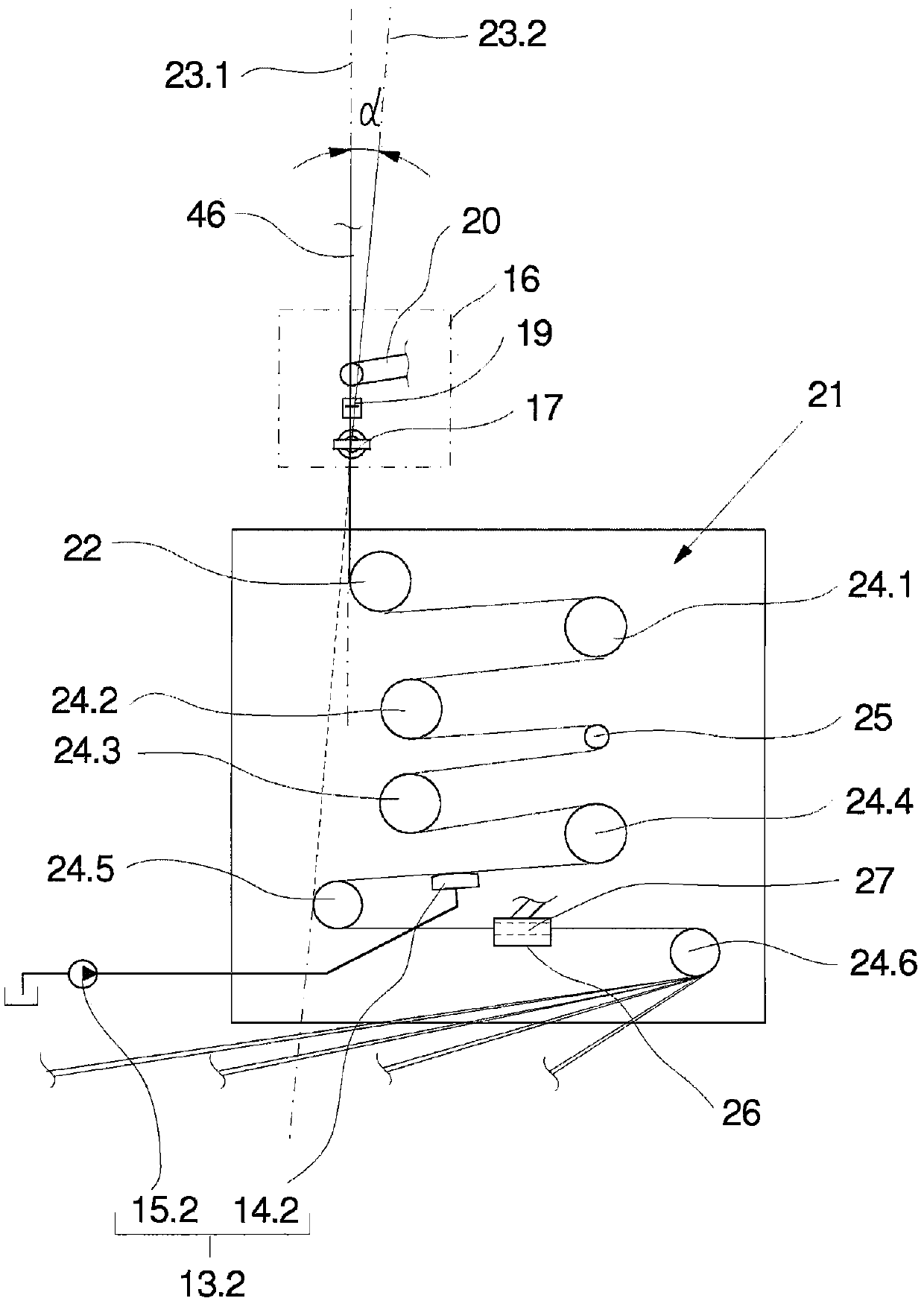

[0028] A first exemplary embodiment of the device for producing a plurality of synthetic lines according to the invention is in figure 1 and figure 2 is shown schematically in several views. This device is in figure 1 shown in cross-section in the figure 2 Shown in longitudinal view. If neither schematic is explicitly mentioned, the following description applies to both views.

[0029] figure 1 and figure 2 The apparatus shown in has two spinning nozzle groups 2 and 3 . The spinning nozzle group 2 and the spinning nozzle group 3 each comprise a total of four separate spinning nozzles arranged in a row. as specific from figure 2 It can be seen from the figure that the two spinning nozzle groups 2 and 3 and their spinning nozzles are composed of multiple spinning nozzles 4.1 to 4.4. Each of the multiple spinning nozzles 4.1 to 4.4 thus respectively contains one spinning nozzle 2.1 of the spinning nozzle group 2 and one spinning nozzle 3.1 of the spinning nozzle grou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap