Complanation cultivation board and cultivation method for black fungus

A cultivation method and planarization technology, which is applied in the field of black fungus flattened cultivation bacteria plate and cultivation field, can solve the problems that it is difficult to control the uniformity of the fungus bag environment, the maturity period of black fungus is inconsistent, and it is difficult to realize automatic control, etc., to achieve the solution of white fungus Pollution problems, shortening the effective production cycle, and saving the effect of cultivation sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

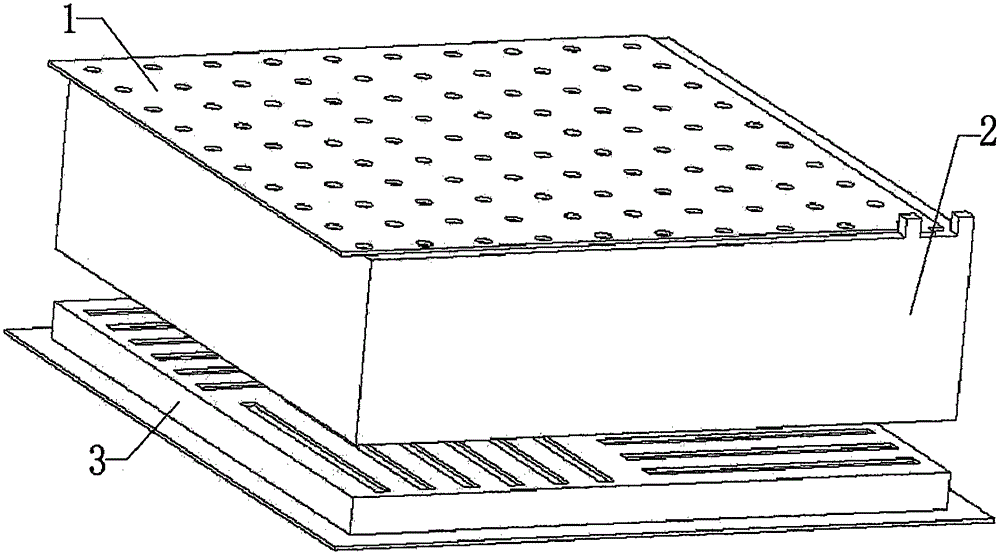

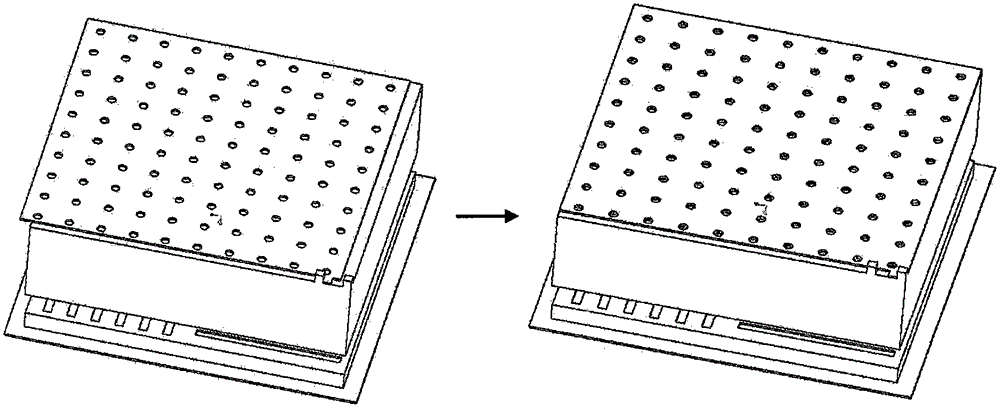

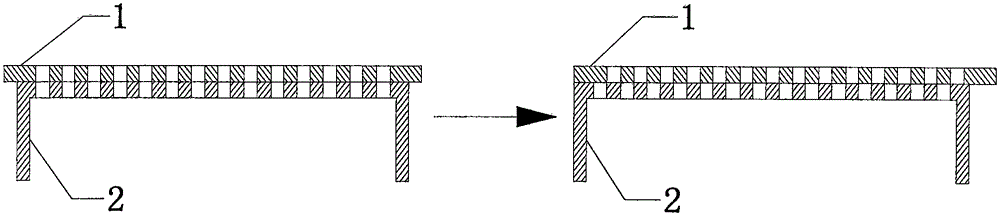

[0027] In order to enable those skilled in the art to better understand that the technical solution of the present invention can be implemented, the following in conjunction with the attached Figure 1-3 The present invention is further described with reference to specific examples, but the given examples are not intended to limit the present invention.

[0028] The invention provides a black fungus planarized cultivation fungus board, comprising a fungus cutting board 1, a fungus board shell 2 and a fungus board back cover 3, and the ear cutting board 1 is connected to the fungus by sliding rails on both sides of the upper surface of the fungus board shell 2. On the upper surface of the plate shell 2, the ear cutting plate 1 is provided with a plurality of through holes and is evenly distributed. The ear cutting plate 1 can move left and right on the upper surface of the bacterial plate shell 2. The upper surface of the 2 is provided with a plurality of through holes with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com