Multifunctional fresh milk pasteuring method and fresh milk pasteuring machine

A pasteurization and multi-functional technology, which is applied in the direction of milk preparations, milk preservation, dairy products, etc., can solve the problems that the water level cannot be guaranteed, the service life of the heating rod is affected, and the water level control is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

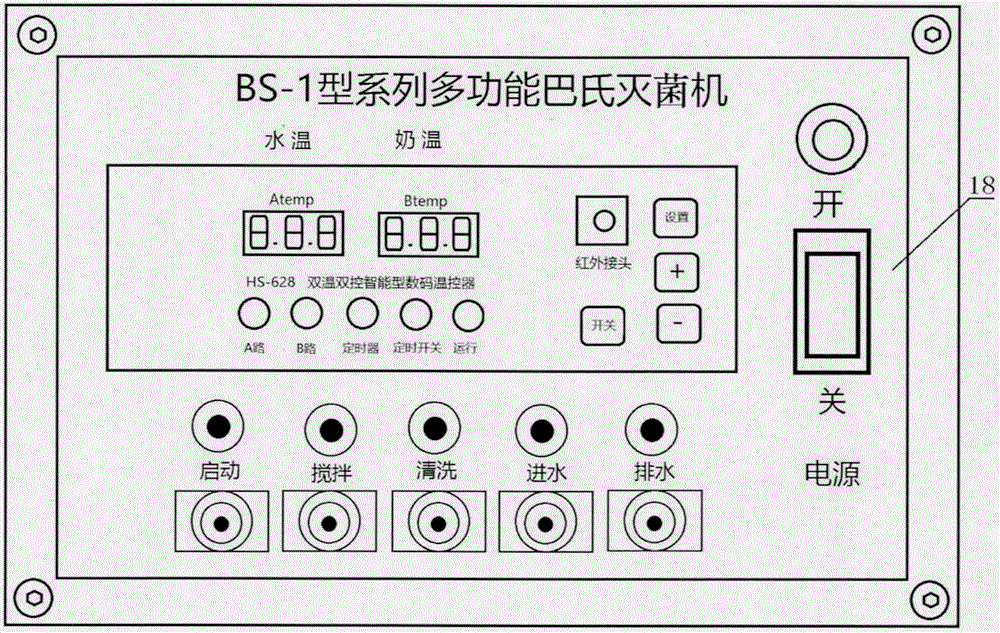

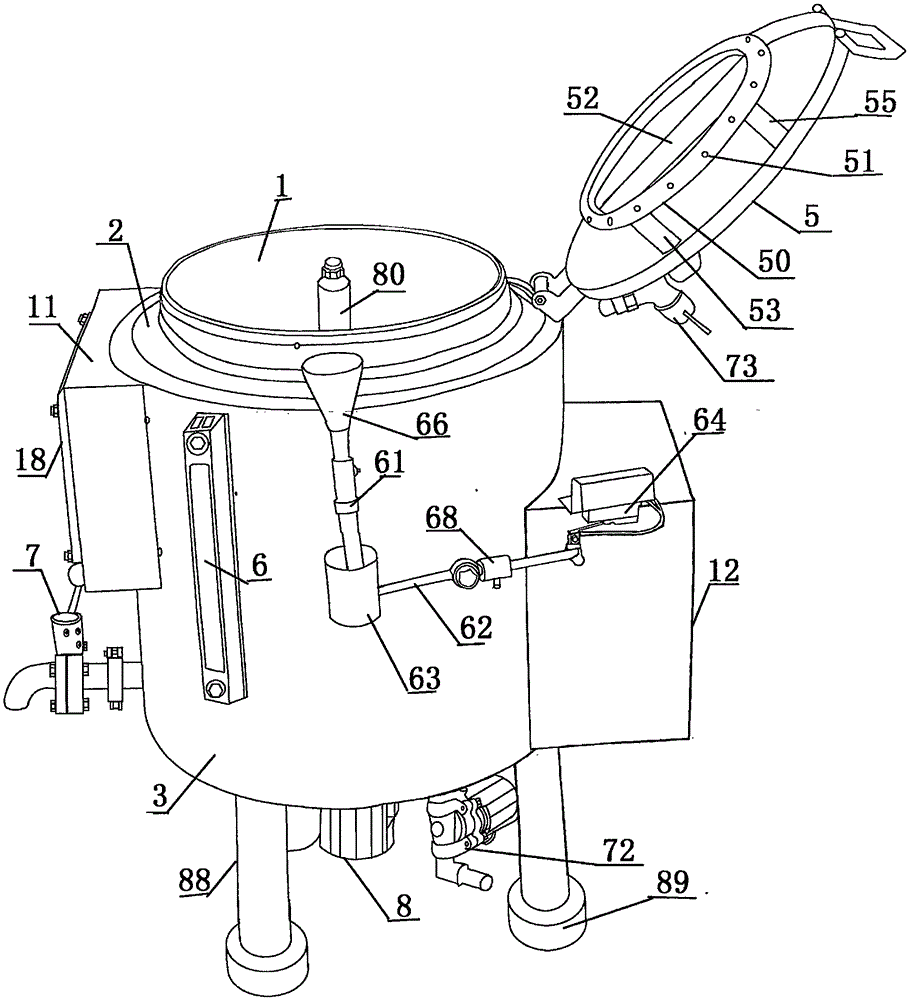

[0053] The multifunctional fresh milk pasteurization method of the present invention is to configure a water-bath jacket barrel with a heat-insulating layer and an outer shell on the periphery and below the milk barrel, and use the heating tube configured in the water-bath jacket to carry out the fresh milk under stirring. Heating, characterized in that the stirring is that the center of the bottom of the jacket barrel and the center of the bottom of the milk barrel are sealed and fixed up to the drive shaft sleeve on the upper part of the milk barrel. The agitating tube with multi-layer dials or blades is slipped to the outer periphery, and the output shaft of the drive motor installed on the lower surface of the jacket barrel is extended through the coupling to the drive shaft that passes through the drive shaft sleeve, and the upper part of the drive shaft passes through the bearing. It is slidingly matched with the upper end of the drive shaft sleeve in the circumferential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com