Slurry pond stirrer

A technology of agitator and slurry tank, which is applied to mixers with rotary stirring devices, chemical instruments and methods, dissolution and other directions, can solve the problems of large blade speed gradient, inability to take into account the stirring strength and prevention of segregation at the same time, and achieve material flow. The effect of increasing the range, complex and diverse movement forms, and high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

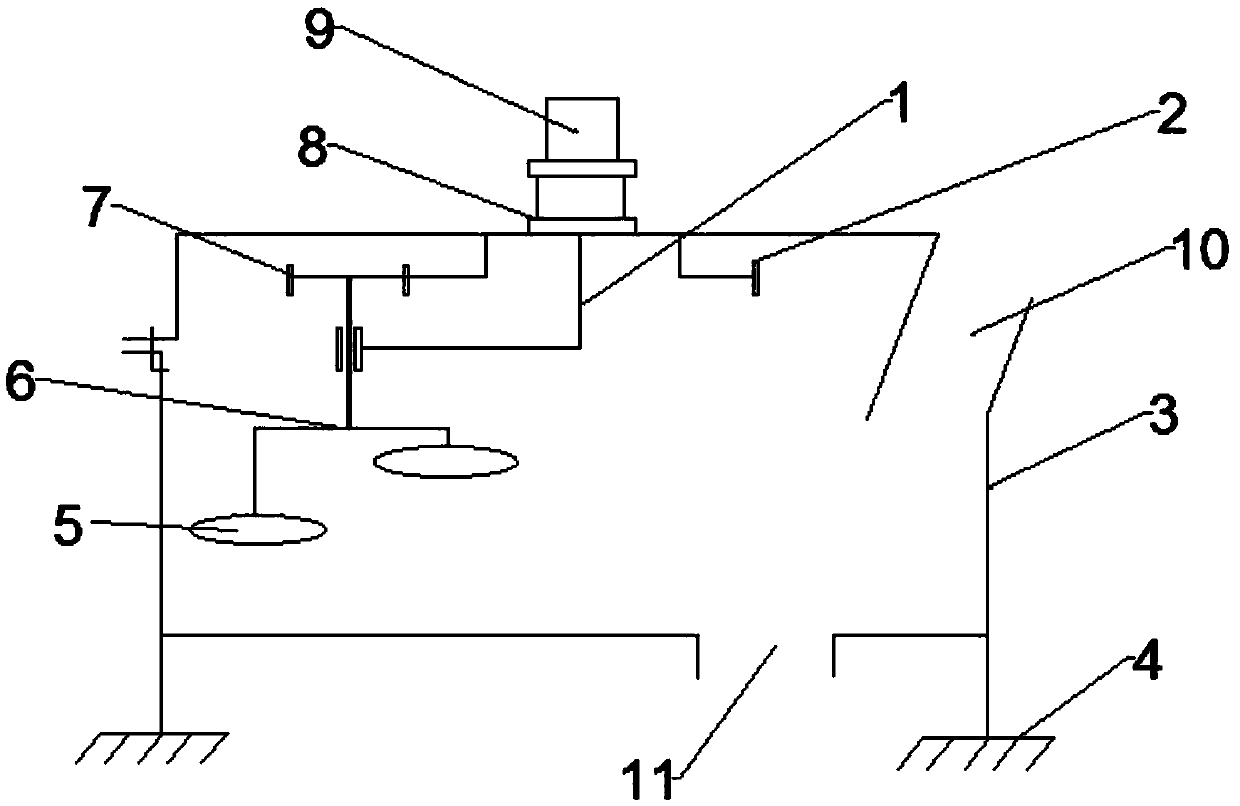

[0018] This embodiment provides a slurry tank agitator, such as figure 1 As shown, it includes a planetary carrier 1, a fixed ring gear 2, a cylinder body 3, an anchor 4, an annular blade 5, a stirring shaft 6, an internal meshing planetary wheel 7, a planetary reducer 8, a motor 9, a feed port 10 and Outlet 11, the planetary reducer 8 is arranged on the outer surface of the cylinder 3, the motor 9 is connected to the planetary reducer 8, the planetary reducer 8 is connected to the stirring shaft 6 through the planet carrier 1, and the stirring One end of the shaft 6 is connected with the internal meshing planetary wheel 7, and the other end is connected with the annular blade 5. The internal meshing planetary wheel 7 is connected with the inner surface of the cylinder 3, and the bottom of the cylinder 3 is connected with an anchor 4. The foot 4 is flush with the side surface of the cylinder body 3, the feed inlet 10 and the discharge outlet 11 are respectively arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com