Extrusion double coating method

A double-sided coating and extrusion coating technology, applied in the coating field, can solve problems such as low coating efficiency, high equipment and material loss, unstable service life of capacitors, etc., to improve stability and service life, reduce The loss of equipment and materials, the effect of accelerating the rate of evaporation of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

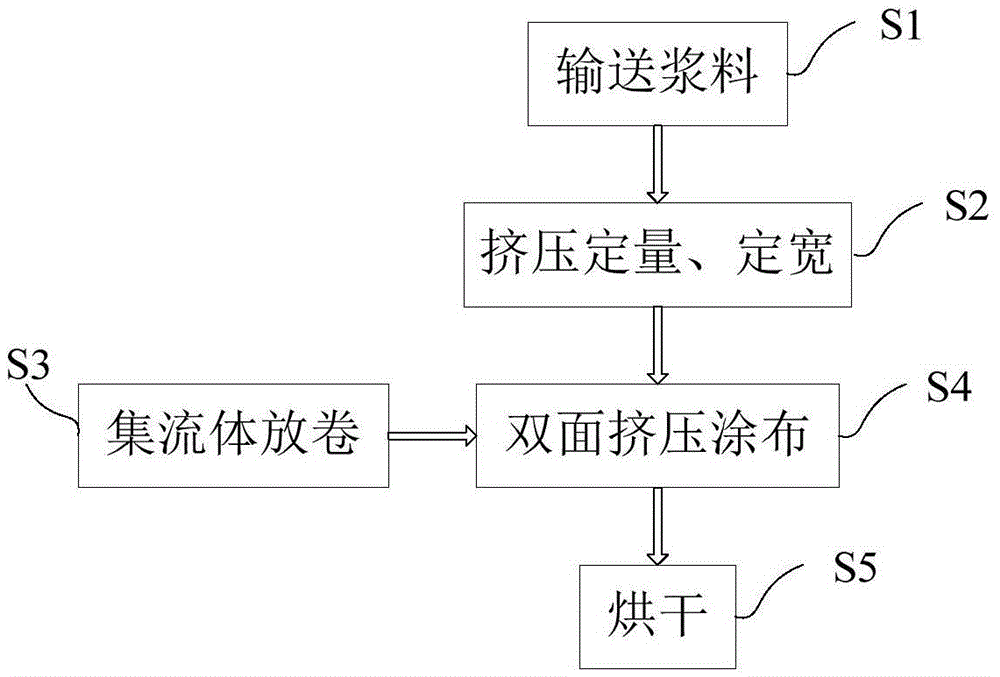

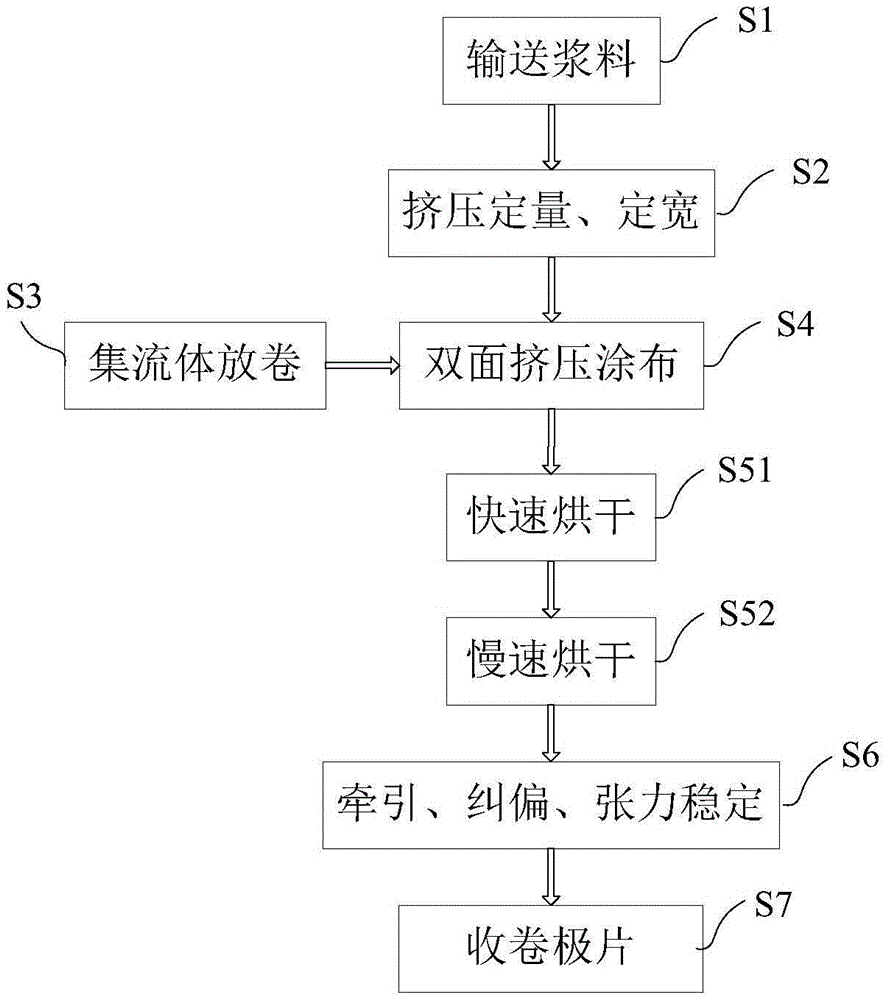

[0033] Embodiments of the present invention are as follows, see figure 1 , an extrusion double-sided coating method for the coating of capacitor pole pieces, comprising the following steps:

[0034] (1) Convey the slurry. After the slurry is stirred and filtered from the slurry transfer tank, it is input into the positive and negative extrusion head base through the metering pump;

[0035] (2) Extrude quantitative and fixed width, and set the coating width and extrusion coating gap through the extrusion die head;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com