Manufacturing technology of stainless steel box of dish-washing machine

A technology for stainless steel and dishwashers, which is applied in the field of manufacturing stainless steel cabinets of dishwashers. It can solve problems such as poor processing and process design, and insufficient depth of the secondary drawing of the water tank. Good effect, overall beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

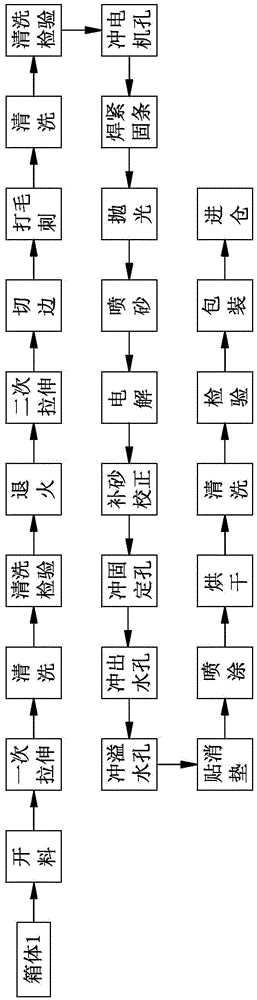

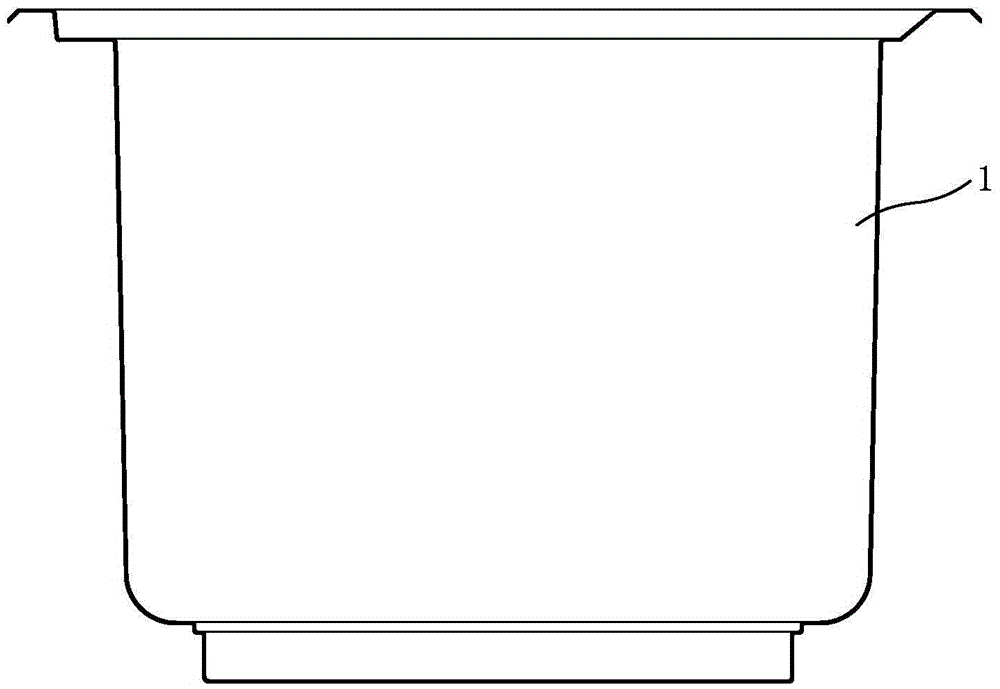

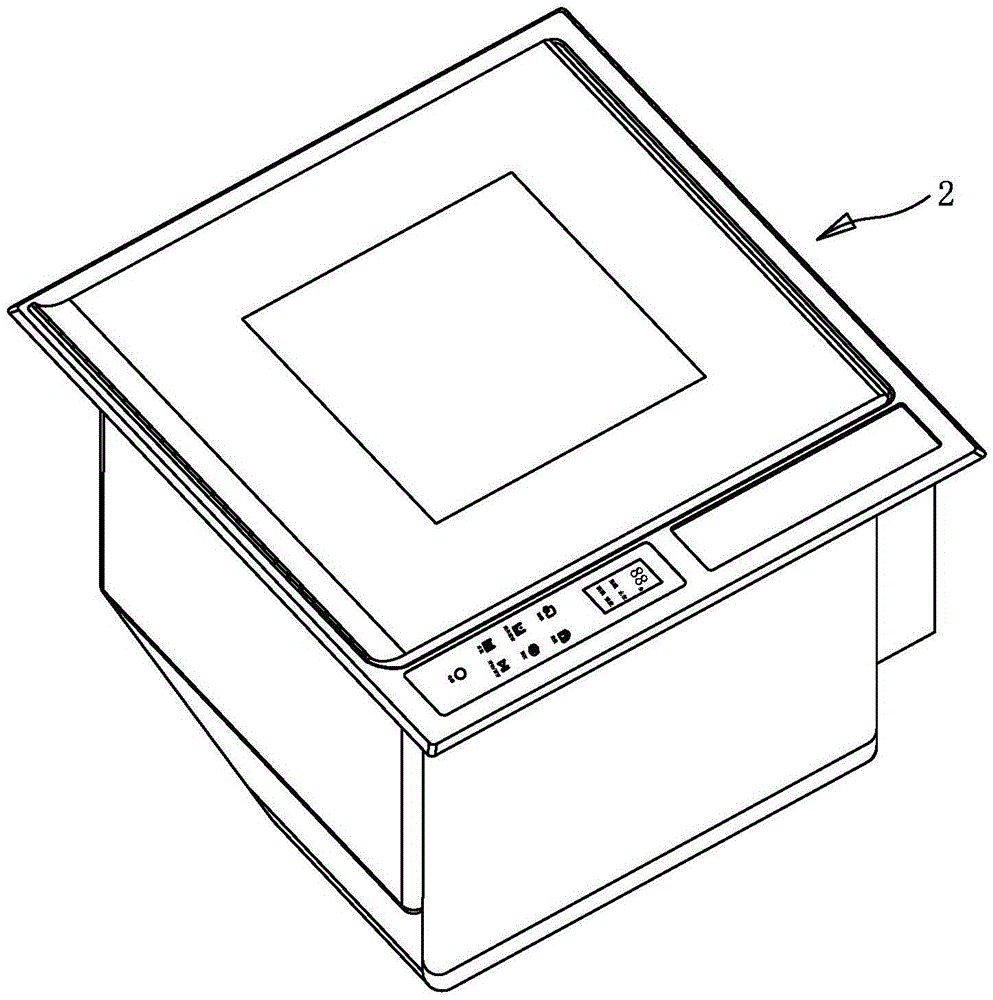

[0021] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as figure 1 As shown, the manufacturing process of the box body 1 is briefly summarized as follows: material cutting --- primary stretching --- cleaning --- cleaning inspection --- annealing --- secondary stretching --- trimming --- punching Burr---cleaning---cleaning inspection---punching motor hole---welding fastening strip---polishing---sand blasting---electrolysis---sand filling correction---punching fixing hole--- —Run out the water hole——Rinse the overflow hole——Paste the disinfection pad——Dry——Clean——Inspect——Package——Into the warehouse. Such as figure 2 , image 3 As shown, the prepared box is placed in the casing, and assembled with other components to form a dishwasher 2 for use.

[0022] The specific manufacturing process is as follows: the steel sheet block is made of 1000×1.2mm SUS304 (2B) stainless steel coiled steel plate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com