An automatic tool changer for scissor mechanism and its modular design method

A technology of automatic tool change and scissors, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as poor interchangeability, high design and maintenance costs, and complex mechanical structures, and reduce design and maintenance costs. cost, reduce post-maintenance cost, serialization and rapid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

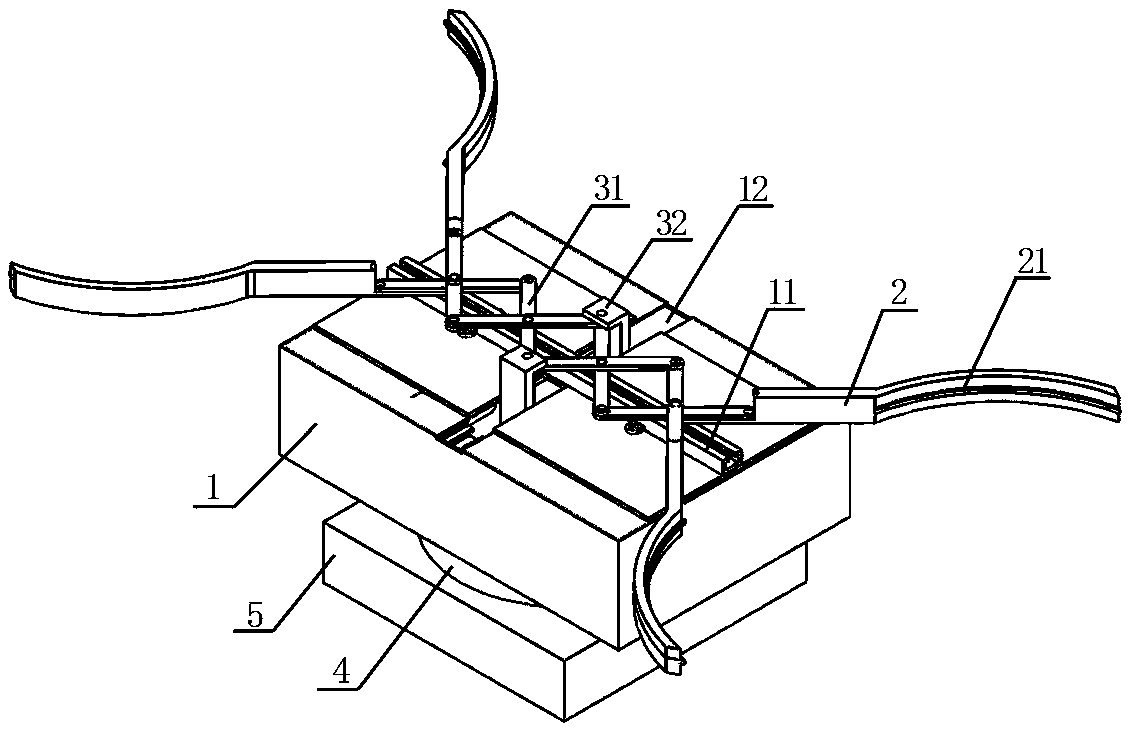

[0027] Such as figure 1 As shown, an automatic tool changer of a scissor mechanism, the automatic tool changer includes a transmission box 1, a mechanical claw 2, a telescopic mechanism, a rotating mechanism 4 and a lifting mechanism 5, and a positioning guide rail 11 is arranged on the transmission box 1 And the positioning guide groove 12, the telescopic mechanism includes a scissor mechanism 31, a control slider 32 and a motor, the scissor mechanism 31 is arranged on the positioning guide rail 11, the two ends of the scissor mechanism 31 are connected to the mechanical claw 2, and the mechanical claw 2 is set There is a pressure sensor 21, and the hinge pin in the middle of the scissors mechanism 31 is connected to the control slider 32. The control slider 32 is arranged on the positioning guide groove 12 of the transmission box 1 and is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com