Rotary adapter and mechanical hand with same

An adapter and manipulator technology, applied in the field of manipulators, can solve the problems of inaccurate stop position, high production cost, low sensitivity, etc., and achieve the effects of improving sensitivity, reducing volume and load, and improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

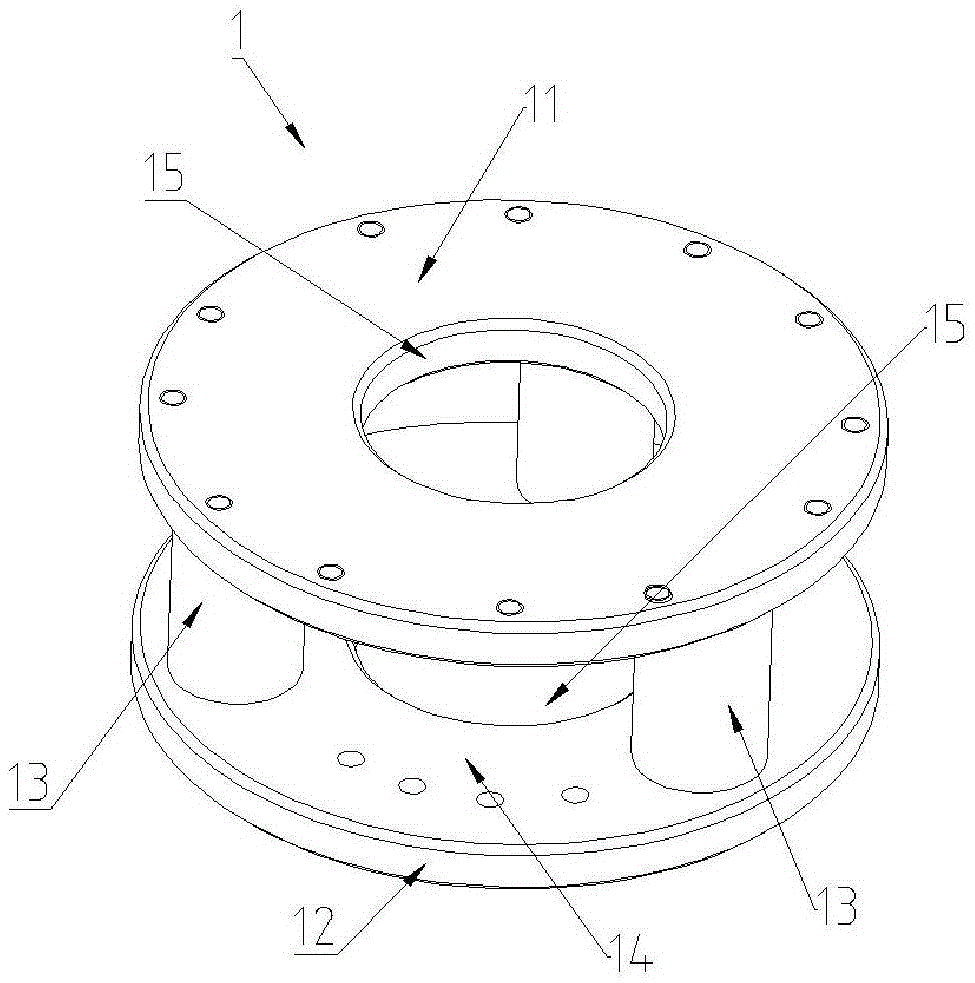

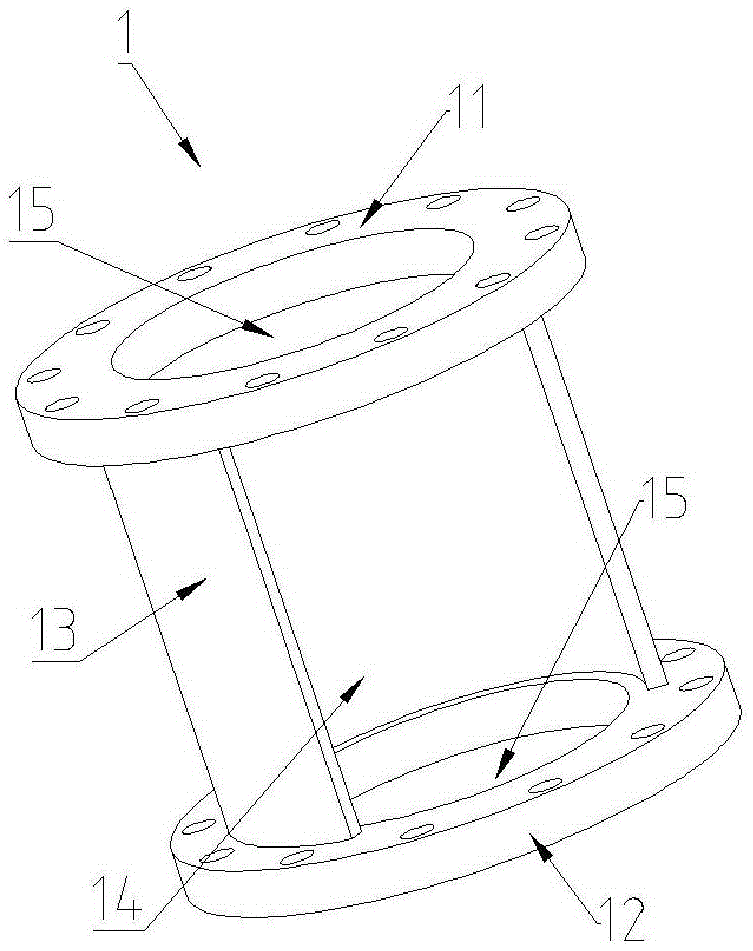

[0039] Such as figure 1As shown, the rotary adapter 1 of this embodiment includes an upper connecting plate 11, a lower connecting plate 12 and a connecting piece 13 connecting the upper connecting plate 11 and the lower connecting plate 12, and the upper connecting plate 11, the lower connecting plate A wire passing gap 14 is formed between 12 and the connecting piece 13 , and a wire passing through hole 15 communicating with the wire passing gap 14 is provided on the upper connecting plate 11 . The rotary adapter 1 is used to be installed between two relatively rotatable mechanical arms, the upper connecting plate 11 is used to connect one mechanical arm, and the lower connecting plate 12 is used to fix with the harmonic gear in the other mechanical arm connect. The wire passing through hole 15 and the wire passing gap 14 provide a convenient passage for the wiring of the driving motor or other components. The lower connecting plate 12 is provided with a wire passing hole ...

Embodiment 2

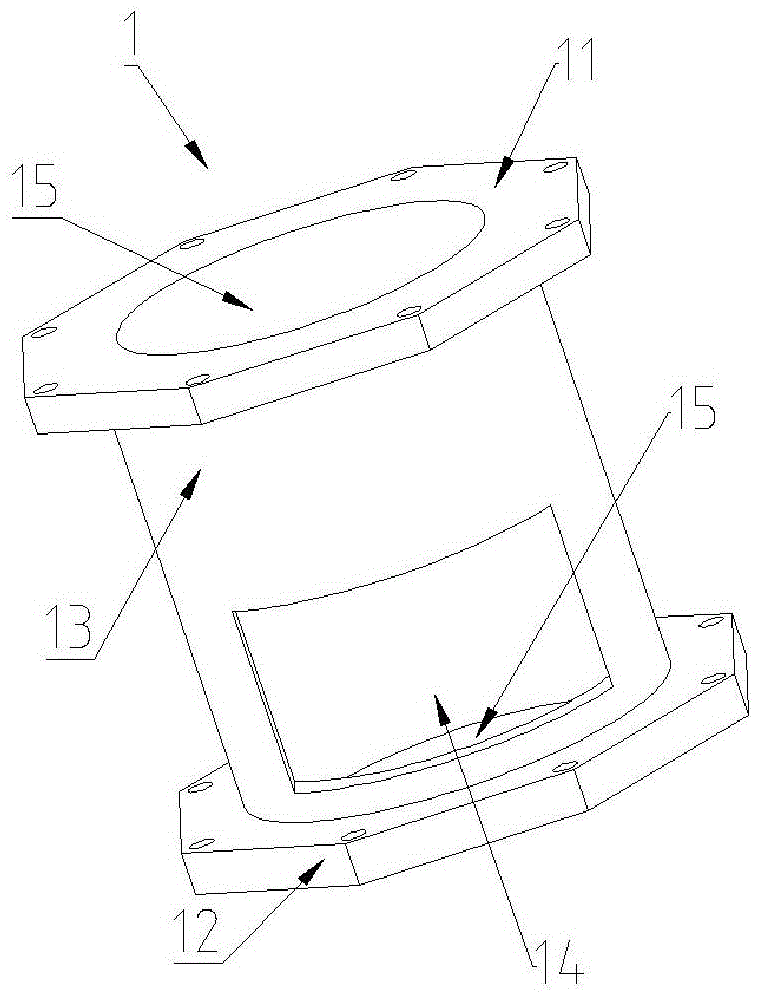

[0041] Such as Figure 2-4 As shown, the upper connecting plate 11 and the lower connecting plate 12 of the rotary adapter 1 are not limited to the ring shape shown in the first embodiment, they can also be Figure three Angular, regular polygon or other shapes. The connecting piece 13 is also not limited to the connecting column shown in the first embodiment, it can also be an incompletely closed connecting arm arranged between the upper connecting plate 11 and the lower connecting plate 12, or other connecting arms for wiring. The connector 13 at the hole position (that is, through the line gap 14).

Embodiment 3

[0043] Such as Figure 5-8 As shown, the manipulator of this embodiment at least includes a first manipulator 2 provided with a control panel 21, a second manipulator 3, a first harmonic gear 22 and a first drive installed in the first manipulator 2. The motor 23, the wave generator of the first harmonic gear 22 is directly connected to the output shaft of the first drive motor 23, and the manipulator also includes any one of the rotary adapters 1 in Embodiment 1 or 2, and the upper connection of the rotary adapter 1 The plate 11 is fixedly connected to the lower end of the second mechanical arm 3 , and the lower connecting plate 12 is fixedly connected to the flexspline of the first harmonic gear 22 . Certainly, the flexible spline or rigid spline of the harmonic gear can be used as the output wheel, while the rigid spline or flexible spline serving as the non-output wheel is directly or indirectly fixedly connected with the mechanical arm installed with the corresponding dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com