Pipe mold cleaning mechanism and pipe mold cleaning machine

A cleaning mechanism and cleaning machine technology, applied in the field of construction, can solve the problems of time-consuming and labor-intensive, low degree of automation, quality problems of pipe piles, etc., and achieve the effects of good cleaning effect, high degree of automation and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

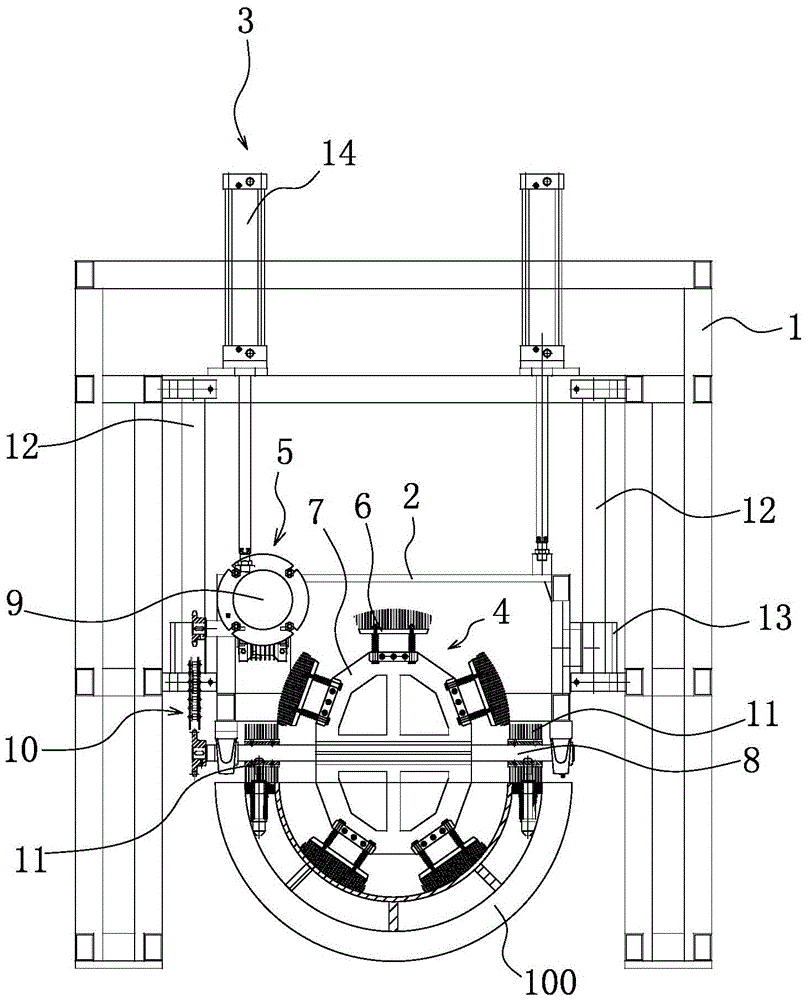

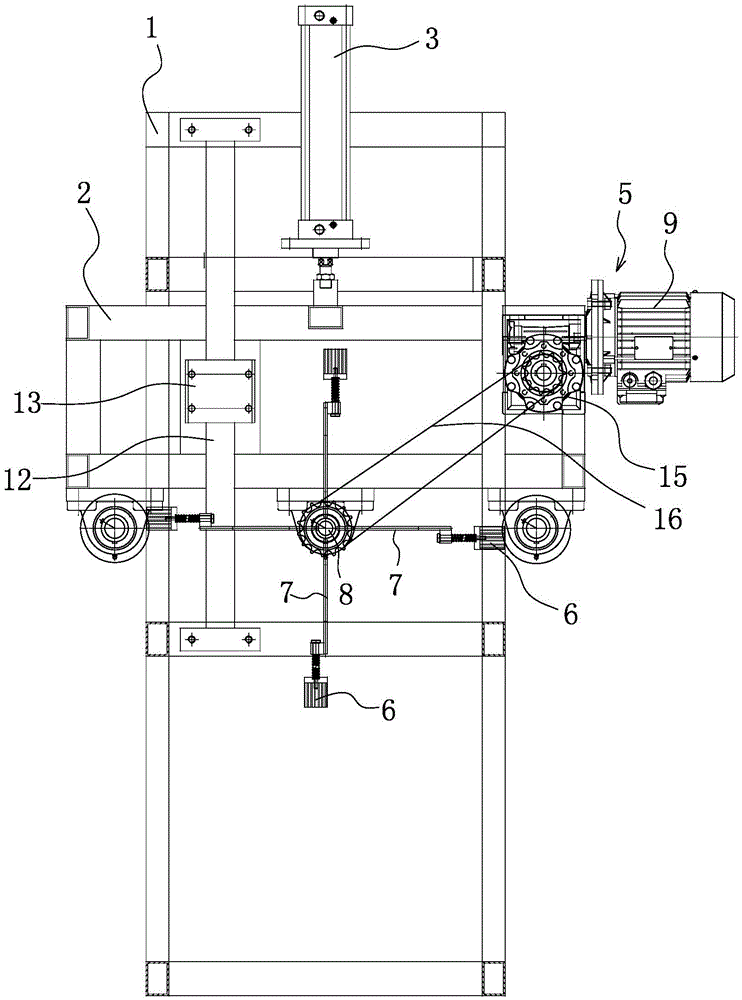

[0024] Such as Figure 1-2 As shown, a pipe mold cleaning mechanism includes a frame 1, a brush frame 2 that is movably connected with the frame 1 is provided in the frame 1, and a brush frame 2 that can drive the brush frame 2 along the vertical direction is fixed on the frame 1. The reciprocating brush frame drive mechanism 3, the brush frame 2 is rotatably connected with a brush plate assembly 4 with a number of brushes 6 fixed on the edge, when the brush frame 2 moves down, the brushes 6 can contact the inner wall of the pipe mold 100, so The above brush holder 2 is also fixed with a brush drive mechanism 5 capable of driving the brush assembly 4 to rotate. Those skilled in the art should understand that the brush 6 can be a hair brush or a metal brush, but the hardness of the bristles should be less than that of the pipe mold 100, so as to prevent the pipe mold 100 from being scratched. Preferably, the brush 6 is a copper brush. Those skilled in the art should also under...

Embodiment 2

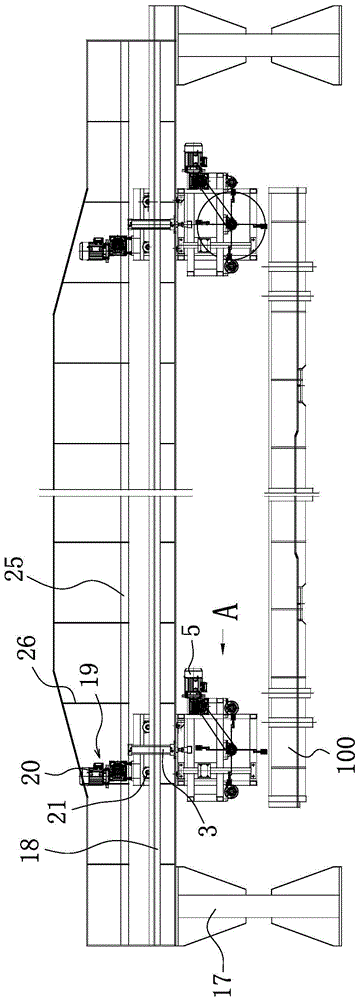

[0032] This embodiment provides a pipe mold cleaning machine, the structure and working principle are basically the same as in Embodiment 1, the difference is that, as Figure 3-4 As shown, the pipe mold cleaning machine includes a beam frame 17, a guide rail 18 is fixed on the beam frame 17, the frame 1 is slidably connected with the guide rail 18, and the frame 1 is fixed with a drive frame 1 along the The frame drive mechanism 19 for axially reciprocating movement of the guide rail 18 . That is to say, when the pipe mold 100 is fixedly placed on the ground, the pipe mold 100 can be completely cleaned by driving the frame 1 to reciprocate through the frame driving mechanism 19 .

[0033] Frame driving mechanism 19 comprises the frame driver 20 that is fixed on the frame 1 and some frame rotating shafts 21 that are rotationally connected with frame 1, and frame driver 20 can be motor, also can be hydraulic motor, wherein a frame rotating shaft 21 and the frame driver 20 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com