Block distributed type multi-printing-head 3D printing device with parallel-connection transverse beams and printing method

A 3D printing and printing device technology, applied in the direction of additive processing, etc., can solve the problems of low working efficiency of a single print head, shorten the printing range of a single print head, and cannot meet the needs of large-scale building construction, so as to reduce the printing range , Improve printing efficiency and prevent vertical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

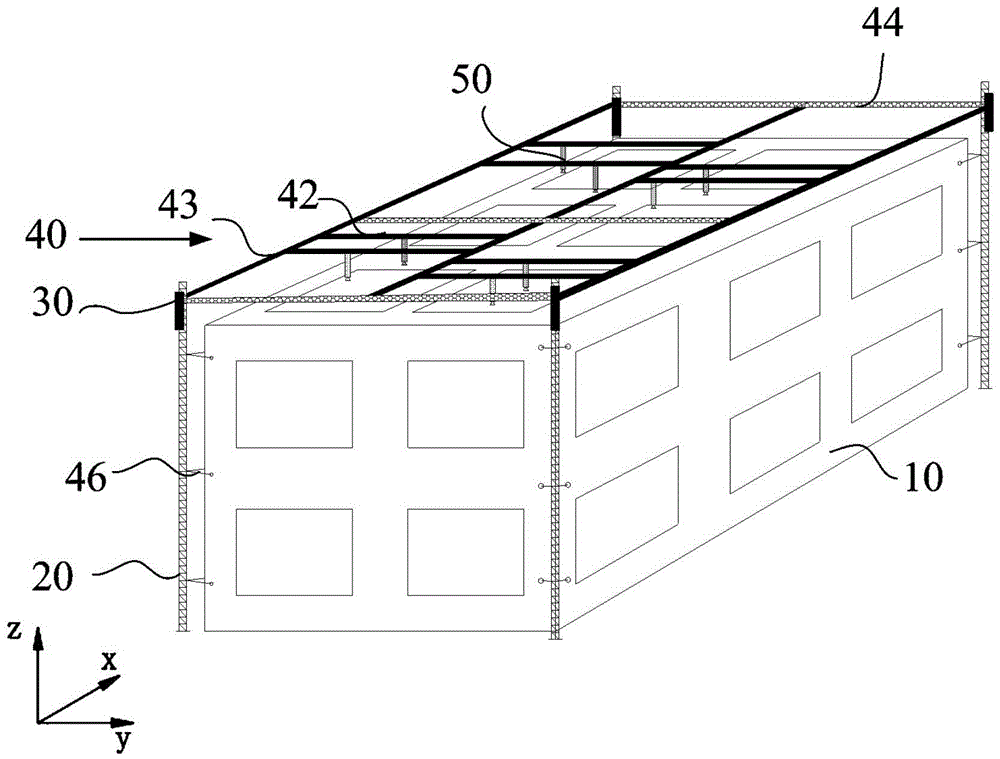

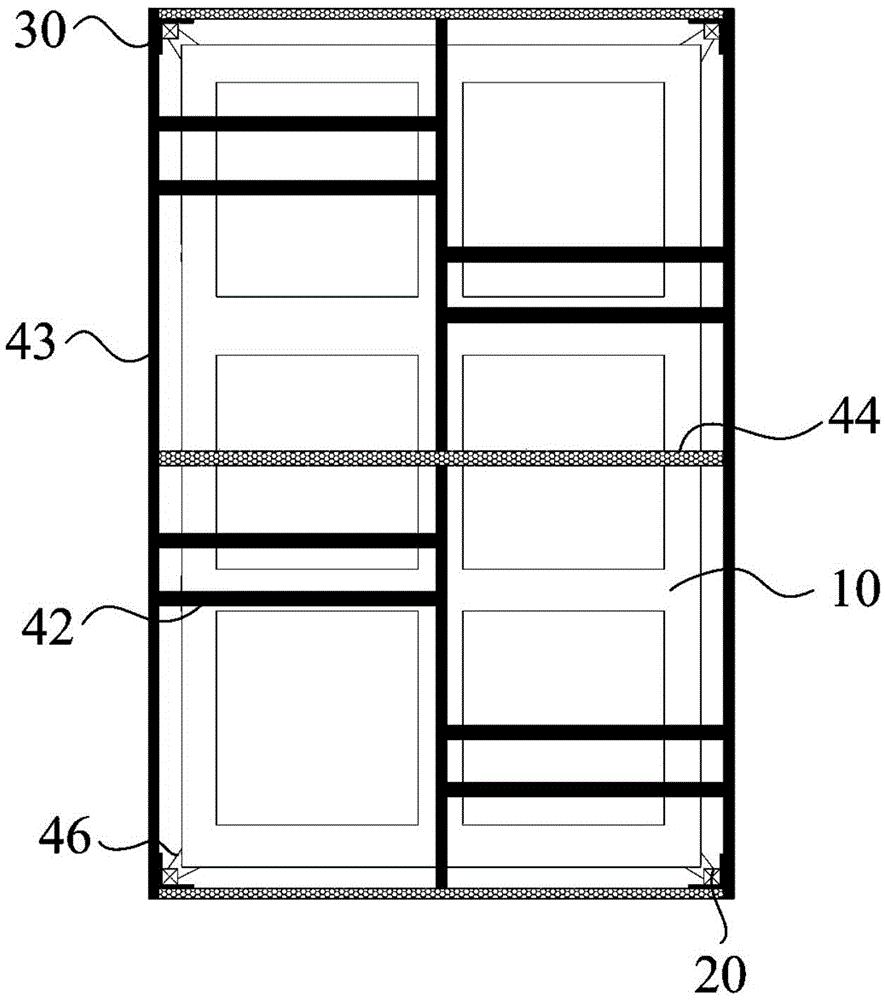

[0030] Combine Figure 1 to Figure 4 To illustrate the block-distributed multi-print head beam parallel 3D printing device of the present invention, this embodiment takes the 3D printing construction of a large building as an example. In order to clarify the direction relationship, the z-axis direction is set as the printed building as needed. The xyz rectangular coordinate system of the height extension direction of the body 10.

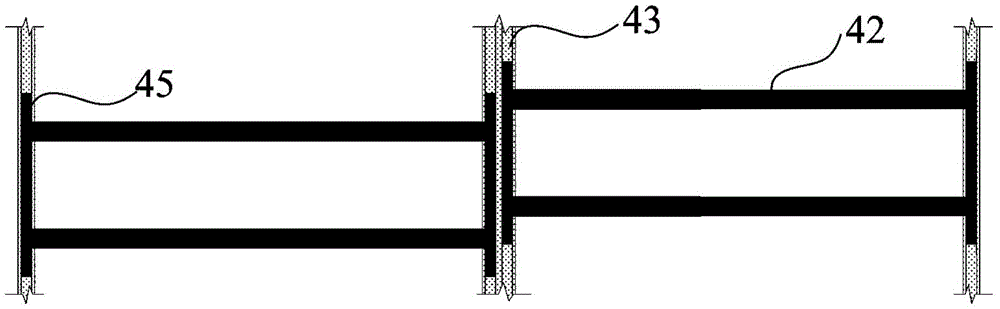

[0031] Please refer to Figure 1 to Figure 4 The above-mentioned block-distributed multi-print head beam parallel 3D printing device includes a climbing guide rail 20 fixed to the outer facade of the printed building body 10, and can move vertically (climbing or climbing) relative to the printed building body 10 along the climbing guide rail 20 Descending) climbing member 30, and a printing device 40 located on the top of the printed building 10 and rigidly connected to the climbing member 30; the printing device 40 includes a rail frame (not shown) r...

Embodiment 2

[0042] Combine Figure 1 to Figure 4 To illustrate the printing method of the block-distributed multi-print head beam parallel type 3D printing device of the present invention, this embodiment takes the construction of a building with an elevation of ±0.000 as an example, and the specific steps are as follows:

[0043] S001: Install a block-distributed multi-print head beam parallel 3D printing device to make the rail frame stably attached to the facade of the printed building 10, so that the print head 50 of the printing device 40 is located at an appropriate height above the printed building 10 , And in the initial position;

[0044] S002: Send a control instruction to the printing device 40 through the power control system to make each print head 50 move along the corresponding print head beam 42 while ejecting building materials. Each time the print head 50 prints a line, the print head beam 50 moves along the slide Set the distance, repeat this cycle to complete the printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Telescopic range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com