High-efficiency water-saving cleaning device for guide belt of rotary screen printing machine

A rotary screen printing and cleaning device technology, applied to printing machines, printing, general parts of printing machinery, etc., can solve the problems of incomplete cleaning of printing guide belt dirt, waste of lotion resources, poor cleaning effect, etc., to achieve Reduce labor intensity, improve cleaning effect, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

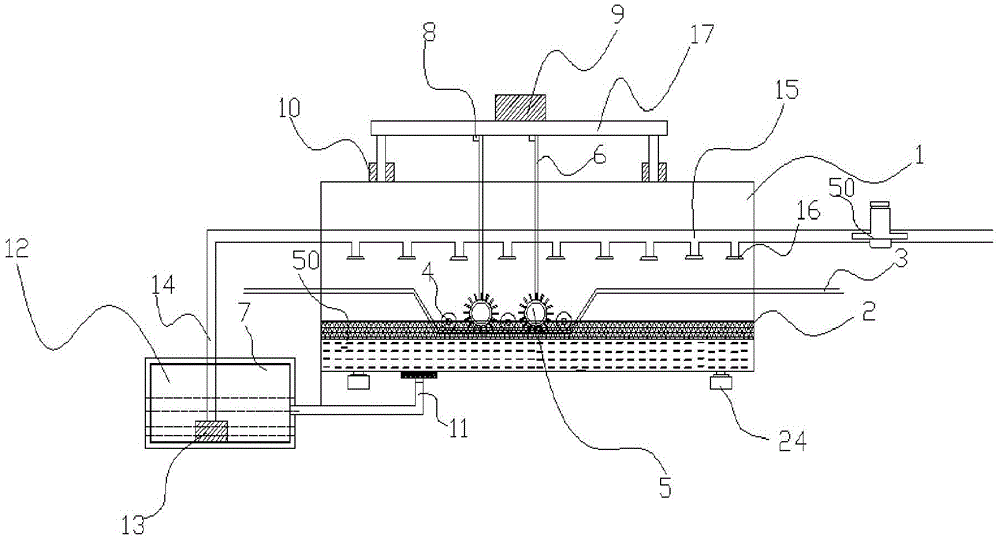

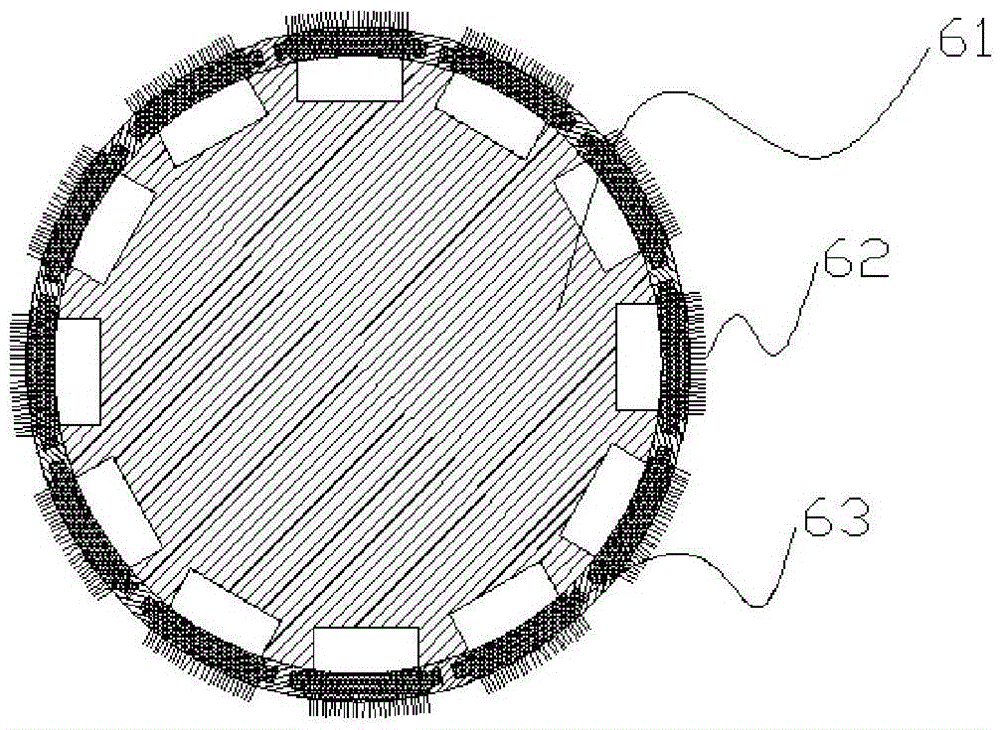

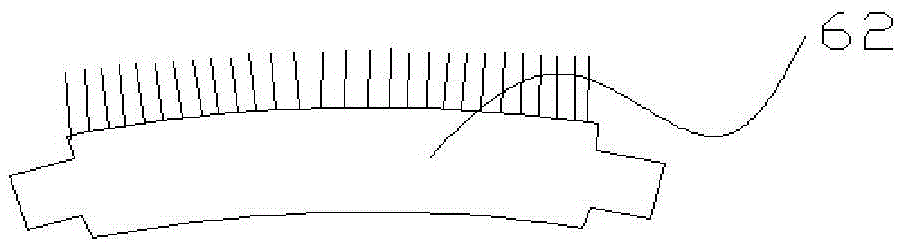

[0019] Such as figure 1 As shown, a high-efficiency water-saving rotary screen printing machine guide belt cleaning device includes a water tank 1, a screen 2, a printing guide belt 3, a belt roller 4, a brush roller 5, a connecting rod 16, a slide rail 17, a limiter Bit block 8, driving motor 9, lifting device 10, water outlet pipe 11, water storage tank 12, booster water pump 13, water inlet pipe 14, water spray pipe 15 and nozzle 6, it is characterized in that, described water tank 1 is cuboid structure, Its lower part is provided with two cylinders 24 for driving the water tank 1 up and down, the middle position of the water tank 1 is provided with a screen 2, the screen 2 is fixed on the inner wall of the water tank 1, and the upper side of the screen 2 is provided with Brush roller 5, said brush roller 5 is installed on the bottom of connecting rod 16 and is in contact with the top surface of printing guide belt 3, said connecting rod 16 upper side is connected with slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com