Gas path control system for vehicle lift bridge

A kind of air circuit control, vehicle technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

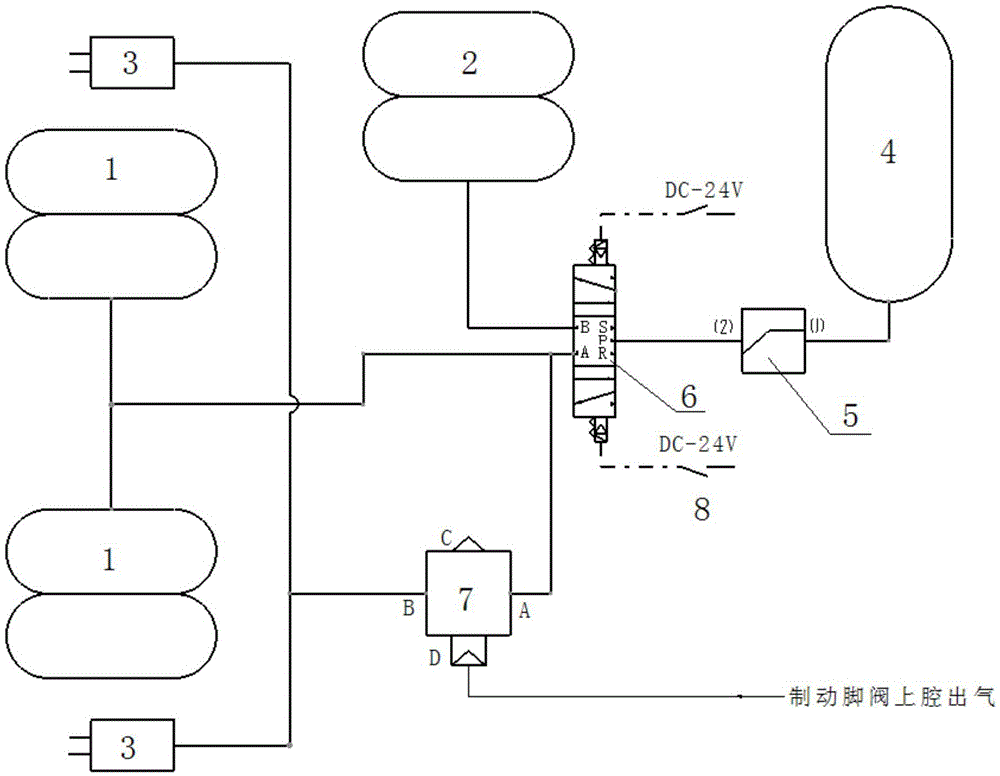

[0013] figure 1 It is a schematic diagram of the air circuit control system used in the lifting axle of the vehicle according to the present invention. Depend on figure 1 It can be known from the structure shown that this kind of air circuit control system for vehicle lift axles includes a lifting control air circuit composed of a load-carrying air bag 1, a lifting air bag 2, an air storage tank 4, a pressure regulating valve 5, a solenoid valve 6 and a switch 8, and The brake control air circuit is composed of the brake chamber 3, the air storage tank 4, the pressure regulating valve 5, the solenoid valve 6, the relay valve 7 and the switch 8, and the carrying airbag 1 passes through the solenoid valve 6 and the pressure regulating valve 5 is connected to the air storage tank 4, the air chamber 3 is connected to the branch road connecting the carrying air bag 1 and the electromagnetic valve 6 through the relay valve 7, and the lifting air bag 2 is connected to the air storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com