Full-automatic plastic packaging machine and packaging method thereof

A packaging machine, fully automatic technology, used in packaging machines, packaging, wrapping paper, etc., can solve the problems of large capital construction investment, high noise from the air source, and high power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be described in further detail below in conjunction with the accompanying drawings.

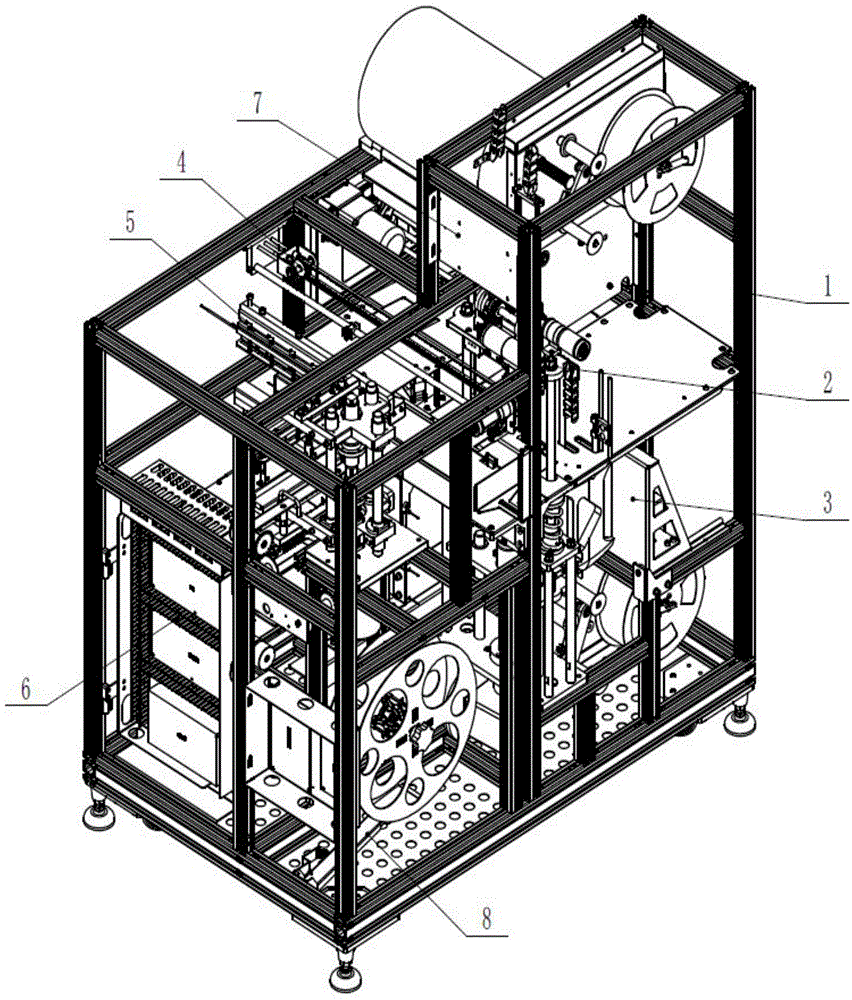

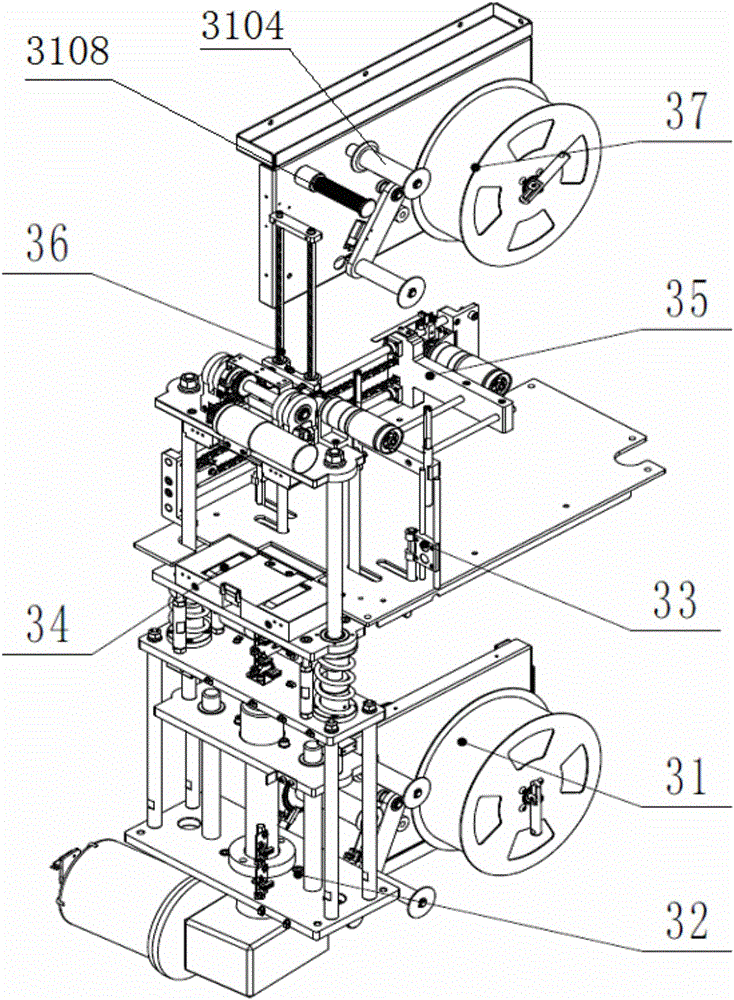

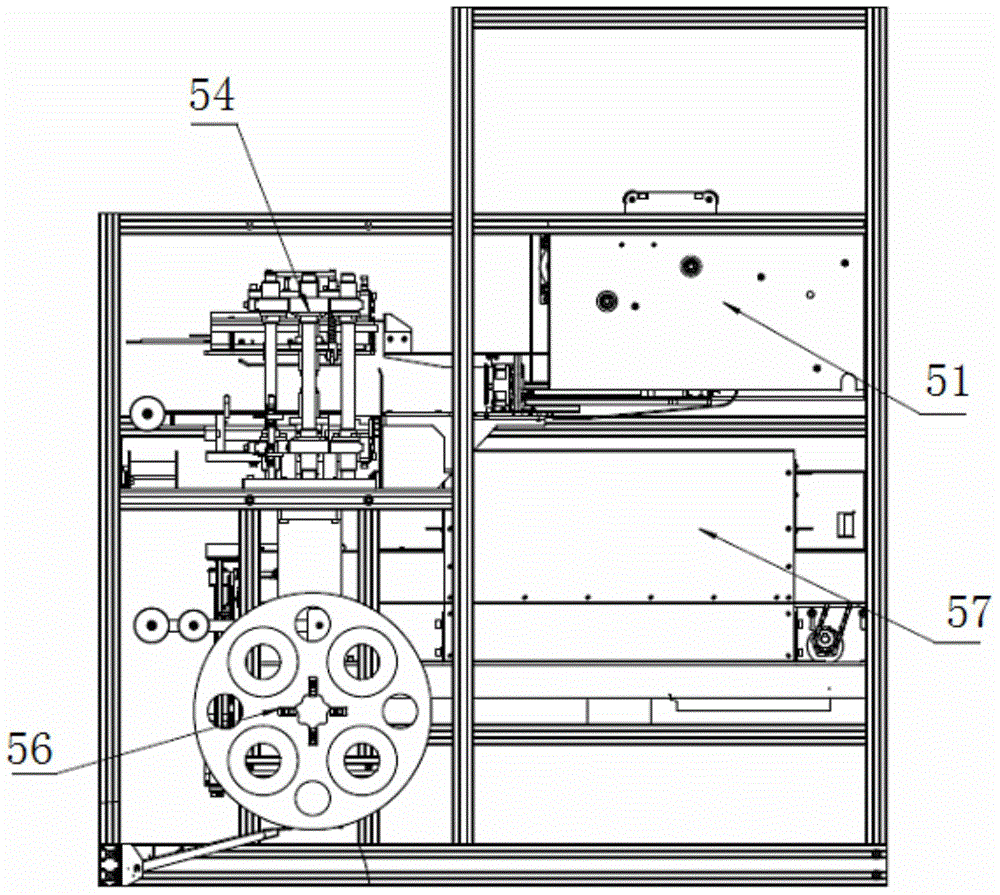

[0083] Such as figure 1 As shown, the present invention includes a frame 1, a logo printing unit 2, a binding unit 3, an intermediate transmission unit 4, a package heat shrinking unit 5, a drive system 6, a control system 7 and an early warning system 8, wherein the frame 1 is from top to bottom Divided into multiple installation areas by several partitions, the logo printing unit 2 is set in the frame 1 and is located on one side of the strapping unit 3, which is used to print labels on the plastic tape before strapping, and the strapping unit 3 is set on the frame 1 The front side is used to bundle the packaged objects together. After the packaged objects are bundled, they are sent to the packaging heat shrinking unit 5 through the middle transmission unit 4, and the bundled objects are packaged and heat-shrinked through the packaging heat shrinking unit 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com