Filtering device for particle oil in printing and dyeing aqueous liquid

A technology of granular oil and printing and dyeing water, applied in filtration treatment, grease/oily substance/float removal device, textile industry wastewater treatment, etc. To achieve the effect of good degreasing effect, convenient replacement and lower maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

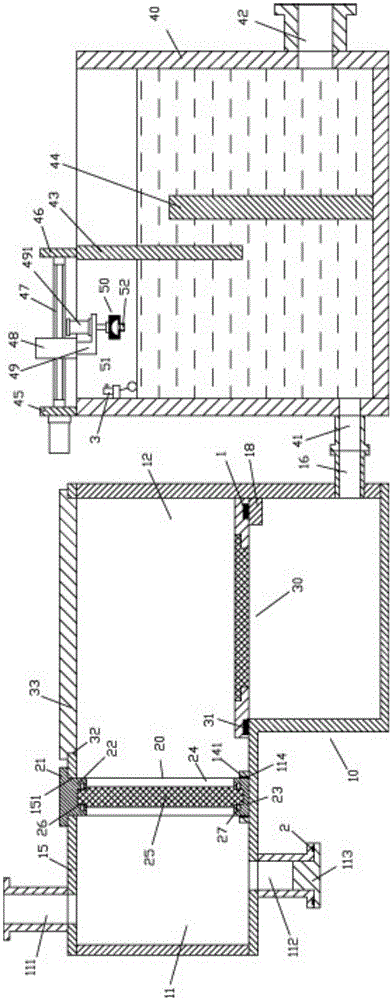

[0028] Examples, see e.g. Figure 1 to Figure 5 As shown, a printing and dyeing water particle oil filter device includes a filter box 10 and an oil removal filter box 40, and the filter box 10 includes a left filter box 11 and a right filter box 12, and the right filter The bottom plate of the box body part 12 is lower than the bottom plate of the left filter box body part 11, and the upper part of the filter box body 10 is fixed with an upper plate body 15, and the upper part of the upper plate body 15 is connected with a liquid inlet pipe at the upper part of the left filter box body part 11 111, the bottom plate of the left filter box body 11 is connected with a particle discharge pipe 112, and the bottom end of the particle discharge pipe 112 is fixed with a plug 113;

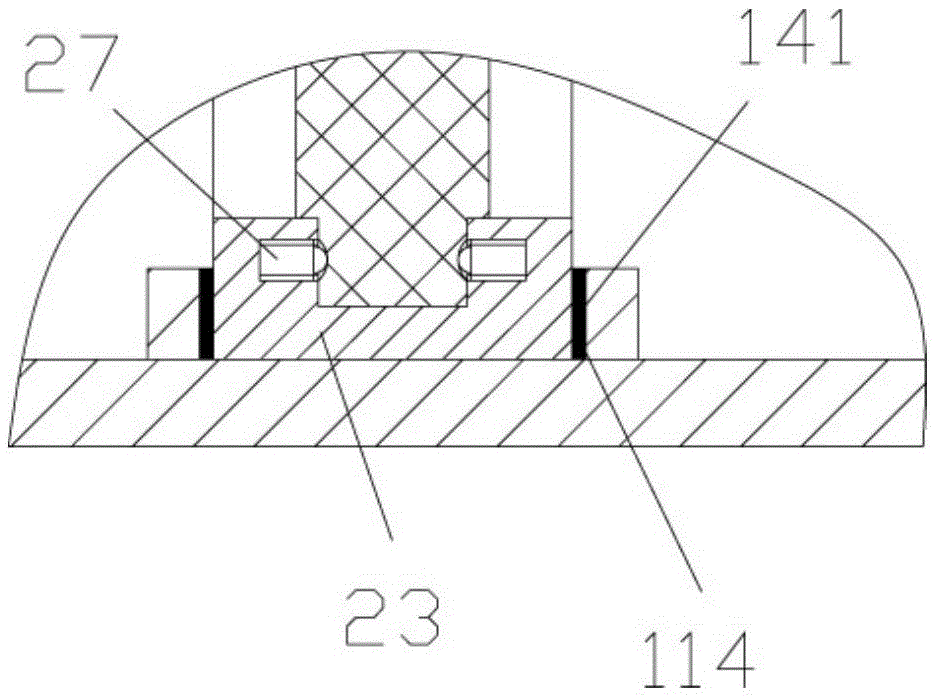

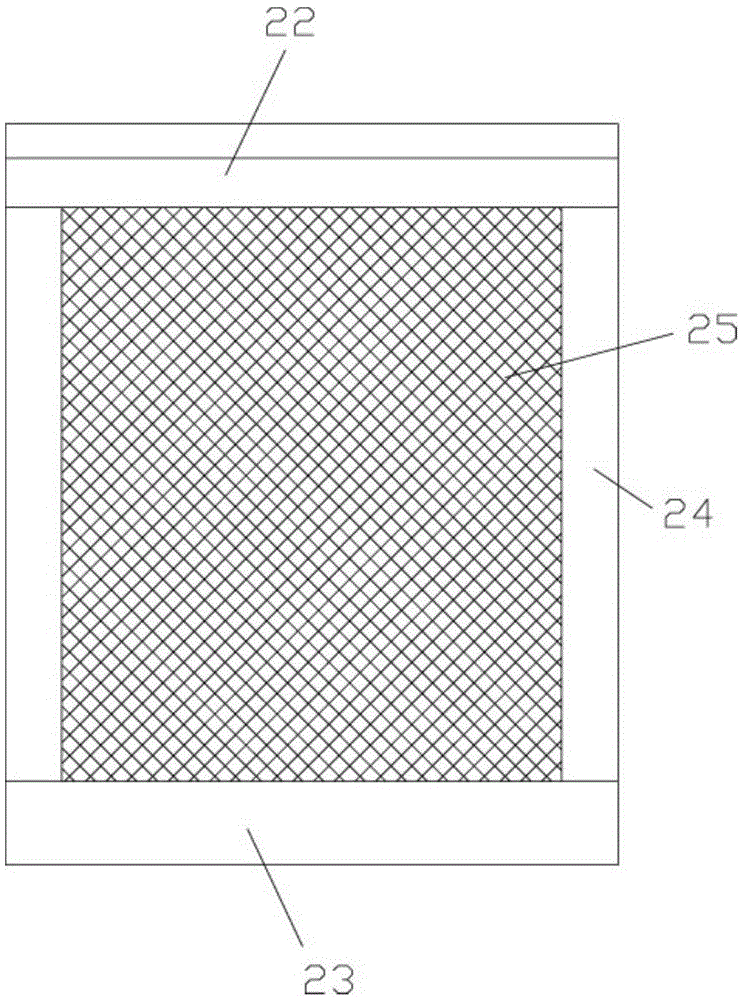

[0029] There is a slot 14 on the bottom plate at the right end of the left filter box body part 11, and the upper plate body 15 just above the slot 14 has a vertical jack 151, and the first filter screen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com