Pulverized coal injection delivery system for lime kiln

A technology of conveying system and pulverized coal injection, which is applied in the field of lime kiln supporting equipment and lime kiln pulverized coal injection conveying system. capacity, reduce power consumption, and optimize the delivery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

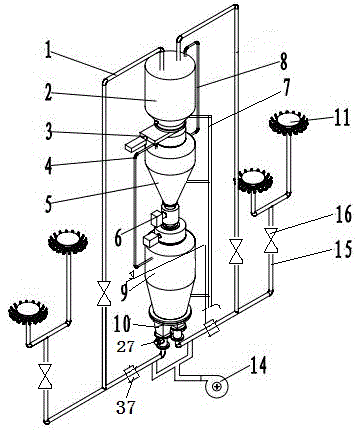

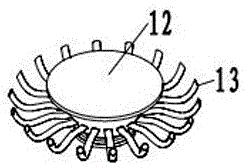

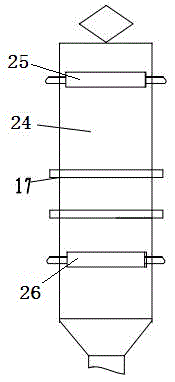

[0019] The lime kiln pulverized coal injection conveying system of the present invention is as figure 1 As shown, it includes a pulverized coal bin 2, a tundish 5, an injection tank 9, a fan and 4 pulverized coal distributors 11, and the fan is a Roots blower. The pulverized coal bin is connected to the intermediate tank through the gate valve 3, and the intermediate tank is connected to the injection tank 9 through the feed valve 6. The bottom of the spray tank is provided with a pulverized coal discharge port 10, which is connected to the pulverized coal distributor 11 through a feed valve 27 and a pulverized coal delivery pipe 15, and the fan is connected to the pulverized coal delivery pipeline. The system is equipped with a powder return pipeline 1, a balance pipeline 4 and an upper balance pipeline 8. The pulverized coal delivery pipe is connected to the pulverized coal bin through the powder return pipeline, the injection tank is connected to the intermediate tank throu...

Embodiment 2

[0022] Another embodiment of the present invention is as Image 6 As shown, the injection conveying system and the sleeve kiln 31 are included. The injection conveying system includes a pulverized coal bin 2, a tundish 5, an injection tank 9, a fan and 4 pulverized coal distributors 11, and the sleeve kiln is equipped with a combustion Chamber 32, the combustion chamber is provided with sleeve kiln pulverized coal burner 33. Figure 7 As shown, the pulverized coal burner of the sleeve kiln is provided with a pulverized coal inlet 34, an air inlet 35 and a burner port 36, and the distribution branch pipe 13 is connected to the pulverized coal inlet of the pulverized coal burner of the sleeve kiln. Other structures and operations of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com