Thermoplastic elastomer raw material for earphone cable and manufacturing method thereof

A thermoplastic elastomer and a manufacturing method technology, which are applied to the thermoplastic elastomer raw material and the application field of the manufacture of high-transparency earphone cables, can solve the problems of insufficient softness, poor weather resistance, etc., and achieve simple technical realization, soft feel, and processing. Economical and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment discloses a thermoplastic elastomer raw material, the thermoplastic elastomer raw material is used to manufacture high-transparency earphone wires, and the earphone wires using the thermoplastic elastomer raw material have the characteristics of high transparency, soft and smooth feel.

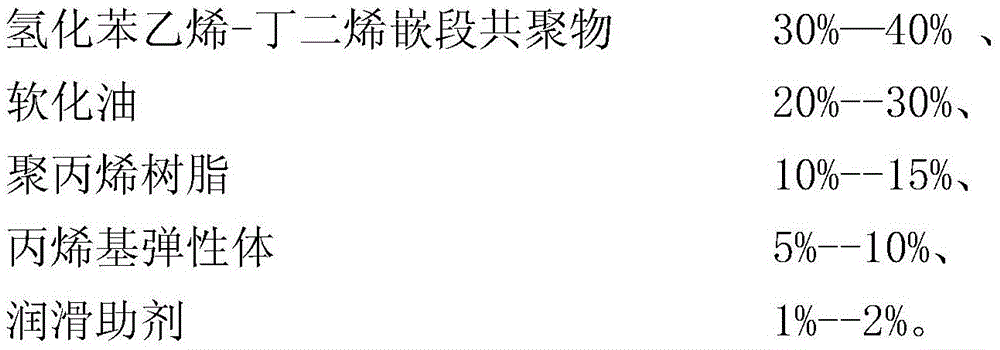

[0025] Its components include: hydrogenated styrene-butadiene block copolymer, softening oil, polypropylene resin, propylene-based elastomer and lubricating aid, and it is characterized in that, based on the sum of the weights of the above-mentioned components, each of them The group distribution ratio is:

[0026]

[0027]

[0028] The hydrogenated styrene-butadiene block copolymer (styrene-butadienetriblockcopolymer, referred to as: SBS) is a white loose columnar solid, chemical characteristics: the relative molecular weight of SEBS has a great influence on the performance, the relative molecular weight is large, and the solution viscosity is large , High bonding...

Embodiment 2

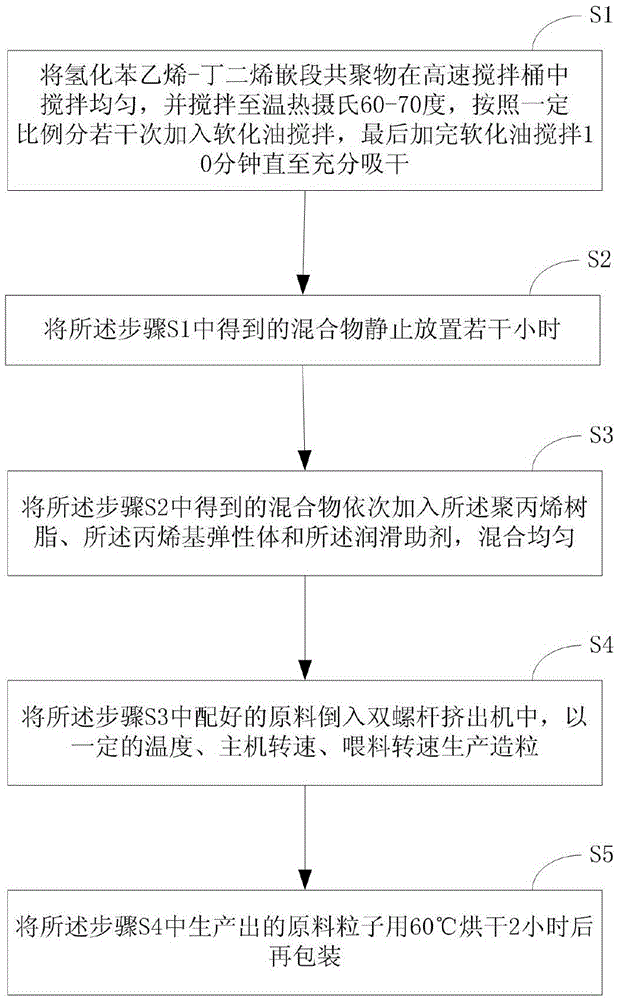

[0034] See figure 1 , figure 1 It is a flowchart of a manufacturing method for a thermoplastic elastomer raw material used for earphone wires disclosed in this embodiment. figure 1 A manufacturing method of a thermoplastic elastomer raw material is shown, which is used to manufacture thermoplastic elastomer raw materials for manufacturing earphone wires. The earphone wires using the thermoplastic elastomer raw materials not only have high transparency, but also have fine and soft touch and weather resistance Strong features.

[0035] Such as figure 1 As shown, the manufacturing method includes the following steps:

[0036] S1. Stir the hydrogenated styrene-butadiene block copolymer evenly in a high-speed mixing tank, and stir until warmed to 60-70 degrees Celsius, add the softened oil several times according to a certain proportion and stir, and finally add Stir the softened oil for 10 minutes until fully absorbed;

[0037] S2, placing the mixture obtained in the step S1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com