Adhesive-free briquette coking method

A binder-free, coal coking technology, used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of increasing coking costs, unfavorable for enterprises to reduce costs and increase efficiency, and achieve strong equipment versatility and thermal strength. The effect of improving indicators and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

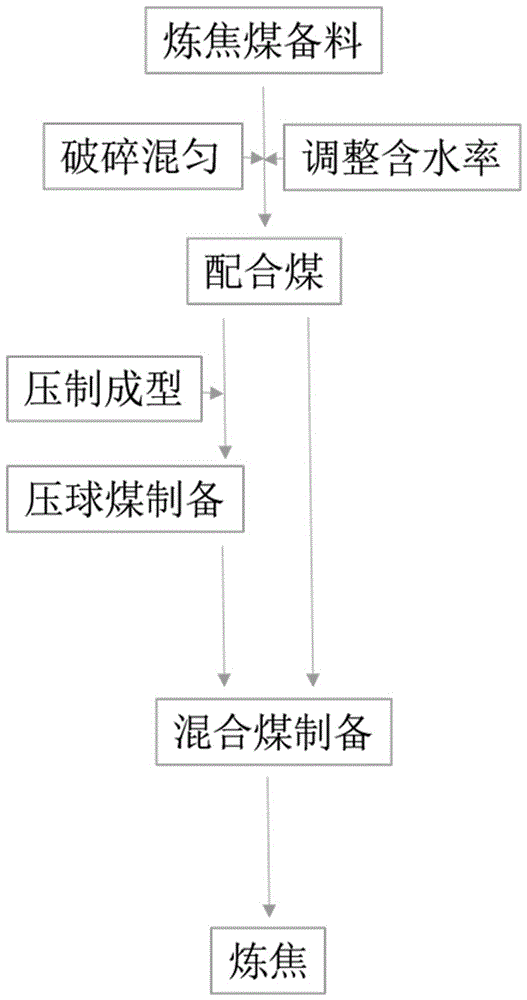

Method used

Image

Examples

Embodiment 1

[0027] The coal blending structure is calculated by weight ratio: Bochi main coking coal 10%, mixed main coking coal 35%, mixed 1 / 3 coking coal 30%, Panz coal 15%, 1 / 3 coking coal 10%, with a total weight of 268.00kg.

[0028] Weigh the corresponding coal material according to the set coal blending structure, crush it until the particles with a particle size of <3mm account for 86.5% of the total coal material, mix well, and adjust the moisture content to 8% to obtain the blended coal. Send 25% of the blended coal into the roller forming briquetting machine, and make 67.00kg of briquetting coal with a forming pressure of 30kg. Mix the briquette coal with the remaining 201.00kg of mixed coal to make 268.00kg of mixed coal with a moisture content of 8%. Put the mixed coal into a 200kg coke oven, dry distillation at 1050~1010℃ for 17h, and then get 198.58kg of target coke.

[0029] The index test shows that: the volatile content of blended coal is 26.25%, the compressive strengt...

Embodiment 2

[0031] The coal blending structure is calculated by weight ratio: Bochi main coking coal 10%, mixed main coking coal 35%, mixed 1 / 3 coking coal 30%, Panz coal 15%, 1 / 3 coking coal 10%, with a total weight of 260.00kg.

[0032] Weigh the corresponding coal material according to the set coal blending structure, crush it until the particles with a particle size of <3mm account for 85.5% of the total coal material, mix well, and adjust the moisture content to 12% to obtain the blended coal. Send 25% of the blended coal to the double-roll forming briquetting machine, and make 65.00kg of briquette coal with a molding pressure of 40kg. The compressive strength of the briquette coal is 170~190N / ball. Mix the briquette coal with the remaining 195.00kg of mixed coal to make 260.00kg of mixed coal with a moisture content of 12%. Put the mixed coal into a 200kg coke oven, dry distillation at 1050~1010℃ for 16h, and then get 195.05kg of target coke.

[0033] The index test shows that: the...

Embodiment 3

[0035] The coal blending structure is calculated by weight ratio: 10% high-ash Ngui main coking coal, 35% mixed main coking coal, 30% mixed 1 / 3 coking coal, 15% Panz coal, 10% high-ash 1 / 3 coking coal, total weight 265.00 kg.

[0036] Weigh the corresponding coal material according to the set coal blending structure, crush it until the particles with a particle size of <3 mm account for 86.0% of the total coal material, mix well, and adjust the moisture content to 10% to obtain the blended coal. Send 20% of the blended coal to the roller forming briquetting machine, and make 53.00kg of briquette coal with a molding pressure of 25kg. The compressive strength of the briquette coal is 170~190N / ball. Mix the briquette coal with the remaining 212.00kg of mixed coal to make 265.00kg of mixed coal with a moisture content of 10%. Put the mixed coal into a 200kg coke oven, dry distillation at 1050~1010℃ for 16.5h, and then get 198.00kg of target coke.

[0037] The index test shows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com