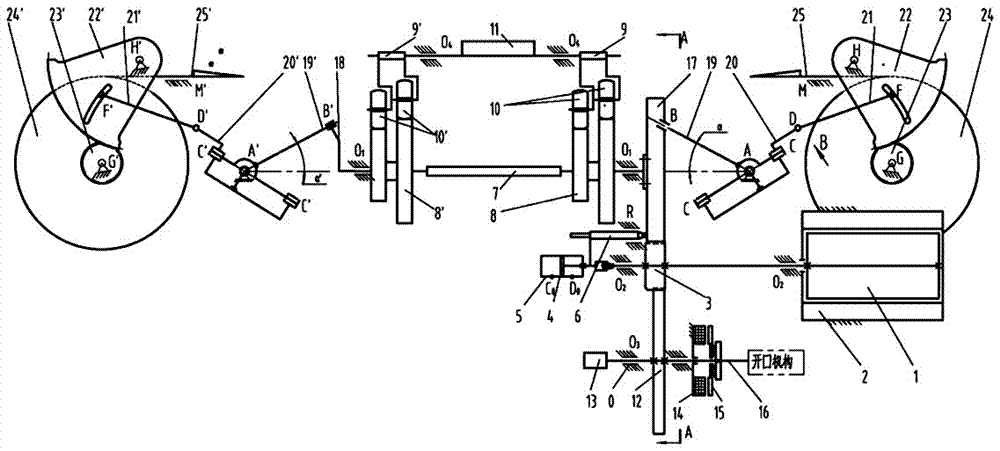

A super-start rapier loom main drive system and normal, slow and weft-seeking motion methods

A technology of the main drive system and rapier looms, which is applied in looms, textiles, papermaking, textiles, etc., to achieve the effect of fewer motion pairs and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

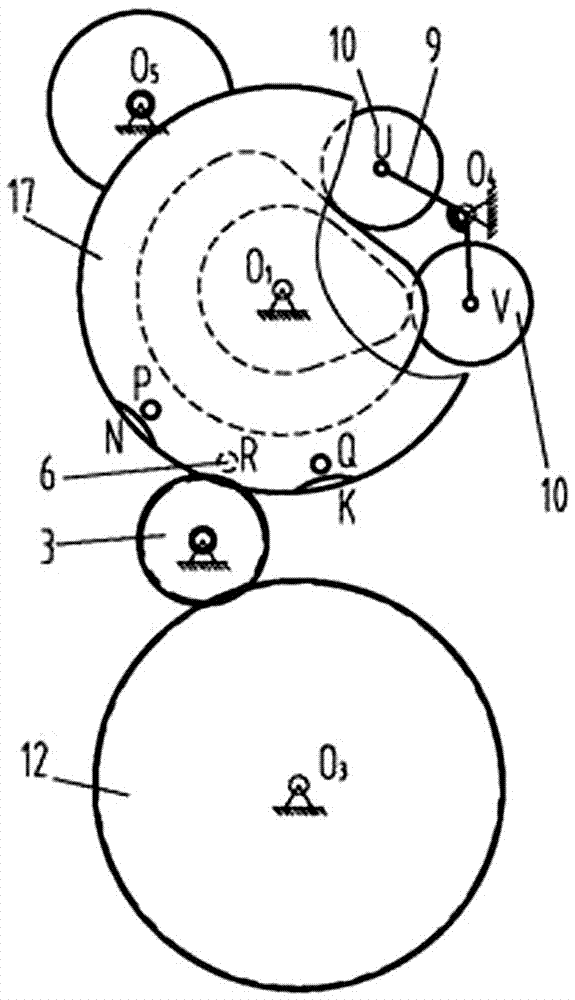

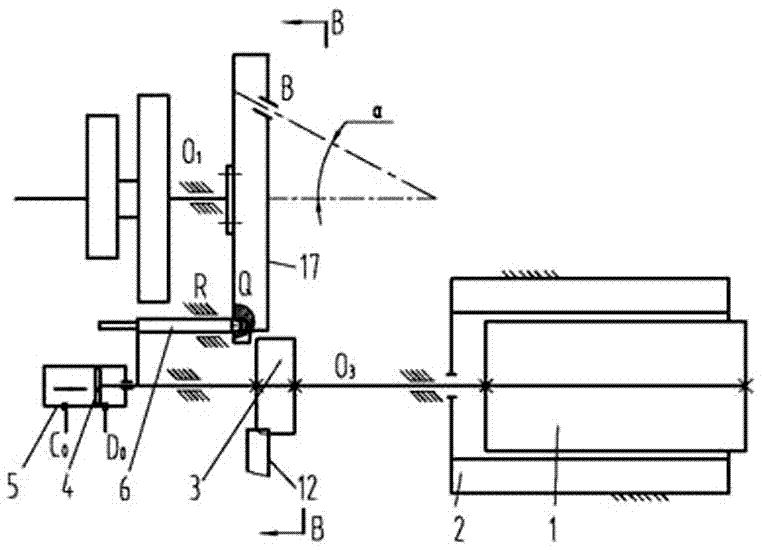

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings: a main drive system of a super-start rapier loom, which mainly includes: the gear shaft 103 of the main motor is fixedly connected with the rotor 101, and is connected with the frame 100 through a bearing to form an O&O 2 The rotating pair; the brake armature is fixedly connected with the rotor 101 through the spring, and the brake coil 122 is fixedly connected with the frame 100; the transition gear 124 meshed with the gear shaft 103 is connected with the frame 100 through a bearing, forming an OO 3 Cylindrical pair, connected with piston 104, forming OO 3 'rotating pair; the pin gear 106 is fixedly connected with the piston 104, and forms an RR cylinder pair with the frame 100, which can move along the guide hole on the frame 100; the piston 104 is fixedly connected with the piston cylinder on the frame 100 105 forms the cylindrical pair connection, cooperates with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com